March 2015 For review vl

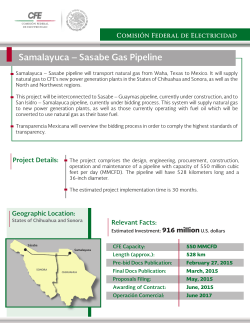

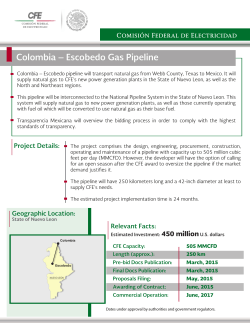

Newsletter - March 2015 Update From The CEO Inside this issue: APGA Rename 2 CPTC Visit 3 Student visit to APA Pipeline 4 Researcher visit to SEAGas Pipeline 5 PRCI Update 6 Researcher Profile 7 Research Update 8 Full Project List 11 Upcoming Events 13 If there is anything you would like to comment on or you would like to offer assistance, please get in touch with me, Valerie Linton. Charles Rottier (the Energy Pipelines CRC Board Chairman) and I have continued visiting APGA RSC members through March and we now have visited or spoken to almost all members. We still have our Sydney visits, plus a few in Melbourne and Brisbane, to complete our rounds, so don’t feel left out if we’ve not got to you yet. We’ve been really pleased with the level of engagement and interest from the APGA RSC members. We picked up quite a few new project ideas and were encouraged by the levels of support offered into those projects. The APGA RSC now have six major construction company members and I will be setting up a constructors user group to help focus ideas in this space. This user group will complement the offshore and plastic/composite pipe user groups established last year and which have really driven research in these areas. Charles and I also attended the APGA launch in Canberra on the 18 March. This was a great event, promoting the change of name and expanded focus of the Australian Pipelines and Gas Association. They were well supported with two Ministers and one Parliamentary Secretary unveiling the new logo! We also had a visit from Richard Wayken, of the Canadian Pipeline Technology Collaboration (CPTC) in the first week of March. We gave Richard the full Energy Pipelines CRC experience, meeting our Board, visiting researchers and attending an APGA RSC meeting. Richard has been very impressed by our organisation and hopes to use it as a model of the establishment of the CPTC. We also hosted a visit from Bill Bruce of DNV GL. Bill met with Paul Grace (Zinfra) and I to discuss progress on a Joint Industry Project (JIP) Bill is running on hot tapping. It is Bill’s intention that the results of the JIP be published once the work is completed and they promise to be very interesting and useful. The Government is nearing the end of its Miles Review of the CRC Program. It is my understanding that the report is either with Minister Macfarlane or is on its way to him. Either way, we expect to hear an announcement on the CRC Program in the not too distant future. You can read more information inside on seven new projects approved at the 4 March Board meeting. Eight new project proposals are currently out for review with the members of the APGA RSC committee. I encourage you to review and vote on these. They cover a wide range of topics. I have been completing the final paperwork around the ten papers we are submitted to the APGA/EPRG/ PRCI Joint Technical Meeting to be held in Paris in May. They present a diverse and interesting selection of new research, much of it not previously reported. I think our researchers will do Australian based pipeline research proud when they present the papers. The papers will be available for download from the members’ area of the website in April. Regards, Valerie Page 2 Strengthening a Focus on Gas Policy: A New Name for the Australian Pipeline Industry Association The key industry participant of the Energy Pipelines CRC, the Australian Pipeline Industry Association, has recently changed its name to the Australian Pipelines and Gas Association (APGA). Under its new name, APGA will continue to contribute to gas policy development while also highlighting the value of natural gas to the economy. In a statement released on the 18th March 2015, APGA Chief Executive, Cheryl Cartwright, said, ‘a strong gas sector means a strong gas transmission sector’ and noted that as a representative of gas transportation, APGA had been described as having a unique insight into the whole national gas market. The Energy Pipelines CRC CEO Valerie Linton said that she was looking forward to continuing the close relationship the Energy Pipelines CRC has with the APGA RSC. The APGA RSC members provide invaluable industry support to the CRC’s major research programs. The broadened scope of focus of APGA combined with the expansion of Energy Pipelines CRC research activities into new areas such as offshore pipelines and plastics pipelines will provide new opportunities for research in the years to come. Energy Pipelines CRC CEO Valerie Linton, The Hon. Ian Macfarlane and APGA CE Cheryl Cartwright at the launch of the Australian Pipelines and Gas Association. From the APGA CE APGA has called on governments, in their reviews of the gas market, to also review gas supply. The pipeline industry has been active and proactive in working with government to introduce measures to improve efficiency and transparency of the Australian gas market. The Short Term Trading Markets in Adelaide, Sydney and Brisbane are operating, as is the Declared Wholesale Gas Market in Victoria, providing a balancing mechanism for retail gas. The Bulletin Board provides information about gas flows and pipeline companies have introduced capacity trading facilities. "It's now time for government to focus on what policy changes will assist gas supply and encourage producers to provide gas into the domestic system," APGA Chief Executive Cheryl Cartwright said. Page 3 Visit by Canadian Pipeline Technology Collaborative The Energy Pipelines CRC team recently hosted Mr Richard Wayken, CEO of the Canadian Pipeline Technology Collaborative (CPTC). The goal of Richard’s visit was to investigate effective ways of enhancing collaboration between government, research and industry with the hope of translating this for use in pipeline research and development in Canada. He is investigating the strengths of the Energy Pipelines CRC model as a means to do this. Richard has met with board members, researchers and management staff to see ways in which the CRC model can be implemented or modified for use in the CPTC. Richard Wayken is the CEO of the Canadian Pipeline Technology Collaborative. Richard also spent time meeting with the APGA RSC where he got to see the strong level of industry support and input into the Energy Pipelines CRC’s research programs. Richard Wayken Page 4 Deakin Student on the Moomba to Sydney Gas Pipeline Opportunities for Energy Pipelines CRC researchers are valuable for all involved. They allow for interactions and the establishment of relationships between researchers and industry to enhance collaboration. Deakin University student Ying Huo recently participated in one of these opportunities. Ying was attached to the APA’s 1299 km Moomba to Sydney natural gas pipeline (MSP) maintenance program from 4th to 25th November 2014. Built in 1976, the coal tar coated X65 steel 864 mm diameter pipeline is currently under maintenance. Ying participated in the program as a member of the inspection team. Deakin University Student Ying Huo recently participated in inspection activities on the Moomba Sydney pipeline. Ying learnt a lot from this experience and became a pipeliner in his mind and body (see photo below). In a message sent to his colleagues, Ying described his experience in the Australian outback; I am in the desert now, hoho! The working site at the moment is near Tibooburra … My job involves maintenance work in a 6 member team to assess pipeline conditions using magnetic particle and ultrasonic methods, and then decide whether petrosleeves are needed or not for the pipeline’s maintenance.’ Special thanks are due to Michael Brown, Alan Bryson and other APA Group colleagues for facilitating Ying’s secondment program. A very tired Ying Huo on site in the Australian Outback Page 5 NFPCA team visits SEAGas Pipeline On the 27th February 2015, a team of Deakin University researchers, working with the Energy Pipelines CRC, Mike Tan, Davi Abreu, Fari Mahdavi and Shyama Ranade visited the SEAGas pipeline maintenance program at Mortlake. This involved the HBE field joint coating inspection, and then levering off any disbonded coating prior to abrasive grit blasting. The visit was a beneficial experience to all researchers who are working on pipeline coating research projects at the National Facility for Pipeline Coatings Assessment. Special thanks go to Col Symonds (Pipeline Integrity Specialist / Project Manager SEAGas), Tiffany Ware (Origin Project Manager) and Jamie Storer (APA Group Permit Issuing Officer) and other colleagues on the pipeline maintenance site. Researchers from Deakin University recently visited the SEAGas pipeline maintenance program in Mortlake. Left to Right: Shyama Ranade, Davi Abreu, Mike Tan and Fari Mahdavi Page 6 Update on the Pipeline Research Council International The Pipeline Research Council International (PRCI) is a member of a tripartite agreement which also includes the European Pipeline Research Group and the Australian Pipelines and Gas Association. A new edition of its newsletter Throughput will be available next month. In the meantime, an update on its activities can be found below. Upcoming Joint Technical Meeting on Pipeline Research: The Pipeline Research Council International (PRCI) is a member of a tripartite agreement which also includes the European Pipeline Research Group and the Australian Pipelines and Gas Association. The PRCI will be part of the upcoming Joint Technical Meeting on pipeline research which also includes the European Pipeline Research Group, the Australian Pipelines and Gas Association and the Energy Pipelines CRC. The event will be held in Paris, France from the 3rd - 8th May 2015. Project Updates: PRCI is nearing completion on a number of projects including; CRA weld overlay pipes for subsea application. Research has been completed on this project to examine the key issues in the manufacture and testing of full length weld overlay pipe. The research also included fatigue performance of this pipe with different surface conditions through full scale resonance fatigue testing. The objectives were to determine the effect of pipe length on manufacturability, consider NDE alternatives for CRA pipe and evaluate fatigue performance. Mechanical seal auxiliary system guideline. The objective of this project was to provide an additional resource for the selection, maintenance, and operation of seal auxiliary systems. This project collected input from end-users surveys on current practices relating to seal auxiliary systems, on interviews with seal vendors, and a review of current standards and available technologies. Determine the requirements for existing systems to transport ethanol without cracking. A project consisting of two phases was performed to address the program objectives. Phase 1: In the first phase, screening tests were conducted to identify ethanol blends that are unlikely to cause internal stress corrosion cracking (SCC). A literature survey and laboratory testing also were performed to evaluate static and dynamic elastomeric seals. Phase 2: In the second phase, crack growth tests under static and cyclic loads were conducted in ethanol/blends that caused cracking in slow strain rate tests to identify safe operating and or batching practices that prevent the initiation and growth of SCC. More information on these projects can be found at www.prci.org The day was well attended with over 60 attendees from various companies and research groups. Page 7 Researcher Profile: Ajit Godbole Ajit Godbole is currently a Senior Research Fellow in the School of Mechanical, Mechatronics and Materials Engineering at the University of Wollongong, Australia. Ajit was educated at IIT Bombay, India, University of Tennessee, Knoxville, USA, and University of Wollongong, Australia. He has more than 30 years’ experience in university-level teaching and research, besides a 4 year experience as research engineer (CFD) in France and India. Ajit’s research interests include fluid dynamics, heat transfer, thermodynamics and the interrelationships between these fields. Ajit Godbole is currently a Senior Research Fellow in the School of Mechanical, Mechatronics and Materials Engineering at the University of Wollongong, Australia Under the Energy Pipelines CRC banner, Ajit has been carrying out research on heat transfer effects in pipeline processes. Broadly these effects can be classified according to the fluid velocity scales involved in the process – from the gentle natural convection flows of water generated during hydrostatic tests to the sonic/supersonic gas flows during blowdowns. It is interesting that the pipeline industry asks virtually the same question in either case: how does the pipe wall temperature compare with the fluid temperature? The answer to this question can affect the conclusion (leak/no leak) about a hydrostatic test, or lead to over-conservative specifications of pipe material properties. Related Energy Pipelines CRC projects have been ‘Hydrostatic Test Temperature Measurement Uncertainty’ and ‘Low Temperature Excursions during Pipeline Decompression’. Ajit’s research has involved a blend of CFD simulations, mathematical and scale analyses, and successful validation via laboratory-scale and field experiments. Ajit has interacted with other members of the Energy Pipelines CRC research team to broaden his knowledge base to include research on pipeline fracture and atmospheric dispersion of CO2 in the event of a CO2 pipeline rupture. Ajit will also be involved in a multi-faceted study of the risks associated with gas pipeline blowdowns. Among his very serious hobbies are drawing and painting and Indian classical music. Ajit Godbole Page 8 Research Update: New Projects Approved Earlier this month the Energy Pipelines CRC Board approved seven new research projects, which brings the total number of active projects across the four research programs to 35. A short summary for each of these new research projects is provided below. Even though we have got a number of new research proposals under development (in fact 8 new proposals were sent to the APGA RSC last week for evaluation) I would like to encourage industry to continue to submit new research ideas. Klaas van Alphen outlines details on recently approved Energy Pipelines CRC Research Projects. Research Proposal – RP2-12: Cathodic shielding and corrosion under disbonded coatings Surface coating and cathodic protection (CP) are the most widely used methods for protecting buried steel pipelines from corrosion in the energy pipeline industry. Unfortunately under practical pipeline conditions, coatings and CP can work against each other due to natural phenomena such as cathodic disbondment and cathodic shielding. Cathodic disbondment is the loss of adhesion between a coating and its metal substrate due to CP-induced chemical reactions. Cathodic shielding is the shielding of CP currents from reaching a steel surface by disbonded coatings or other high electrical resistive objects. Cathodic shielding is widely believed to cause corrosion under disbonded coatings; however the actual effects of cathodic shielding on corrosion have not been sufficiently quantified, primarily due to technical difficulties in measuring corrosion and CP efficiency under a disbonded coating layer. This project is designed to quantify the effects of cathodic shielding on pipeline corrosion by means of innovative research methodologies. Results from this research will assist pipeline and coating industries in the determination of CP and coating compatibility, in the development of next generation of pipeline coatings, in the selection and adjustment of CP operational parameters, and in the improvement of maintenance strategies. Research Proposal – RP2-13: Predicting pipeline failure through corrosion modelling This research project is part of a comprehensive R&D effort directed at improving asset management tools available to the pipeline industry. It is designed to contribute to a pipeline condition monitoring (PCM) system that is currently under development at Deakin University for predicting and preventing failure of non-piggable and high risk pipeline sections where CP failure, coating disbondment and degradation, localised corrosion and stress corrosion cracking (SCC) could occur (see research proposal RP2-14 below). The objective of this project is to develop a deterministic model for predicting pipeline failure. The model will be built based on computational simulation and analysis of data acquired from in-situ pipeline condition monitoring sensors developed as part of proposed project RP2-14 and predictor features related to CP failure, coating disbondment and degradation, localised corrosion and SCC. This project will in turn inform the development of a ‘decision support framework for pipeline integrity management’ as proposed under project RP2-15. The outcomes of this project will assist pipeline owners to prioritise site survey and inspection operations and to develop maintenance strategies. The day was well attended with over 60 attendees from various companies and research groups. Page 9 Research Update: New Projects Approved Klaas van Alphen outlines details on recently approved Energy Pipelines CRC Research Projects. Research Proposal – RP2-14: A pipeline corrosion and coating failure early warning system This project aims to develop, evaluate and practically apply a Pipeline Condition Monitoring (PCM) system by installing suitably designed sensors on semi-field testing pipeline and on real life energy pipeline sections, in particular, on strategic and ‘worstcase scenario’ pipeline sections between cathodic protection units (CPUs), nonpiggable pipeline and other high risk pipeline sites. The PCM system will be evaluated and applied to provide real-time monitoring and early warning of site specific CP loss, coating disbondment and degradation, and localised corrosion. This PCM system will be designed based upon the application and integration of research findings and outcomes from past and current Energy Pipelines CRC projects such as the pipeline condition monitoring sensors including localised corrosion and coating failure sensors developed in projects RP2-07C and RP2-11. This PCM system will be designed based upon the application and integration of research findings and outcomes from past and current EPCRC projects such as the pipeline condition monitoring sensors including localised corrosion and coating failure sensors developed in projects RP2-07C and RP2-11. This research is part of the Energy Pipelines CRC’s comprehensive R&D exercise directed at improving the asset management tools available to the pipeline industry. It is expected to develop a technology ready for industry applications. Research Proposal – RP2-15: Prediction-based decision support framework for energy pipeline integrity management This project targets the cost of integrity management for existing pipelines and capitalises on the introduction of integrity management (information) systems. It seeks to provide decision support tools for the integrity engineer and asset manager. The tools provided will allow data-enabled business-driven decisions informed by whole of life costs to determine the actions required to maintain acceptable pipeline integrity. The decision support system will result in the integration of all decisions typically made by owners to retain acceptable integrity: e.g. when to deploy ILI against continued direct assessment and repair; when to undertake coating refurbishment against the deployment of additional CP units, zinc or continuous anodes. An advanced decision support framework will be devised with the capability of being integrated with any organisation’s integrity management tool, such as DNV Uptime, once it is coded into commercial software. Page 10 Research Update: New Projects Approved Klaas van Alphen outlines details on recently approved Energy Pipelines CRC Research Projects. Research Proposal – RP2-09C: Manufacturing processes for SCC resistance Stress corrosion cracking (SCC) has been known to affect gas pipelines since the 1960’s, and in the extreme can cause a pipeline rupture. Although much work has been devoted to understanding how SCC develops and grows, it is very difficult to predict a pipe’s SCC susceptibility from its microstructure or its manufacturing history. There is the commonly held perception that modern pipes are more resistant to SCC, but this can also be due to the improved external coatings used for pipelines and not just modern steel chemistry and manufacturing processes. This project aims to relate manufacturing processes to microstructures with a lower SCC susceptibility in a quantifiable manner, such that it will be possible to determine if modern pipes can offer increased SCC resistance if the coating fails. As a secondary aim, this quantification will allow asset owners to determine the relative SCC resistance of existing pipes based on the manufacturing records/ microstructure. A tertiary aim is to provide pipe manufacturers with knowledge as to what manufacturing process have been shown to reduce SCC susceptibility in the pipes. Research Proposal – RP3-10: Emerging energy sources and their transportation The project is about quantifying the opportunities for pipelines that carry alternative energy fluids and natural gas / alternative fluid blends in the next decade in Australia. It will assess the economics of specific scenarios with realistic plant and pipeline locations, scales and costs, and perform sensitivity studies. Once the compositions, properties, and pipeline operating conditions of the most likely fluids are quantified, a gap analysis will identify gaps in knowledge, and research needs related to pipeline design, operation, construction, safety and environment, for the most likely pipeline fluids. Research Proposal – RP6.3-09: Concrete mattress design guideline The proposal is to develop a guideline for the design of concrete mattresses for stabilising pipelines, which will benefit the future of both offshore and onshore pipeline operators. The guideline will include such design considerations as selfstability, secondary stabilisation of pipelines, scour prevention, and external impact protection. The guideline will improve the level of knowledge that is available within the industry and subsequently will serve to improve overall pipeline safety. Page 11 Energy Pipelines CRC Projects RP1– More Efficient Use of Materials for Energy Pipelines RP1-01 overarching– Online Quality Assurance for Pipe Girth Welding RP1-01A– Girth Welding– Review of NDE Options– Completed RP1-01B - Online Monitoring System Specification and Design - Completed RP1-02 overarching - Formation Mechanism of WMHACC RP1-02A - Effect of Restraint on WMHACC - Completed RP1-02B - Effect of Microstructure on WMHACC - Terminated RP1-02C - Safe Envelope Modelling for Prevention of WMHACC -Terminated RP1-02D - Effect of Consumable Chemistry on WMHACC - Terminated RP1-02E - Effect of plastic strain on WMHACC - Terminated RP1-03 - High Strength Pipeline Steels - In Progress RP1-04A - WMHACC Scoping Study– In Progress. RP6.1-01 - Effect of Ti and N on Heat Affected Zone Toughness -Completed RP6.1-01B - Effect of Ti and N on Heat Affected Zone Toughness - In Progress RP6.1-02 - Industry Specification for Linepipe - In Progress RP6.1-03 - AS2885.1 Toughness Review - Completed RP6.1-04 - Pipe Size Effect in DWTT - Completed RP6.1-05 - Review of mechanised GMA girth welding of pipelines-Completed RP2– Extension of Safe Operating Life of New and Existing Pipelines RP2-01 - Benchmarking Australian Pipeline SCC - Completed RP2-02 - Coatings to Minimise Corrosion - Completed RP2-03 - Cathodic Protection of Line pipe - Completed RP2-04 - Life Prediction and Asset Management - Completed RP2-05 - Tomography of Inclined Stress Corrosion Cracking - Completed RP6.2-01 - Lightning Damage of Energy Pipelines - In Progress RP6.2-02 - Understanding SCC Initiation on Gas Pipelines - In Progress RP2-06 overarching—Coatings RP2-06A - Coatings Facility - Phase 1 - Completed RP2-06B - Coatings Durability - Completed RP2-06C - Coatings Facility - Phase 2 - Completed RP2-06D - Coatings Facility - Phase 3 - In Progress List of all Energy Pipelines CRC research projects and indication of status 15 March 2015 RP2-11 - Coating Cracking and Disbondment - In Progress RP2-12 - Cathodic Shielding under Disbonded Coating– In Progress RP2-07 overarching—Life Prediction and Asset Management RP2-07A - Benchmarking Pipeline Corrosion for Life Prediction - Completed RP2-07B - Computational Life Prediction – Terminated RP2-07C - Pipeline Health Monitoring and Life Prediction - In Progress RP2-07D– Pipeline Operational Life Prediction by Neural Networks– In Progress RP2-13 - Predicting Pipeline Failure through Corrosion Modelling– In Progress RP2-14 - Pipeline Condition Monitoring Sensors– In Progress RP2-15 - Decision Support for Pipeline Integrity Management – In Progress RP2-08 overarching—Improved Cathodic Protection for Linepipe RP2-08A - Transient Loss of Cathodic Protection - Completed RP2-08B - Transient Loss of Cathodic Protection - Phase 2 - In Progress RP2-09 overarching—Model of Australian SCC Crack Growth Rates RP2-09A - Mechanics of Inclined SCC - In Progress RP2-09B - Interaction of Inclined SCC Cracks - In Progress RP2-09C - Manufacturing Processes for SCC Resistance– In Progress Page 12 Energy Pipelines CRC Projects RP3– Advanced Design and Construction of Energy Pipelines RP3-02 overarching– (10-04)- PhD Student and Postdoc Program RP3-02A - (10-05) Modelling of Decompression Waves - Completed RP3-02B - (10-06) Pressure and Thermal Transients - Scoping Study - Completed RP3-02C - Fracture Simulation for Gas Pipelines - Completed RP3-02D - Measurement Uncertainty in Hydrostatic Leak Tests— Completed RP3-02E - Decompression Velocities in Rich Gas Mixtures - Completed RP3-02F - Coupled Model for Fracture Propagation - Completed RP3-02G - Pressure and Thermal Transients - Phase 2 - Completed RP3-02H - Hydro Test Uncertainty - Phase III - Completed RP3-02I - Fracture control software: Phase III - Completed RP3-02J - Fracture simulation for gas pipelines - Phase II - In Progress RP3-04 overarching– UOA PhD Student and Postdoc Program RP3-04A - Future Energy Media - Completed RP3-04B - Future Energy Fluids - Phase 2 - In Progress This is a listing of all Energy Pipelines CRC projects within the four main research programs. There are also a series of projects funded by DRET (now Department of Industry) on carbon dioxide pipelines. RP3-03 - Corrosion by New Energy Fluids - Completed RP3-05 - GRE Pipeline Research - Completed RP3-06 - Assessments of Solar Fuels in Australia - Completed RP3-07 - Construction strain demand on coatings - In Progress RP3-08 - Decompression of a dense-phase fluid - In Progress RP6.3-01 - Geotechnical Guidelines - Completed RP6.3-02 - Fugitive Emissions - Completed RP6.3-03 - PipeStrain - Completed RP6.3-04 - Pipeline Uprating - Completed RP6.3-05– Shore and Water Crossings Guideline– In Progress RP6.3-06– Fluid Structure Interaction Modelling– In Progress RP6.3-07– Pipeline Damage Caused By Drilling Equipment In Progress RP6.3-08 - Weeds Management– In Progress RP6.3-09 - Concrete Mattress Design Guideline– In Progress RP4– Public Safety and Security of Supply of Energy Pipelines RP4-01 - Safety Incentive Schemes - Completed RP4-02B - Safety in Design - In Progress RP4-02C - Sociology of Safety - Completed RP4-03 - Organisational Design-In Progress RP4-04 - Land Use Planning - Completed RP4-06 - Industry Seminars - In Progress RP4-07 - Urban Planning around Pipelines - Transferred RP4-08 - Understanding Pipeline Awareness—Transferred RP4-09 - Regulatory Effectiveness - In Progress RP4-10 - Understanding ALARP - Transferred RP4-11 - Incident Reporting– Transferred RP6.4-01 - AS2885 Safety Management Study Benchmarking - Completed RP6.4-02 - Sociological Analysis of San Bruno - Completed RP6.4-03 - Intergenerational Studies - Completed RP4-20A - Third Party Risks to Pipelines– In Progress RP7– DRET CO2 Pipeline Research RP7.0 - Draft CO2 Appendix for AS2885 - Completed RP7.2.1 - Equations of State to Model the Behaviour of CO2 Mixtures - Completed RP7.2.2 - Decompression Characteristics of CO2 Mixtures - Completed RP7.2.3 - CO2 Dispersion - Completed RP7.2.4 - Water Content in CO2 Mixtures - Completed RP7.3 - Cost-Benefit Modelling for CO2 Pipelines - Completed RP7.4 - Public Safety, Community Consultation and Organisational Requirements for CO2 Pipelines - Completed Page 13 Overview of the Energy Pipelines CRC Enabling safer, more efficient and reliable pipelines to meet Australia’s growing energy needs CHECK US OUT ON THE WEB: www.epcrc.com.au MORE INFORMATION: Valerie Linton CEO Energy Pipelines CRC The Energy Pipelines CRC is a collaboration between the members of the APGA Research and Standards Committee and researchers at the Universities of Adelaide and Wollongong, Deakin University and RMIT University. The CRC is supported by a $17.5m grant over 10 years from the Commonwealth Government and $1m per annum cash and significant inkind contributions from the RSC members and the Universities. The aim of the Energy Pipelines CRC is to deliver technology to the pipeline industry that will extend the life of existing gas pipelines and will help build the next generation of gas and other energy fluid pipelines. The research work of the Energy Pipelines CRC is divided into four programs, which are: More efficient use of materials for energy pipelines, Extension of safe operating life of new and existing energy pipelines, Advanced design and construction of energy pipelines, and Public safety and security of supply of energy pipelines. University of Wollongong Faculty of Engineering Phone: 02 4298 1546 Mobile: 0407 331129 E-mail: [email protected] Business Manager: Robert Newton Phone: 02 4252 8950 E-mail: [email protected] Communications Officer Matthew Byers Phone: 02 4239 2361 E-mail: [email protected] Research and Innovation Manager Klaas van Alphen Phone: 02 4221 3667 Email: [email protected] Education Officer Lyndal Worsfold Email: [email protected] Upcoming Events PRCI/EPRG/APIA Joint Technical Meeting. Paris, 3rd May– 8th May 2015. Energy Pipelines CRC Board Meeting. Wollongong, 9th June 2015. 11th Energy Pipelines CRC/ APGA RSC Research Seminar. Wollongong, 10th June 2015. Energy Pipelines CRC Research Quality Review Wollongong, 9-11th June 2015. 61st APGA RSC Meeting. Wollongong, 11th June 2015. 6th Energy Pipelines CRC Researcher Conference Deakin Waurn Ponds Campus, Geelong, 29th– 30th June 2015.

© Copyright 2026