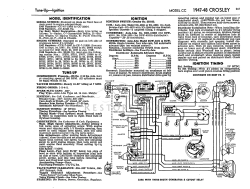

Ignition System Components and Operation