You can check out the full article here.

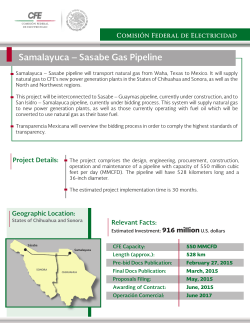

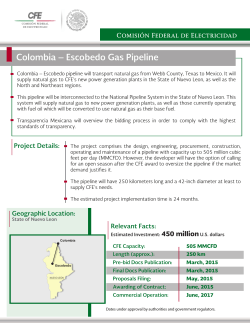

Composite comfort Tim Mally, Citadel Technologies, USA, explores how carbon fibre composite repair systems are rapidly gaining traction in the budget-minded and engineering driven oil and gas industry as an acceptable method to restore pipeline integrity. W ith the recent plunge in oil prices on the West Texas Intermediate (WTI) dropping below US$50/bbl, oil and gas operators are scrambling to thin out labour and trim down the fat on their operating budgets. Meanwhile, lower operating budgets have not absolved their responsibility to maintain a safe and reliable pipeline network managed through a pipeline integrity management programme. To add to the chaos, many pipeline safety regulators around the world, such as the US’ Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (US DOT’s PHMSA), are cracking down on ageing and potentially unsafe pipeline infrastructure within their respective countries. The only item that seems to be increasing as fast as the amount of pipeline regulations is the cost of the penalties for non-compliance. As these two factors constantly swirl in pipeline owners and operators’ minds, they are daily faced with decisions of which outcomes will directly effect how efficiently and economically they can Figure 1. BlackDiamond® is leading a composite repair revolution that is helping to change the way that pipeline operators approach their everyday integrity digs. keep their pipelines safe and intact for the surrounding population. With budgets and safety setting the stage at the forefront of their minds, operators are looking for trusted tools that can safely and economically repair and maintain their pipelines. Enter carbon fibre composite repairs as a safe and reliable means of saving money and restoring pipeline integrity. One composite repair that operators have placed their trust in is BlackDiamond®, which is a strength restoring blend of aerospace-grade carbon fibre and high quality two-part epoxy. Manufactured by Citadel Technologies in Tulsa, Oklahoma, BlackDiamond has been developed, laboratory tested and designed by engineers specifically for the pipeline industry. The engineering staff at Citadel Technologies have partnered with several pipeline operators over the years to utilise BlackDiamond to solve common integrity issues with ease in the field. These operators sleep well at night, knowing that they are using a product to repair their pipelines that has been rigorously tested in the laboratory and proven with successful applications worldwide. This unique blend of peer-reviewed testing and field experience is rapidly bringing unprecedented industry acceptance to advanced composite repair systems as a means of restoring pipeline integrity. Composite science Figure 2. BlackDiamond repairs have been installed worldwide for almost 20 years. Figure 3. When properly designed, a BlackDiamond repair is stronger than the original pipe itself. Figure 4. Air-to-ground pipe transitions often experience corrosion and are typically in need of repair. World Pipelines / REPRINTED FROM MARCH 2015 According to the US DOT Code of Federal Regulations (CFR) Parts 192 and 195, “corroded pipe may be repaired by a method that reliable engineering tests and analyses show can permanently restore the serviceability of the pipe.” Although this is a vague definition, the ASME PCC-2 committee has been tasked with quantifying which tests and analyses are needed in order to guide pipeline operators in qualifying composite repairs as an acceptable means of permanent pipeline remediation. ASME PCC-2 Article 4.1 (for non-metallic repairs on high risk piping applications), in particular, provides a roadmap for the qualification testing that a composite repair system must undergo to meet the rigorous pipeline repair criteria of operators around the world. While composite manufacturers previously cornered the market on developing and understanding this article, more and more pipeline operators are diving into the process of editing and contributing to the development of this repair standard. Such a shift in participation can indicate that composites are rapidly gaining acknowledgement as a legitimate permanent pipeline repair option, signalling more widespread acceptance and use from major oil and gas companies. Although optional for the PCC-2 Standard, there are several long-term tests that can be performed on composite repair systems to demonstrate reliability as a “permanent repair solution.” Creep tests, fatigue tests, burst tests, etc. can all be performed on the composite system according to ASTM standards to prove the effectiveness of composite repairs over a long-term design life. BlackDiamond’s repair components have been tested in the lab to have a minimum 50 year life according to creep tests. Figure 3 demonstrates an example of fatigue tests proving that BlackDiamond can survive greater than 110 000 cycles of pressure cycle fatigue and is still stronger than the original pipe. Along with the PCC-2 qualifying tests, these tests more than qualify BlackDiamond as a permanent repair solution in line with DOT regulations. Composite advantage Traditional repair methods, such as full pipe cut out and replacement, welded steel sleeves and clamps, have been accepted industry-wide for longer than composites have been a repair option. To initiate a mindset change among pipeliners who have used these methods for their entire careers is nigh impossible. However, even the staunchest supporter of traditional repair methods would be forced to consider the several advantages that carbon fibre reinforced composites offer upon closer examination. When compared with welded sleeves, maybe one of the clearest advantages of a pipeline integrity-restoring composite repair is the absence of hot works. No welding is required for wet lay up wraps, therefore many of the problems that occur from welding are eliminated. Strength reducing heat-affected zones and stress corrosion cracking can potentially occur when welding on pipelines. Both of these issues reduce pipeline integrity, and are avoided when utilising a composite repair solution. Certified and qualified welders are a precious commodity worldwide. Composite repair installations do not require the same level of schooling and training. Although composite installation training is important and should not be overlooked, a composite repair can be applied by a less experienced labour force much quicker and cheaper than traditional repair methods. Additionally, a BlackDiamond installation can be made in-situ without reducing pipeline pressure and does not require shutdown of the pipeline. Operation of the line in question continues and saves the operator the costs associated with production loss that would otherwise be lost when cutting and replacing or welding a metal sleeve that require the line to be shut down. However, many pipeline operators are not yet ready to completely switch over to composite repairs. For those that are hesitant to diversify from traditional repair methods, there are some situations where composites have the clear advantage over welded metallic repairs. BlackDiamond proves its mettle over traditional repair methods with ease of installation on field bends, pipe fittings, and complex geometries while maintaining desired pipeline production levels. If shutdown is not possible or is too inconvenient for a cut out and replacement, then carbon fibre composite repairs hold a major advantage when repairing these geometries. Welded sleeves are not a valid repair option for many field bends. Wet layup Figure 5. The first step in the process is to fill the external damage with a load transferring filler putty. Figure 6. The use of a bucket enabled certified installers to access the full length of pipe requiring repair. REPRINTED FROM MARCH 2015 / World Pipelines composite repairs are easily manoeuvred to install and cure around these odd shapes, restoring the strength of the pipe in these bends to restore the pipe back to its MAOP. As operators determine whether composite repairs such as BlackDiamond are the right fit for their repair needs, situations such as field bend repairs will help composites quickly gain approval and acceptance within stringent, engineer-driven oil and gas companies. Composite connection One major pipeline operator in the US and Caribbean has been on the cutting edge of pipeline repair technology through the use of composite repairs for many years. As a pioneer in the use of composite repairs, this pipeline operator has expanded their use of BlackDiamond to include the repair of field bends, corrosion anomalies, mechanical damage, and manufacturing defects in the pipe. Roger Clark, Certified Inspector for Pugh Pipeline Services, is a big proponent of using BlackDiamond to restore pipeline integrity for pipeline operators such as this one. According to Roger, BlackDiamond has “saved them [the pipeline operator] a lot of money over traditional repair methods through the years.” This pipeline operator also recognises that BlackDiamond will not only restore his externally corroded and mechanically damaged pipelines to their original operating strengths, but it will also prevent future external corrosion as well. With years World Pipelines / REPRINTED FROM MARCH 2015 of experience under his belt, Roger can spot a potential opportunity to use a composite repair, and is trusted by both the pipeline operator and the composite repair company to carry it out with the utmost efficiency and quality. Roger recently supervised an installation on a 30 ft span of 8 in. dia. pipeline with a field bend where access to the pipe was limited. A welded sleeve was not an option due to the pipe geometry, and the pipeline operator could not afford to shut down in order to cut and replace due to the high demand of the contents within the pipe and the costs associated with a full shutdown. Roger ensured that the BlackDiamond repair was installed by certified installers, and utilised his vast BlackDiamond experiences to organise an assembly line to speed up installation. The engineered composite repair was installed and cured within the day, and returned the pipeline to its original strength to the highest satisfaction of the operator. In cases like this, the pipeline owner knew that they could trust composite repairs to get the job done. A significant body of evidence was presented to prove BlackDiamond’s mettle on the laboratory scale, and a wellqualified team led by an experienced supervisor carried out what would have been an otherwise difficult repair. The pipeline operator will continue to turn to composite repairs in 2015 as a suitable pipeline repair method that may soon be the worldwide repair of choice.

© Copyright 2026