Solutions for Time-Weighted Average Canister Sampling.

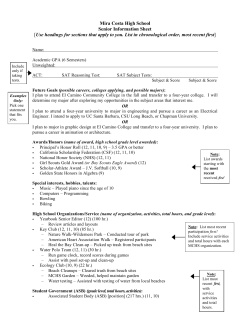

INSTRUMENTS INC. O Cl H H O Cl Cl Cl Cl NH 2 Cl Cl O Cl O Cl O O O O Cl Cl Cl Cl Cl O O NH N H2 O O Cl Solutions for Time-Weighted Average Canister Sampling. CS1200EES_03304115v22 CS1200E Passive Canister Sampler The best solution solu for low level EPA TO-15 monitoring. The CS1200E is a high-purity flow regulation system designed to reliably fill canisters at a constant rate from vacuum to within 1 psi of atmospheric pressure without requiring any power. Unsurpassed flow path inertness and a newly revised flow design enhances TO-15 compound recovery while improving flow stability. No other sampler has scientific data supporting the recovery of sub-PPB level TO-15 compounds. The CS1200E has been verified to fill canisters at a constant rate for up to 2 full weeks! Did you know? Untreated 300 series stainless steel is 67–70% iron, which is very reactive toward many TO-15 compounds. CS1200ES Silonite Coated Passive Canister Sampler Features Time-Weighted Average Sampling Accurately fill 6L Silonite® Canisters with integration times from 1 hour to 2 weeks at more stable and reliable flow rates than any other flow controller and verified recovery of TO-14 / TO-15 compounds. The CS1200E can be also be easily capped off during shipping to prevent any risk of sampler contamination. Why Silonite? Untreated 300 series stainless steel is 67–70% iron, which is very reactive toward many TO-15 compounds. In addition, untreated stainless tubing has an internal oxide layer that readily adsorbs polar and heavier VOCs. The standard CS1200E inlet now comes internally polished, passivated, Silonite® Coated Filter and Inlet Lines and Silonite® coated to insure maximum recovery of all target compounds A large Silonite® coated stainless steel filter is positioned at the inlet to maintain an inert and unobstructed flow path by eliminating particles. CS1200E Inlet lines are electropolished, then Silonite® coated. (An optional Silonite® coating of complete sampler is also available.) – virtually eliminating losses and carryover. The Silonite® coated filter is placed on the inlet to completely eliminate dust and particulate intrusion during sampling. The inlet is capped off to avoid any contamination risk during shipping. McDaniels Controls, Inc.® Gauge Our exclusive gauge with a leak-tight ¼” compression fitting avoids any need for absorptive Teflon® tape in the controller flow path. Sapphire Restrictor Sapphire flow elements provide stable operation from -20˚– 50˚C. Silonite® Filter Inlet Kit w/ Rain Guard – PN: 39-922 39-92204S 204S Table 1 – CS1200E | Restictors and Canister Fill Duration Range CS1200E with stamped flow range code – PN: 39-CS1200E(S)x. Add “S” to order Silonite® Coated version and replace “x” with desired flow code. CS1200E | Restrictor Code Flow Range 1 450mL CS1200E | Canister Fill Duration Range 1L 1.4L 2.7L 600mL 1 40 cc/min. – 160 cc/min. 2 – 10 min. 2 min. – 12 min. 2 13.5 cc/min. – 54 cc/min. 7 – 25 min. 8 min. 3 5 cc/min. – 20 cc/min. 20 – 75 min. 25 min. 4 1.2 cc/min. – 6.8 cc/min. 1 – 3 hrs. 1.2 hrs. – 4 5 0.4 cc/min. – 1.2 cc/min. 3 – 10 hrs. 6 0.2 cc/min. – 0.6 cc/min. • 4 hrs. 3 min. – 15 min. – 30 min. 10 min. – 35 min. – 90 min. 30 min. – 120 min. hrs. – 12 hrs. • 1.5 hrs. – 5 5 hrs. – 15 • hrs. hrs. 8 3.2L 6L 16 min. – 67 min. 20 25 min. – 100 min. 50 min. – 3.3 hrs. 1 hr. – 3.9 hrs. 2 hrs. – 8 hrs. 70 min. – 5 5 hrs. – 20 hrs. min. – 35 min. min. – 80 min. 35 min. – 2.5 hrs. hrs. 2.2 hrs. – 9 hrs. 2.2 hrs. – 10.6 hrs. – 12 hrs. 6.6 hrs. – 26.5 hrs. 7.8 hrs. – 31.3 hrs. 12 hrs. – 2 20 hrs. – 36 hrs. 37.5 hrs. – 3 3 hrs. • • days 44.4 hrs. – 3.5 1 week days 2 days – 7 2 weeks days days TWA Sampling Time-Weighted Average Sampling Accurately fill 6L Silonite® Canisters with Time-weighted VOC concentrations can be determined by sampling into canisters at a constant integration times from 1 hour to 2 weeks with flow rate. The CS1200E allows for a very wide range of constant flow sampling rates by changing demonstrated reliable recovery of EPA TO-14 and the value of the restrictor on the inlet. For any given restrictor, the flow rate can be adjusted by a TO-15 compounds. No other technique can factor of 2–3x. This is easily accomplished by turning a flow adjustment on the vacuum controller collect C1 – C12 compounds quantitatively. body. Sapphire orifices combined with pressure regulation offer superior flow stability when compared to needle valve or frit regulated controllers. Different orifices are available to fill a 6L canister over 1, 3, 8, 24 hours, or even a full 2 weeks. Part numbers for CS1200E flow controllers are Amazing Low-Flow Stability separated by flow range. One flow range can be changed to another by attaching the appropriate More stable and reliable flow rates than any other critical orifice (Codes 1 - 6, see table 1 on previous page for various flow rates). Changing orifices on available flow controller. the CS1200E is much easier than with other flow controllers since no pipe fittings and Teflon® tape is involved. Silonite® coated flow controllers are designated with an “S” following the part number. Silonite® Coated Inlet Lines A Compact and Clean Flow Path The CS1200E features Inlet lines that are The CS1200E includes a high-resolution, McDaniel Controls, Inc. gauge with a ¼” compression electropolished, then Silonite® coated. fitting. This design, exclusive to Entech, completely eliminates messy and absorptive Teflon® tape ler flow path. A threaded inlet cover prevents filter contamination and also acts as from the controller en sampling to prevent moisture from clogging the a rain guard when Silonite® S i Coated Filter rifice. This feature is ideal for sampling in wet inlet filter or orifice. environments, or when performing A large Silonite® Silonit coated stainless steel filter is Silo trace-level measurements with required detection limits below po ositioned at th positioned the inlet to maintain an inert and uno obstructed flow path by eliminating particles. unobstructed ion. 200 part-per-trillion. New Kit Packaging PRESSURE vs. FLOW Our new kit packaging O pa features an integrated 4 acces ssories sories box for f the CS1200E and room for one accessories 3.5 6L Canister, C or four 1.4L MiniCans™. 2.5 2 1.5 Flow Rate, cc/min. 3 NE W ! PN: 29-22062 and 29-22064 1 0.5 0 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 0 Canister Vacuum, in./Hg CS1200E Maintains constant flow rates closer to atmospheric pressure. CS1200EE Passive Canister Sampler and iCan™ shown with our 1L / 1.4L 1.4L MiniCan™ lapsible Quad-Pod stand. collapsible PN N 29-STAND-SAMPQT 29 STAND SAMPQT Dual Can Adapter – PN: 39-99001S Fill 2 canisters accurately for validation by a second laboratory analysis. (Sampler er and Canister sold separately) separatelyy) Collapsible! 2 The Recognized Global Leaders in Environmental Air Analysis. 7200 7650 Preconcentrator 7016D Canister Autosampler 5400B Canister Autosampler Thermal Transfer System 3108D Canister Cleaning System Cl Cl O Cl Cl Cl Cl Cl Cl Cl O O O Cl O Br N O Cl N Cl Cl Cl NH 2 Cl Cl O Cl W NE Le a r n m o re o n l i n e Visit us at www.entechinst.com Entech Instruments, Inc. 2207 Agate Ct. Simi Valley, CA 93065 Phone: 805-527-5939 ! Our new kit packaging is ideal for field sampling. Packaging includes an integrated sampling accesories box plus room for one 6L canister, or four 1.4L MiniCans™. PN: 29-22062 and 29-22064

© Copyright 2026