Blast Pipe 2015 6 - Hutt Valley Model Engineering Society

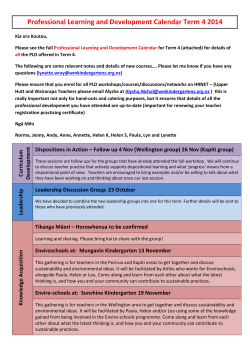

Blast Pipe July 2015 From the — HUTT VALLEY MODEL ENGINEERING ! ! ! ! SOCIETY INC. 6 Marine Parade, Petone, Lower Hutt 5012, New Zealand Email address - [email protected] Website - http://hvmes.com Patron - Ian Welch (Mainline Steam Trust) President - Claude Poulsen Ph 568-8507 [email protected] Secretary - Gavin McCabe Ph 567-4487 Treasurer - Chris Gousmett Ph 526- 3705 Editor - Peter Anderson Ph 232-4533 [email protected] and the MAIDSTONE MODEL ENGINEERING SOCIETY INC c/o 95 Holdsworth Av, Trentham, Upper Hutt 5018 President - Nathan Reynolds Secretary - Bob Begbie Ph 976-9114 [email protected] Treasurer - Brian Hawke Ph 528-4938 Patron - His Worship Mayor Wayne Guppy. Location - Maidstone Park, Upper Hutt Blast Pipe is printed with one or two pictures in colour. A Pdf colour version is available on the website (per courtesy Charlie Lear) or e-mailed direct to members on request. Webmaster - Peter Targett Notice of Meetings Hutt Valley MES Meeting on the first Wednesday, 1 July 2015 at the clubrooms, Petone at 7-45pm. the usual ‘Bits & Pieces’ session. Hutt Valley MES Committee On the third Tuesday, 21 July at 7-30pm NB -- Visit to The Printing Museum 54 Flux Rd Mangaroa 1300hrs Monday 20 July Maidstone MES The next meeting will be Thursday 9 July at 7.30pm Maidstone Park, Upper Hutt Maidstone MES Notes - Bob Begbie We wish the best to our members, to members at HVMES, to members at Maidstone MES, UK and to our readers. We got better weather this month than that which forced cancellation of our regular monthly meeting and our Annual General Meeting in May. We held the AGM, together with our next regularly scheduled meeting on 14th June. We completed all matters required in our AGM schedule in that evening. In his statement to members our president, Nathan, expressed real satisfaction at the progress made by the society in the year just past. He Peter Moyes fathoming out some of the features of the sectioned Ross Pop safety valve at the end of the formal part of our meeting. The item was loaned by the Silver Stream Railway Society Inc. Photo - Anderson thanked members for, and congratulated them particularly, on the progress made in development of our facilities and refinement of operating procedures. He sees our next important goal as that of attracting and training new members to better utilise the work we have done. Minutes of that meeting will be posted on boards in our meeting room and in our station building. In a short June monthly meeting which followed the AGM we considered what we might best do to develop our club further and particularly to attract additional members. With regard to our operating equipment we decided to build a further two 7½” gauge passenger wagons, preferably to the wood framed design developed in British Columbia, Canada. We already have two wagon sets of 7½” G bogies in reserve for that job. A “Men’s Shed” male hobbies workshop has been started and is being further developed in Upper Hutt, already with, I believe, good quality woodworking machinery. That may provide an opportunity for us to do some of the work that is needed and to meet local hobbies enthusiasts who may be prepared to join or to assist with our railway operations. We also considered, as a longer term project, the possible extension of our railway in a loop down toward Park Street and shifting the passenger loading and unloading station nearby the children’s playground. That will be a large and important project for our society. Ross Hardie showed another of his tricky pieces of woodwork, a set of three pieces of 3ply, or similar, each about 2” square with seven vee teeth about 3/16”deep on each side of the square and mounted, each square on a *2* central spindle (nail or tack). The other two pieces could be driven and rotated by turning the one squared driver that was fitted with a turning handle. I am sure most of us had not seen an arrangement like that before. We managed to run our railway on the first Sunday, 7th June. We met new customers and achieved a good rides tally. We hope for similar success on our next running day, 21st June. Activities we have scheduled for July include:Railway running days, 1.0 to 4.0 pm each day, weather permitting. Sunday 5th July, Team 1 Sunday 19th July Team 2 Our society July Meeting will be held from 7.30 pm on Thursday 9th July, in our meeting room in the amenities block in Maidstone Park. We will appreciate your company. Hutt Valley MES Notes - Editor The June meeting included our Annual General Meeting and our President presented his report as follows 55th. Annual Report Hutt Valley Model Engineering Soc. Inc. Members, Well here we are, in our 55th. Year, and gong stronger than ever. This can only be attributed to the support of, you the members, and the guiding work of your Committee. What we have achieved this year may not be very apparent. However, with the assistance of paid help, major repairs to the buildings outer fabric have been done. This included the installation of a new, and more user friendly, main door. All the window grills have been removed, galvanised, and replaced and already improve the outer appearance. Rusting nails have also had attention so that the building is now ready for a repaint. A bothersome but necessary need in the exposed position we occupy. At this stage tentative ways of improving the inside décor have been discussed. The outside must be finished first. The square gear demonstration model shown by Ross Hardie at the MMES meeting. The intermediate gear would have a changing angular velocity but the final gear would match the drive gear. Anyone got a use for it? ! ! ! ! ! Photo - Brian Hawke. Again I believe we have had a series of fruitful evening meetings. To all those who contribute my sincere thanks. It is, you the members, who make the evenings. To those who run our rail system, from which the public get great pleasure, a very big thank you. Without this facility we would not be able to maintain and operate the Club. Which brings me to point my finger at those of you, not necessarily interested in trains, you can, and I repeat can, help run the system. Do not leave it all to a small group. Nuff said. On a somewhat sour note I must report that we have some sticky fingers in the Club. Not nice but items have gone missing and money from the “Honesty Box’ most certainly has. Should we, your Committee, find the one responsible he will be out of this Club so quickly he will not know what hit him. BE ASSURED. Back to more pleasant matters. To the Committee I tender my great respect. You have worked hard this year in overseeing the building repair work as well as maintaining the worthiness of our rail stock. On behalf of the members, well done. I do not propose to single out individuals, but, having said that I must. First to Gavin McCabe for the wise guidance he gives on many matters and to Peter Anderson for the work he does in producing our, always interesting Maggie and the Case TE pass during the fine afternoon run on Sunday 14 June. The sawmill did not get into operation as there were plenty of passengers available, and David wanted a change anyway. ! Photo - Anderson *3* newsletter. I think at this point a round of applause would be appropriate. Finally to all our members I wish a successful year in whatever project you are undertaking Claude N. Poulsen President. The Case was set up as usual in the centre of the track on June 14. Claude is conferring with David and David G-T handles Hercules up the hill in the background. Wellington in the far distance. Photo - Anderson Chris Gousmett discusses with Ian some feature of the new design of heat exchanger under construction for one of his Briggs boilers. David Turner and Peter Moyes in the background. ! ! ! ! Photo - Anderson The Treasurer’s report was presented also and was accepted by the meeting subject to a satisfactory report from our reviewer. Claude had a show of hands to give an indication of who would be able to pay a visit to the Printing Museum at Mangaroa. It is not available to the public as it is in temporary premises since its shift from the Silverstream site. A group of us will visit on Monday 20 July as notified in our Meeting notice. Get there via Mangaroa Hill Road from Upper Hutt We then got on with the bits and pieces report followed by David GrantTaylor explaining how the Ross Pop safety valve functions on the full size locos. Ian Welch started off the discussion on Brigg’s boilers as built and fitted into most of Harold Sinclair’s locomotives. They work well for several seasons and then the heat exchanger portion in the firebox area clogs up and cannot be easily cleaned out. Construction is difficult too, as it is hard to get good brazed joints on the multiple tubes between the headers. He has one of these being replaced at the moment with a unit built out of Duplex stainless more in the form of the typical loco boiler with water legs surrounding the firebox. The drawings for the unit were prepared by Peter Gibbs and the component parts were on the table tacked together ready for a certified welder to finish the job. It will be provided with inspection plugs to help in washout maintenance. Water circulation will still be from the pipe connections at the bottom at the tube plate end, and from the top corners at the firehole end. Ian went on to tell us a bit about his recent rail tour in the UK. Some of the gloss had been taken off it by the train being diesel hauled instead of the promised steam. This happened as a result of another steam hauled special running a red light and a precautionary ban on steam had been put in place. He referred to the Stapleford 10½” G Railway and to the full size P2 Being built by the Darlington Locomotive Works. The P2 is an impressive 2-8-2 fitted Peter and John wait for pressure to build on the Simplex, Maggie. Blast Pipe July 2015 *4* with Lenz Valve gear and is named Prince of Wales. (the same firm was responsible for the building of Tornado, the A1 4-6-2) Peter Targett then told us that Doug Chambers is underway with the building of the Dart boiler using the components he has provided. (Noted in the June Generator from Palmerston North that Doug had some bits at their meeting on 28 May) Peter went on to describe how he produced a nicely domed smokebox door by turning it up from an aluminium blank rather than forming it out of sheet material. The special tool mount used produced the comparatively large radius domed front on the door. “If the ally is not up to the job I’ll make another one” Peter asserted in his confident manner. David then got going on on the safety valve topic and with the help of some diagrams on the board showed the features of the seat, the additional diameter containing the “huddle chamber” and some of the other features of the sectionalised safety valve kindly made available by Silver Stream Railway Soc Inc. The objectives to be met in the design included the rate of discharge, reliable operation, secure adjustment, low leakage, quick opening and closing, with a set differential of usually 5%. There was a part of the sectioned valve that we could not work out and it is the chamber formed by a screwed ring by Peter Moye’s thumb in the photo but the light may dawn one day. (Suitable safety vales for our locos is another matter and there is plenty of information on the web regarding them with some folk advocating ‘soft pop valves’.) A followup on our President’s report -WILLIAM TAYLOR. As of Sunday 21st June 2015, William Taylor is expelled from the HVME Society. This was found necessary following him being observed committing serious misconduct. He has been presented with a copy of the relevant motions passed in committee and a trespass notice. This trespass notice applies to our Club Rooms and Station building. It is likely that a trespass notice may be served on him, by the Hutt City Council, covering the grounds area. phone call. We've now caught up regularly since then. John was keen to try out one of the locos and last Sunday was a perfect day for it.” David Turner had his Case in action again too and there are some photos to cover the run that day. Back to the 7 June, when Roy was in charge, we were joined by Jon Mason from Palmerston North in his roll as a MEANZ Safety Auditor. I represented the club and managed to show him most of the detail he required. There were some items that need to be dealt with, and these are being attended to by the committee, and the process of registration will be worked through as a result. Wheel Castings Peter Moyes has been looking for some for the Asia loco he has under construction and tried a Palmerston North firm but they were not accepting outside jobs now. He was referred to ‘Casting Shop Ltd.’ Sockburn, Christchurch and made contact with an Ian Close of the firm and has been given assurance it can be done at a price that would be reasonable in the light of importing costs from the UK. Their cast iron is of a good quality and imported from China. The present plan is that Murray McKenzie will be making the required pattern for the casting process. An Interesting Washer Factoid For quite a while I have been trying to find the name of an old style lock washer, and as near as I could tell no one else knew the answer anyway. Eventually I found the answer in the 1934 Brittanica. It is a Thackray washer. And the name for the more common lock washer is a Grover washer. Now you have it !! - D.G-T. Claude N. Poulsen. Club President. At the Track There have been some good run days this last month when the weather had looked doubtful but recovered for our benefit. On Sunday 21 though we cancelled ahead of time due to our own internal workings! On Sunday June 14 there was some extra activity in that Peter Targett had his Maggie out for a run with a friend John. Peter reports -- “We joined the RAF together in 1966 and until recently the last time we'd seen each other was in 1969 when we marched off a parade square at the end of our training. After all that time we find ourselves on the other side of the world and living locally. Another colleague from those times mentioned John had come to NZ in the 70's, it took just 2 mins to find him in the white pages and a John gets his turn at Maggie’s throttle on Sunday June 14 under Pete’s watchful eye. Hercules with another load of passengers in the background.! ! ! Photo - Anderson *5* An Interesting Boiler Factoid. Schmidt or the Brotan system, as in the two bottom pics, but none exactly the same as the Briggs boiler which has a horizontal plate at the firebox top, and only has watertubes for the sides of the firebox. And the top header in the Briggs must reduce the circulation a great deal. But it would be a great deal easier to replace the watertube unit than to deal with the drum in the Brotan system. Many of us know of the BELPAIRE firebox with the almost rectangular cross section of the shell at the top of the firebox, Presumably this is to increase the steam space. The other sort of boiler with the round top is known as the CRAMPTON boiler. -- which leads us onto -- Locomotive Boilers with Peculiar Fireboxes. - David Grant-Taylor At our meeting of 3 June we heard Ian talk of his Briggs boiler and someone asked if there were any full sized Loco’s with that style of boiler. I have collected a few samples, but I list only those with boilers which couple a “watertube firebox” with a more conventional firetube barrel. If you want a real surprise at how fertile, and generally futile the human mind is in developing extremely complex systems visit the website Douglasself.com and plunge into some really odd stuff. Follow the thread Unusual Steam Locomotives on the right top of his web home page. CPR 8000 2-10-4 multi pressure boiler Picture (top) taken from gizmodo.com, Baldwin 6000 image from Douglas self.com (middle) Of course, there are a lot more, most based on either the SteamRail Wanganui Some photos of the recent flood have come through with some comment from their President, Blair Jordan. This is a full size rail group but we still feel for them. “After many years of SteamRail Wanganui missing the floods we have been hit along with the KiwiRail yard. It was Wanganui's worst flood on record. This will take several weeks to clear up. Before we can even start in the shed we will have to clear the doorways and tracks in front. This will allow us to get the Locos and rolling stock out so we can do the big job of getting rid of the mud from inside.” Their locos are small diesels rather than steam but they are a growing organisation and steam trips from other groups do call by. Plenty of muddy sediment left in the SteamRail shed. The water level shows just above the Tr axle centre. Blast Pipe July 2015 *6* John Romanes’ Latest Locomotive. This report is from the Winter issue of the Keirunga Park PlatformRecently completed and running very smoothly is the SNCF15020 Built by John Romanes, this is his 20th engine built in the last 40 odd years — a tremendous effort!! Many of his engines are to be seen at NZ tracks. “This loco is the 20th and last locomotive that I have built. As usual there is something a bit different about it. In general it is a standard battery electric, driven by four 450watt 24v dc geared motors via a 4QD controller. Four 12v 120amp/hr batteries with a 24v, controlled charger mounted on board. So what’s different?? Both of the two axle bogies have ‘Electric Differentials’. No more wheel slip or loss of power in the curves. Each axle is fixed into the axle-boxes and the wheels, complete with sprockets welded onto the wheel, are fitted with bearings that allow them to run free on the axle. Mounted at each end of the bogie is a motor/ gear- box which drives the furthest away wheel, onto which is mounted a triplex sprocket. From this sprocket a return chain drives the wheel closest to the motor. Note; the triplex sprocket allows two chains to run on the outer teeth with ample clearance between them. (the centre sprocket teeth are not used.) The opposite side of the bogie is a mirror image, so that each drive is independent of each other. The only common factor is the 24v power supply. When the loco enters a curve the inside motor and wheels come under a little more load and slow down whilst the outside motor and wheels are relieved and speed up. With the controller in a fixed position there is no change in speed no matter how tight the curve is. The finished loco has scale suspension and after a few hours running, to free up the tight spots, performs brilliantly and provides a very stable unit. Apart from a few extra components such as scale horns, couplings etc the loco is finished and I am reasonably happy with it. I have run the loco on a number of running days and it exceeded all of my expectations. With two sit - a - stride passenger cars (Giles type with bearings in the wheels) I am able to set the controller at the start of the trestle bridge and it runs the complete track without any speed variance at all. It seems to be a winning system.” John Romanes Data - SNCF BB15000 7¼”G Locomotive Length — 2.184mtrs. (86 inches) Width — 381mm (15 inches) Height — 450mm (17.75 inches) Centre to Centre Wheels in Bogies — 381mm (15”) = 40 x 0.375 inch chain links. Wheel Dia. — 150mm Motors — 4x450 watt 24v DC = 1800 watts Motor RPM — 550 Wheel speed @ 12kph — 426rpm = Drive Sprocket — 19 tooth. Driven Sprocket — 25tooth. Coal Experiments Continue EBOP Whakatane report in their June news letter on their use of Huntly Nuts. Fa 9 has been fitted with an experimental grate having a top air riser fitted along the centre line as indicated in the photo. When fired a little and often it was found to reduce the amount of smoke which is a problem with the soft coal. There was however more ash in the ashpan than with other coal. The effect of the top air riser could be observed with the fire bed level just below the air holes showing a jet of flame coming off each one as the smoke gases burned. Dates to Note 24 - 26 October Labour Weekend ! Havelock North and New Plymouth. 7 - 11 January 2016 ME Convention Tauranga. The HVMES run at the track at Petone 1300 to 1600hrs on fine Sundays -- Welcome Maidstone MES, Upper Hutt, running on the 1st and 3rd Sundays of the month. - Welcome there too.

© Copyright 2026