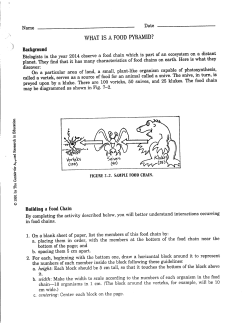

UK wheat to bread supply chain