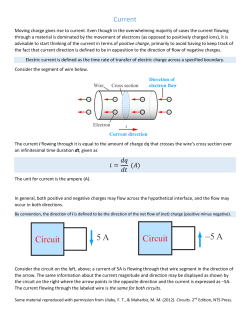

75th anniversary for Ceeco Bartell The best `green` business