HALFEN Accident Recovery Anchor

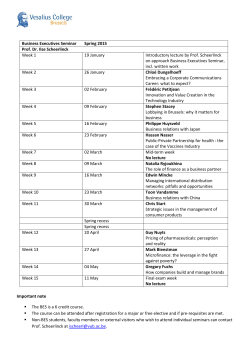

Components of an accident recovery unit The accident recovery unit is installed as a precautionary measure in road tunnels. In the event of an accident crashed vehicles can be effectively and quickly recovered. Increasingly, emergency and accident recovery services demand that suitable accident recovery units are installed every 100 metres in suitable recesses in tunnel walls. The lifting link is similar to the type used for moving precast concrete elements. The HALFEN Recovery anchor system is a cast-in stainless steel spherical head anchor, load class 20,0, with a freely pivoting standard lifting link attached. A securing-bolt is provided to prevent unintentional removal of the lifting link. 20 20 2 18 0 0 Spherical head transport anchor Description Recess formers with threaded rods and wing-nut Load device with pre-drilled hole (Universal head lifting link 6104-12/20), not illustrated: locking pin HALFEN article number HALFEN order number Spherical head transport anchor, stainless steel, load class 20,0 6000-20,0-0180 A4 0735.009-00003 Recess former round, with threaded rods and wing-nut 6232 – 20,0 0736.020-00008 Load device with provision for locking pin to prevent unintentional removal 6104-12/20 0738.009-00001 Chain (to prevent unauthorized removal) Provided by customer Anchor plate with bolt anchor/U-shaped bar, weldable Provided by customer The recess formers are reusable. Please order as many as needed for one concreting section. © 2015 HALFEN · TI-BGA 15-E · www.halfen.de HA L F E N R E C OVE RY ANCHO R S YS TEM Installation and Application Installation Einbau ▸ Constructing the formwork for a tunnel-recess (recommended dimension: see page 4). ▸ The spherical-head anchor is inserted into the recess former and both are then fitted to the formwork. ▸ Drill a hole in the formwork and attach the recess former to the formwork using the threaded bolt and the wing nut. On-site reinforcement / Fixing the anchor-plate: • the tunnel wall must be sufficiently dimensioned for accident recovery; required reinforcement must be installed • additional reinforcement is not required for the transport anchor • an anchor-plate with a head anchor is placed above the transport anchor • the anchor-plate is fixed flush to the top of the reinforcement Ensure the recess former is properly closed and is completely flush with the formwork. Entfernen der Aussparungskörper ▸ After the concrete has set, remove the wing nut. The formwork can now be removed. ▸ Use two metal rods as shown in the illustration to remove the recess former. A hemispherical recess with the anchor head in the middle has been formed. 2 © 2015 HALFEN · TI-BGA 15-E · www.halfen.de HA L F E N R E C OVE RY ANCHO R S YS TEM Installation and Application Attaching the clutch ▸ The lifting link can be attached after removing the recess former. The finished recesss after removing the formwork and the recess former ▸ When connecting the lifting link ensure the tongue points in the direction of the link. Attaching the link ▸ Insert the retaining pin; the pin prevents unintentional release of the lifting link while allowing it to be turned. Retaining pin A chain can be installed to prevent theft of the recovery anchor. The chain is passed through the handle and a u-shaped bar inserted in the two chain ends. The u-shaped bar with the chain-ends is welded to the cast-in metal plate. Attached recovery anchor; not secured with a chain © 2015 HALFEN · TI-BGA 15-E · www.halfen.de 3 HA L F E N R E C OVE RY ANCHO R S YS TEM Installation and Application Recommended dimension for an accident recovery anchor wall-recess 15 98 46 26 15 90 20 Access path 26 26 54 90 142 36 15 16 26 26 26 horizontal section with anchor attached front view Tender example for the accident recovery system Deliver and install a load class 20,0, spherical head transport anchor, length 170 mm. In stainless steel A4 1.4571/1.4404 with reinforcement. Additional on-site reinforcement is not included. Construct a recess with a back surface area of 60 cm × 120 cm, 20 cm deep with side surfaces at a slant of 30°. Insert the spherical head anchor in a round recess former and secure both to the formwork. Secure the recess former to the formwork with the treaded rod (included with delivery). Place reinforcement around the recess former in the area around the anchor head. T - 103-E - 04/15 Deliver and install a load class 20,0, zinc galvanized, universal head clutch. The clutch is attached to the spherical head anchor after striking the formwork. The universal head clutch load class 20,0 is identified with a permanent unique identification number to facilitate annual safety checks. The clutch is fitted with a device – by the manufacturer – to prevent unintentional release of the clutch from the anchor. A chain fixed with a dowel (with an external thread) and a ring bolt to prevent theft of the recovery anchor is installed. PDF 04/15 horizontal section © 2015 HALFEN GmbH, Germany applies also to copying in extracts. Tunnel floor HALFEN GmbH Liebigstr. 14 ⋅ 40764 Langenfeld ⋅ GERMANY Tel.: +49 - (0)2173 / 970-9025 Fax: +49 - (0)2173 / 970-427 E-Mail: [email protected] www.halfen.com The Quality Management System of Halfen GmbH is certified for the locations in Germany, France, the Netherlands, Austria, Poland, Switzerland and the Czech Republic according to DIN EN ISO 9001:2008, Certificate No. QS-281 HH. © 2015 HALFEN · TI-BGA 15-E · www.halfen.de

© Copyright 2026