Rudin®BreadCasing, the new revolution!

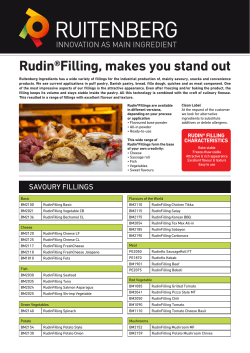

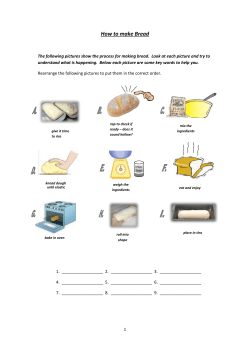

Rudin®BreadCasing, the new revolution! For many years now, Ruitenberg Ingredients has been well-known in the meat industry for its expertise in alginate-based casings. This range of casings, called Rudin®VegaCasing, is used in combination with the principle of co-extrusion. Together with our knowledge of bakery products, this experience has resulted in the development of a totally new concept: Rudin®BreadCasing. Concept Rudin®BreadCasing is a lowfat, food-safe casing made from bread dough. Due to its special composition, it is possible to produce bread products with the use of existing coextrusion. After production it can be baked directly or stored in the freezer. Applications Our Rudin®BreadCasing can be used in a variety of snack products, with meat emulsion a perfect example of a filling. Besides meat dough, we offer a wide range of other fillings suitable for co-extrusion as well. CO-EXTRUSIOn Co-extrusion is widely used in food production to produce filled confectionary products, filled breakfast cereals, filled snacks, etc. In meat processing, it can be used to coat sausages with an outer skin. The advantages of co-extrusion are obvious: co-extrusion is a cost-effective method for large-scale production. Furthermore, uniformity of the end product is guaranteed. Bread dough Using standard bread dough in combination with co-extrusion will damage the structure of the dough, making it unsuitable for use in extrusion. After extensive research by our R&D team, Ruitenberg Ingredients is proud to introduce Rudin®BreadCasing – the first bread dough that keeps its structure after co-extrusion. Know-how The implementation of Rudin® BreadCasing is done with the help of the technologists of Ruitenberg Ingredients. In partnership with our client, we guarantee a solution that works to ensure a long-term relationship. The success of this formula is what makes Ruitenberg ingredients such an established name in the food industry – worldwide. RUDIN® BREADCASING A real breakthrough for the meat industry! Now available at Ruitenberg Ingredients. Did you know... At your request we look for alternative ingredients to substitute additives or allergens to create a clean label. For more information please contact our team. Tel: +31(0)571-270 000 Fax: +31(0)571-270 217 E-mail: [email protected] Internet: www.ruitenberg.com Now available: gluten free Gluten is a protein found in wheat, rye, barley or any of their crossbred varieties and derivatives. In baking, gluten is an important component within flour that keeps the air inside the baked product. As such, gluten is found in many processed and packaged foods. More than 55 diseases have been linked to gluten, the protein found in wheat, rye, and barley. It’s estimated that 99% of the people who have either gluten intolerance or celiac disease are never diagnosed. Market Sales of gluten-free food products have been increasing in both volume and value at a faster rate than lactose-free and diabetic food products, for example. Gluten-free has been described by consumers as: “a mainstream sensation, embraced both out of necessity and as a personal choice toward achieving a healthier lifestyle.” Rudin®BreadCasing GF To produce gluten-free bread products, our team of technologists has developed a special gluten-free Rudin®BreadCasing, called Rudin®BreadCasing GF. Recipe Rudin®BreadCasing Method, application Mix all ingredients for approx. 9 minutes (2 minutes at low speed and 7 minutes at high speed) in a dough kneader. Dough temperature: 20–22°C. Prepare the dough like a standard bread type of dough. After mixing, the dough is directly ready to use for further processing. Preparation in a bowl chopper is also possible. Use (partly) crushed ice to prevent dough temperature increasing. Don’t mix or chop the dough too long in the bowl chopper. When there’s some consistency in the dough, it’s ready. Product: Rudin®BreadCasing can be prepared in your bowl chopper PB0600 Suggestion Co-extrude the dough in combination with one of the Rudin®Filling products or other (meat) fillings. Bake the products for 7 minutes at 250°C with some steam. Bake the products for a short time at a high temperature! This is just a recommendation, as every oven is different and needs to be tested for the right settings for baking the products properly. Another option is steam-cooking the products or even deep-frying them. The cooking time of the products depends on size and weight and should be tested. Rudin®BreadCasing Ingredients: [%] [g] Rudin®BreadCasing 70,4 1000 Water (cold, 0-2°C.) 29,6 420 Total 100,0 1420 Additional information If something is unclear, or if you require more information about the possibilities of other Rudin products, please contact us at [email protected]. Or call us on +31 (0)571 270 000 and ask for the Application Technologist Bakery.

© Copyright 2026