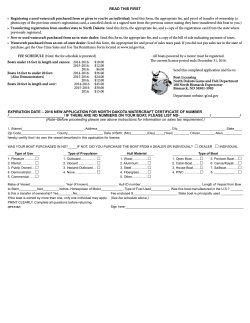

How To Make Sure The ou’re Used Sailboat Y Thinking About Buying is