Innovation Roadmap â Life Prediction and Asset Management

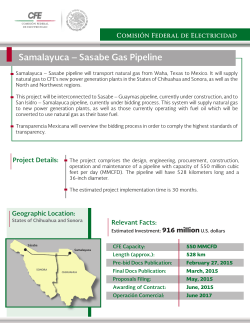

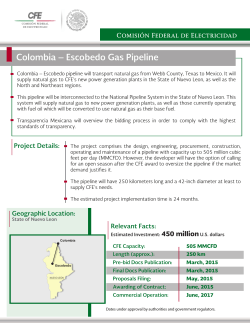

Energy Pipelines CRC – Innovation Roadmap – Life Prediction and Asset Management Match research outcomes with future requirements Research Activities Life prediction and asset management Increase understanding of requirements Develop a solution RP2-07A: Review of asset management tools used in industry today RP2-15: Decision support system for pipeline asset management RP2-07D: Neural network model for pipeline degradation prediction RP2-04: Identification of key parameters in predictive deterioration models RP2-XX: Benchmarking integrity management related risks Pipeline condition monitoring RP2-11: Understand mechanisms of coating cracking and disbondment RP2-13: deterministic model to predict CP / Coating failure / localised corrosion RP2-07C: Prototype in-situ monitoring tool developed to detect localised corrosion under disbanded coatings Knowledge Developed *Review of asset management tools / decision models used by pipeline industry *Review of existing and new pipeline health monitoring tools available in the world market RP2-XX: Improved interpretation of ILI data Needs / Requirements Improved asset management software developed and industry training provided Improved life prediction models and asset management systems New pipeline condition monitoring sensors manufactured / available to industry Improved pipeline conditioning monitoring tools / sensors RP2-14: Pipeline condition monitoring sensors tested in real life pipeline applications IP Developed *Algorithms and a system for pipeline degradation prediction utilising neural networks *Decision support system for pipeline asset management *Pipeline condition monitoring system that can detect localised corrosion under disbonded coatings and under ineffective CP conditions Identify, record and utilise/commercialise IP © Energy Pipelines CRC 2015 Implement solution Utilisation of IP *Manufacturing/sell of pipeline monitoring sensors + associated software and services *Asset Management Decision Support software released The first strand of research concentrates on improved asset management/decision support systems (RP2-15). Central to this system is the development of a life prediction tool (RP2-07D ‘Pipeline Operational Life Prediction by Neural Networks’). This work should provide the decision support tools giving pipeline operators/owners the capability to conduct option analysis to determine lowest NPV cost while retaining integrity. This will be informed by the capability to identify confidence limits on life prediction: the time until significant repair or de-rating of the pipeline is required and the associated risk levels. The other strand of research will complement/inform the development this asset management tool by building phenomenon-based degradation models based on experimental as well as field survey data (RP2 07C ‘Pipeline Health Monitoring and Life Prediction’) to better inform the life prediction tool developed under RP2-07D. The primary aim of this work, however, is to develop a pipeline condition monitoring (PCM) system by installing suitably designed sensors on real life energy pipeline sections, in particular, strategic and ‘worst-case scenario’ pipeline sections between cathodic protection units (CPUs), non-piggable pipeline and other high risk pipeline sites (RP2-13/RP2-14). The PCM system will provide real-time monitoring and early warning of site specific localised corrosion, cathodic protection (CP) loss, coating disbondment and degradation. © Energy Pipelines CRC 2015

© Copyright 2026