NCSOIL - Plant and Soil Sciences eLibrary

Soil Series 122

Winter 1986

NITROGEN CARBON

TRANSFORMATION IN SOIL

(NCSOIL)

USER’S GUIDE

BY

J.D. HASKETT

J.A.E. MOLINA

C.E. CLAPP

The University of Minnesota, including the Agricultural Experiment Station, is committed

to the policy that all persons shall have equal access to its programs, facilities, and

employment without regard to race, creed, color, sex, national origin, handicap, age, or

veteran status.

Department of Soil Science, Univeristy of Minnesota St. Paul Minnesota

Table of Contents:

NCSOIL Flow Diagram.................................................................................................... 4

Introduction ................................................................................................................... 5

The Structure of NCSOIL ................................................................................................ 6

The Time Step ................................................................................................................ 7

I The Components of the Model ...................................................................................... 7

The Plant Residue Pool................................................................................................... 8

Carbon Flow ................................................................................................................... 8

Transfer of Carbon to the Second Pool ........................................................................... 8

Breakdown of Humads .................................................................................................... 9

Nitrogen

................................................................................................................. 10

Transfer of Nitrogen to Second Pool ............................................................................. 12

Simplifying assumptions of Nitrogen Flow..................................................................... 13

Conditions of Excess Carbon ....................................................................................... 14

II. The Functioning Model ............................................................................................. 15

Day 1 ................................................................................................................. 15

Day 2 ................................................................................................................. 16

Day 3 ................................................................................................................. 16

III. Using the Model ...................................................................................................... 16

Data Entry

................................................................................................................. 17

Parameter locations in an NCDATA File ....................................................................... 17

Line One ............................................................................................................. 18

Line Two ............................................................................................................. 19

Line Three .......................................................................................................... 19

Line Four ............................................................................................................ 19

Line Five ............................................................................................................. 20

Line Six............................................................................................................... 20

Line Seven ......................................................................................................... 20

Lines Eight and Nine .......................................................................................... 20

Example of an NCDATA File .............................................................................. 21

2

Output ........................................................................................................................... 21

Appendix ....................................................................................................................... 23

1) Timestep Selection.................................................................................................... 23

2) Data Entry using NCDATA........................................................................................ 24

A) General ............................................................................................................... 24

B) Values for the Parameters .................................................................................. 24

C) Units ................................................................................................................... 24

D) Locations by Parameter Designation ................................................................. 25

E) Definitions of Parameter Designations ............................................................... 25

F) Example of an NCDATA File .............................................................................. 28

3) NCOPUT Column Key ............................................................................................. 28

A) Headings ............................................................................................................ 28

B) Group Titles ........................................................................................................ 29

4) Running the Model on Cyber ................................................................................... 30

A) Example of a run on the Cyber Computer .......................................................... 31

B) A Brief NOS Tutorial ........................................................................................... 32

NOS Commands in Brief ................................................................................... 36

C) A Brief XEDI Tutorial ........................................................................................... 37

XEDIT Commands in Brief ................................................................................. 39

D) A Brief MINITAB Tutorial .................................................................................... 40

Key to NCTAB Columns .................................................................................... 41

References.................................................................................................................... 43

3

4

INTRODUCTION:

NCSOIL is a program which simulates the biological transformation of

nitrogen and carbon in the soil: plant residue decomposition, nitrification, denitrification,

immobilization and mineralization of nitrogen, and soil organic matter decomposition

and formation. The program assumes a homogeneous soil at a constant temperature

and water content. For those interested in the underlying concepts and mathematics of

NCSOIL, the original articles presenting these aspects are referenced in the appendix

(Molina et al. 1983, Clay et al. 1984, Clay et al. 1985, Hadas et al. 1987).

Models have inherent limitations which are like those described in the

story that LewisCarrol tells about the methodical map makers. This group wished to

constantly increase the accuracy of their maps by incorporating ever increasing levels of

detail. Starting with maps of a scale of 1:72,000, they eventually managed to create a

map which had a scale of 1:1. However the farmers refused to let them lay it down.

This story illustrates that there is always a trade-off between the accuracy

of the model and its size and workability. A model is necessarily less accurate than the

thing it represents and as a modeler one can only hope that one has achieved the level

of detail which permits the model to fulfill its objectives.

Another limitation of computer models can also be illustrated by Carlyle's

observation about the recording of history. He said that although history occurs

simultaneously it is recorded sequentially. Similarly the NCSOIL model attempts to

mimic a system in which all of the processes which are operative occur simultaneously.

Yet the computer must follow sequential commands one at a time. This "round holesquare peg" problem is addressed through the convention of the timestep (see also

page 3 and appendix): the interval of time during which the computer calculates all the

various occurrences in the system and then records them at the end of the timestep "as

if" they had all occurred together.

The model lends itself to examining the soil system as a dynamic entity

rather than simply reading about it as a static entity. It is hoped that by manipulating the

program the user will gain a feel for the nitrogen -carbon cycle in the soil.

Although this manual is intended for a general audience, a conscious

decision was made to aim the text at the undergraduate user with little previous

modeling experience. This gives the manual the broadest applicability since it can then

be used as a teaching tool as well as a reference guide.

The directions which follow assume a certain familiarity with the Cyber computer system

and with the Xedit line editor on that system (a list of the CYBER commands

necessary to access the system, an example of a computational session with

CYBER and a list of references for using the system, appears in section 4 of the

appendix).

5

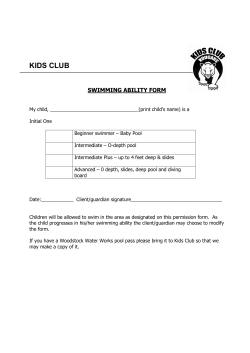

THE STRUCTURE OF NCSOIL:

The program NCSOIL simulates the biological cycling of nitrogen (N) and carbon

(C) as these elements move between a series of pools or compartments. NCSOIL

computes this flow through a system of controlling rates and decisional switches. The

rate controlling aspect may be envisioned as the faucets and drains on a series of

interconnected bathtubs which feed

into one another ( Figure 1), and whose levels are controlled by the rates of inflow and

the rates of outflow. Decisional switches are similar to switches on a railroad line. That

is, they are forks in a road, the program chooses one path or the other depending on

the current circumstances.

There are many flow configurations which arise due to different initial

circumstances and the interplay of factors in the system. This is a longwinded way of

saying that the flows do not follow one linear path. It is not A goes to B goes to C. After

"A" a number of different alternate paths can be followed depending on conditions. Each

path leads to a distinct series of consequences. This is especially useful for modeling

mutually exclusive biological occurrences at any particular place in the soil.

6

THE TIME STEP

In order to mimic the functioning of the system as it changes through time

the program uses a time step (A t). The program starts at time zero (t=O) and does a

series of sequential calculations which are intended to represent the simultaneous

interactions occurring during the first time step (to+A t). The

results of these calculations form the basis for the next pass through the program which

simulates the interactions during the next time step (ti +A t)

The modeller selects the duration of the time step which can vary from minutes to

weeks.(this will be detailed in the input section of the appendix).

1. THE COMPONENTS OF THE MODEL

When viewed diagramatically NCSOIL resembles a complex wiring

diagram, which can be understood if it is broken down into sections. NCSOIL models

the cyclical portions of the transformation system sequentially. In order to do this, it

does quite a bit of feeding back on itself. The initiation of decay of a residue left by a

crop on the surface of the soil, is a convenient starting place. In a sense this is the

reservoir which drains into the bathtubs of the system (ignoring for a moment the

degree to which they are already filled).

The Plant Residue Pool

The composition of the plant residue pool is very complex in nature,

consisting of all of the compounds found in dead plants. However this complexity is

skirted by the program, which divides plant residue into those portions which are only

decomposed slowly (which will be referred to as resistant), and those portions which are

labile, that is, readily decomposed.

This residue is what we have to start with and it is immediately subject to

microbial attack. The rate at which this decay proceeds is controlled by a number of

factors, including: temperature, available water, and the carbon - nitrogen ratios (C/N) of

each portion of the residue. Each portion of the residue has a specific rate of decay,

which is inversely related to its C/N ratio. Simply, the more C there is relative to a given

amount of N, the slower decay will be in the absence of other sources of N. Specific

decay rates are measured experimentally for a given temperature and water content.

Associated with the specific decay rate is the influence of the decomposers' population

during the experiment.

7

Carbon Flow

Carbon flow is accomplished by microbial consumption of plant residues. A

significant portion of the carbon removed from the residue by decay is lost as carbon

dioxide. Carbon flow from the residue pool into the first microbial population pool is

shown in Figure 2.

At the level of the microbial population, simplifying assumptions are made in the

same way that the composition of the crop residue was simplified. The cellular

constituents of the populations within this pool are again distinguished only as being

either resistant or labile. A single C/N ratio for each portion of the population of

microbes is assigned based on an estimated average of the various C/N ratios found.

Transfer of Carbon to the Second Pool

The transfer of C between the first and second pool is treated similarly to

that which occurred between the residue and the microbial pool. The second pool

consists of those products of microbial decomposition which are stable enough to

persist in the soil, but which have a much shorter residence time than soil humus.

These compounds are the humads. The flow from the microbial pool into the humad

pool differs from the flow from the residues into the microbial pool in that some of the C

which flows out of pool one (microbial pool) as a result of decay flows back into it

directly in a feedback loop. This is due to internal reincorporation occurring within this

pool. Thus, the initial flow of C lost to the microbial pool is split in three directions;

volatilization, recycling, and incorporation into the pool of humads (Figure 3).

8

Breakdown of the Humads

The final stage in this carbonacieous progression is the breakdown of humads in

the humus (Figure 4). Carbon from the humads is released by decomposition and is

incorporated into the humic material in the soil, lost to volatilization, or incorporated into

the microbial biomass.

9

Although similar to the two previous decay stages, the next stage incorporates

another aspect which can affect residue decomposition. This is the presence or

absence of soil tillage. As far as the program is concerned this is like an on/off switch.

Either there is tillage or there isn't. If there is tillage, the switch is on and this will transfer

a certain amount of C to a tillage pool from the humad pool. If there is no tillage, the

switch is off and there is no addition. The tillage pool decomposes more rapidly than the

humad pool. This is intended to mimic the increased microbial activity and hence the

increased decomposition of relatively stable compounds associated with the physical

disturbance of the soil produced by tillage. In this program there is only provision for one

instance of such an increase.

The final stage of C decomposition is where the initial C compartments are

redefined and made ready for the next time step. The end point can be viewed as

cyclical since some of the C has been reabsorbed by the microbial biomass, the C in

the humic layer is slowly reintroduced into the biosphere after a long period of being

sequestered, and the C volatilized as carbon dioxide is of course now available for

photosynthetic fixation.

It is important to note that although the microbes are only quantified at one

location in the program (the microbial pool), they act on other pools at several points in

the program. These points include the three decay processes already mentioned (decay

of residues, decay of microbial biomass, decay of humads).

Nitrogen Flow

N flow is treated similarly to C flow. Examples are presented which show how

flow is treated by the system.

For simplicity let us first examine a situation in which the residue to be

decomposed contains a large amount of N relative to the amount required for

decomposition. Let us also assume that the concentrations of ammonium-N and nitrateN in the soil are negligible.

In this instance the first transformation of N resulting from residue decay will be

analogous to that of C. The amount of N which moves is dependent on the amount of C

which moves and these factors are related through the C/N ratio. Of the N released by

decay only a certain amount will be added to the microbial biomass. This amount is

related to the C/N ratio of this biomass, since the microbes only add as much N as they

need for that amount of C incorporated ( in N limiting situations this is reversed and they

add only as much C as the amount of N available will permit, the leftover being

volitalized as carbon dioxide). This relation is controlled by the differences in the C/N

ratio of the residue which constitutes the supply, versus the C/N ratio of the microbial

biomass which constitutes the demand. Here we are postulating a lower C/N ratio for

the residue than for the microbial pool, so that as a result of residue decomposition N is

available in excess.

10

The N released but not incorporated into biomass goes into the ammonium pool.

This is different from the volatilization of C as carbon dioxide since the C is lost to the

model, while ammonium remains in the system, available for further cycling (Figure 5).

Let us now follow the flow of N through the various trophic levels which we have already

outlined for C.

11

Transfer of Nitrogen to the Second Pool

The transfer of N from the microbial pool to the humad pool (Figure 6) is

accomplished by the death and decay of cells in pool one. Some of the released N is

taken up by neighboring microbial cells, hence the recycling of some of the released N.

Another portion of the N is stabilized by the microbes in the form of the humads. The N

which is not absorbed into cell biomass or stabilized as humads is released as

ammonium.

The N in the humad pool released by decay, is incorporated into the soil humus

and into the microbial biomass pool (Figure 7).

The tillage factor is incorporated at this point and its operation is exactly identical

to C. Decomposition caused by tillage releases an additional infusion of N. This infusion

causes the switch to be set into the "off" position for the rest of the model's run, since

the effect of tillage is modelled to occur for only one timestep.

Having examined the part of the N flow which parallels the C flow, we now turn

our attention to the fate of the ammonium which was released.

Unlike the carbon dioxide which was lost, ammonium rarely disappears from a

soil system as a gas. Rather it flows into a soil pool of ammonium (Figure 8). The

ammonium pool may exist in the soil independently of the initial movement of N from the

residue thorough the two microbial pools. In the situation we are considering, the

release of ammonium at the various stages adds to this pre-existing pool.

12

In nature, the transformation of ammonium into nitrate is a two stage process

involving two distinct populations of bacteria. In the first step ammonium is transformed

into nitrite by the first population, and in the second step this nitrite is converted to

nitrate by the second population.

It is assumed by the model that ammonium is converted directly into nitrate. This

is a valid simplification because nitrite is a very short lived intermediate in most soils. In

other words, the conversion of ammonium to nitrite is the rate limiting step, and the

amount of nitrite present at any given time is considered negligible by the model.

A certain portion of the nitrate is denitrified by another bacterial population and is

lost by denitrification to the system as a gas (Figure 9).

Thus, the ammonium which flowed out of the decay steps is handed along from

the ammonium pool to the nitrate pool and ultimately may be converted to N2 gas. The

portion of the N which is held at each stage of the transformation constitutes the

quantity present in that pool.

So far we have been looking at possibly the simplest case. In this case the

necessary quantities of both N and C are supplied by the residue and then flow through

the system. This was done in order to identify all the pools in the system and give some

idea of how they relate to one another. Now let us turn to the other conditions which can

occur, in which these simple optimal levels are not present. In this instance the flow of C

is unchanged (although the flow rates will be changed), but there are signifigant

changes in the flows of N.

13

Conditions of Excess Carbon

The complexity of the system increases when the C/N ratio of the residue

is higher than the minimum amount required to provide the necessary building blocks

for microbial assimilation. Without another input of N, decay could not proceed at its

maximum rate. Once again the pools of ammonium-N and nitrate-N become important.

If such pools are present in the soil part of their contents furnish N for microbial

assimilation resulting from residue decomposition. The drain on both pools is

simultaneous and occurs in proportion to their relative quantities in the soil. For

example, if 25% of the soil N was in the form of ammonium and 75% was in the form of

nitrate, the model would draw 25% of the required N from the ammonium pool and 75%

from the nitrate pool.

The N drawn from the ammonium and nitrate pools is incorporated into the

microbial pool (Figure 10) in the quantities allowed by the incorporation of C and

required by the C/N ratio of the microbial pool. The N then cycles through the system in

the manner previously described.

If, however, these sources of N are inadequate, N fixed from the,

atmosphere by free-living N fixing bacteria can be used as an N source. This N also

enters the cycle by incorporation into the microbial pool. If all of these sources of N

prove inadequate, then the rate of decomposition of the residue slows down and less C

moves through the system. This situation stresses the importance of the influence of N

on the rate of decomposition.

14

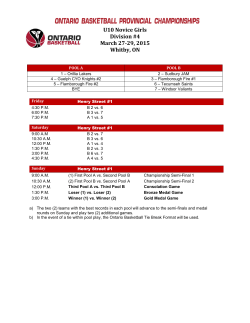

II. THE FUNCTIONING MODEL

Having examined each portion of the model individually, let us now put them

together and see how they work in unison. It is best to have the whole flow chart (page

i) visible at this point to follow on it the steps outlined in the verbal description.

For example, at the start of this model run, the residue has a high C/N ratio,

pools of ammonium and nitrate each contain 50% of the soil inorganic N, tillage will

occur, all environmental factors such as temperature and moisture are optimal for

decomposition. For simplicity, the timestep is equal to one day, although in an actual

model run it would probably be much shorter.

Day 1: Breakdown of residue begins, the initial flush of decomposition of the

labile (easily decomposed)and recalcitrant portions of the residue provides sufficient N

for assimilation of the C released. Some of the C released by decomposition of the

residue is lost as carbon dioxide. Some of the N released from the residue goes into the

ammonium pool. The breakdown of a portion of the microbial pool occurs. Some of the

C released by this process is incorporated into the humad pool while the rest is either

recycled into the microbial pool or lost as carbon dioxide. Similarly the N released by the

microbial pool's decomposition is either stabilized into the humad pool, recycled back

into the microbial pool or goes into the ammonium pool. Breakdown of the humad pool

begins and at this point the tillage factor makes its single appearance adding a certain

portion of N and C from the humad to the tillage pool. The combined decomposition of

the humad and tillage pools releases C which is either recycled to the microbial pool or

lost as carbon dioxide. A tiny portion (not acknowledged by the program) of this

released C goes into the humus layer sink. The amount of N incorporated into the

humus is also very small, the balance being either recycled into the microbial pool or

going to the ammonium pool. The ammonium pool has been increased by additions at

every level of decompostion thus far. It also has been decreased since a certain portion

of the ammonium is converted to nitrate. Of this nitrate, a certain portion is converted to

N2 gas and lost to the

15

system. It is assumed that in this situation both nitrification and denitrification occur

simultaneously.

Day 2: It is assumed that the labile portion of the residue has been exhausted,

and that the quantity of N provided by the decomposition of the remaining recalcitrant

portion is now inadequate to meet the microbial assimilation demand. The model must

now draw N from the ammonium and nitrate pools to supply the microbial pool. With

regard to ammonium, the flow of N has thus been reversed. Otherwise the model

proceeds as it did on the first day except that now there is no addition due to the tillage

factor. Again at the end of this time step all pools have been recalculated and another

day is considered to have occurred.

Day 3: The decompositional demands of the C rich resistant portion of the

residue now exceed the quantities of N which can be drawn from the depleted nitrate

and ammonium pools. Even with the addition of N fixed by free living organisms, the

quantity of N available at the first step of the decomposition process is inadequate. Thus

the rate of residue decomposition now slows down. The decomposition rates of the

other pools won't be affected until the next timestep. The size of all pools have now

been recalculated and the run is over. The changes which have occurred are as follows:

1) The pool of residue has decreased, especially the labile portion.

2) The microbial pool has increased due to greater additions to its biomass than to its

degradation.

3) The humic pool has been slightly increased.

4) The pools of nitrate and ammonium have been depleted by greater microbial

assimilation than N mineralization.

5) Some N has been fixed from the atmosphere and incorporated into the soil pools.

III. USING THE MODEL

The appendix contains subsections with references and keys for:

a)Data entry via NCDATA (including a key to parameter designations).

b)The meaning of NCSOIL output columns.

c)Timestep selection.

d)Running the model on the Cyber computer including subsections on the use of: i)

NOS operating system commands ii) Xedit line editor iii) Minitab statistical package

Some of these topics are treated in more detail here.

16

Data Entry:

In order for NCSOIL to run it needs a set of input values which define the initial

soil system conditions.. These constitute the starting point which the model then acts on

and modifies in the course of a particular program run.

To set these parameters the user needs to access a file called "NCDATA" This

file is separate from the file "NCSOIL" which contains the program NCSOIL. NCDATA

can be accessed without accessing NCSOIL. Thus it is not necessary to make

modifications to NCSOIL itself in order to model various situations. This avoids the

possibility of entering errors to the main program in the process of entering input data.

The file NCDATA consists of nine lines of numbers. Each number is an input

parameter and its meaning is defined by its specific location in NCDATA. This means

that the user must be careful when changing these values to make sure that the location

of the desired change is maintained and that all parameters are still defined even if they

are defined as zero. All these parameters have designations within the program

NCSOIL; but the user is not required to use these designations in setting up NCDATA in

which the numerical values suffice (see page 18 for an NCDATA example). However,

for ease of use, these designations are introduced here to define the meanings of the

numbers in NCDATA and the key to NCDATA, which appears in the appendix, also

relies on them.

The cyber computer is very inflexible about the format of the data. Incorrectly

formated data will cause the computer either to refuse to run the program, or to print

pages of error messages, or both. Therefore these rules must be followed:

1) Every number must have a decimal point. Thus, one hundred would be

entered as "'! 00.", while one hundreth would be entered as ".01". (There are two

exceptions to this rule in NCDATA which will be discussed later.)

2)Each number must be separated from every other number by a comma.

However, no comma is needed at the beginning or end of a line. Thus a correct line of

numbers would look like this: 100., 10.,. 16,0.

NCDATA itself consists of nine lines of numbers. These numbers can be altered

using the XEDIT line editor. A basic guide to the use of XEDIT is provided in the

appendix. The following is a line by line definition of the various parameters which must

be set in NCDATA. These parameters define the initial soil conditions within which the

model will operate.

Parameter Locations in an NCDATA File

TO,T1,LENGTH, INTER

CONC(l),CONC(l 4),C0NC(2),C0NC(6),C0NC(1 5),CONC(l 6)

17

CF(l),CF(l 4),CF(2),CF(1 5),CF(l 6),CFTILL

EFFAC(1),EFFAC(2),EFFAC(1 5),EFFAC(l 6),EFSINK

CN(l 5),CN(l 6),CSTDEN,CSTSYM

FERNH4,FERN03

AER,TILL

CPER(1 5),CPER(l 6),CPER(1),CPER(1 4),CPER(2),CPER(6)

PER(l),PER(l 4),PER(2),PER(6),PER(8),PER(1 0),PER(l 1),PER(l 5),PER(l 6)

Line One

The first value in line one is time zero (TO) or the starting point for the program.

The next value is time one (Tl), the starting point of the next timestep. This value has

units of days or fractions of days. The duration of the timestep is equal to T1 minus TO.

Thus if one wanted the model to increment in terms of days with TO equal to zero, then

T1 would be 1, for weeks it would be 7, and for hours it would be .04167. TO dosn't

have to be equal to zero. For example, if one were simulating the growing season with

data whose time designations were in days after January 1, then TO might be equal to

155 (early May). A time step with a duration of one week could then be obtained by

setting T1 equal to 162. It is important to note that there is a trade off between accuracy

and computer cost inherent in the size of the time step. The smaller the time step the

more closely the model approaches the instantaneous changes which are occurring in

the world mimicked by the model. However the smaller the time step, the more

numerous must be the computations for any given period of time. This is the trade off

which the user must keep in mind when setting up the size of the time steps. That is,

how large a timestep can be used while maintaining the desired accuracy. A further

discussion of selecting a timestep appears in the appendix.

The next two numbers in line one are the exceptions to the decimal point rule.

This is because they are integers and are recognized by the computer as such. The first

of these numbers defines how many time steps the run will use. In a model run

representing a day and incrementing by hours, this number would be 24. In a run

representing a week and incrementing by days this number would be 7. The second

integer in this line refers to the number of time steps between each generation of output

data. This parameter is included for convenience and ease of data handling, so that the

model can be extremely accurate by the use of many small time steps, while generating

only a manageable amount of relevant information. For example, suppose that the

modeller is interested in the decomposition of residue and its effects on the soil over a

period of a week. For a high degree of accuracy the modeller selects a time step of one

hour. However the changes in the soil can be effectively monitored on a daily basis,

while the values at each hour would not show significant changes and would be

unwieldy and confusing to work with. For units of time the modeller selects days. For

this situation the first number (TO) would be 0. The second number (T1), the time step

of one hour would be .04167(1/24th of a day), the third number ("LENGTH" i.e. the

number of time steps) would be 168 (the number of hours in the week), and the last

number ("INTER") would be 24 (the number of hours/timesteps between outputs).

18

Line Two

The line two in NCDATA defines the size of the various C pools at the outset

of the model run. These pools are the residue,the microbial pool, and the humad pool.

Each pool is divided into labile and resistant fractions and each fraction is defined by a

separate input parameter. Thus there are six numbers in this line, representing the

labile and resistant fractions of the three pools. The units of these pools are defined by

the user, but do not appear directly in the program. Virtually any units are acceptable if

the same chosen units are used throughout. The output file will also be defined in the

same units. For example both grams of C per 100 grams of soil, and kilograms of C per

100 kilograms of soil would be acceptable. It is important that the same units be

used throughout this line and that the user keeps track of which units are in use.

The order of the various pools which are designated by "CONC" followed by a number,

is outlined in the appendix. The numbers used to identify the various pools are as

follows: (15) residue labile, (16) residue resistant, (1) pool one labile, (14) pool one

resistant, (6) pool two labile (tillage pool), (2) pool two resistant (humad pool). These

numbers retain their pool fraction meanings when referred to any of the other

parameters such as efficiency factors and C/N ratios.

Line Three

The numbers in the third line define the specific rates of decomposition of the

various C pools described above. These rate constants are expressed in fractions

per unit time. The unit time has been chosen in defining the numbers of the first line in

NCDATA. Thus, typical rates might be: pool one labile fraction decomposing at 0.332

per day, while pool one resistant fraction might be decomposing at 0.04 per day. The

specific rates are independent of the units used to define the pools, but the amount of

each pool which is actually decomposed per unit time is dependent on the preselected

units which define the pool. Thus, if 100 grams of labile C are present in the residue

along with an equal amount of resistant C, then, in this instance, 33.2 grams would

decay after the first day, while 4 grams of resistant C would decay in the same time.

The specific rates of decomposition of the various pool fractions are identified by CF

followed by a number, with the exception of the resistant fraction of pool two which is

designated as CFTILL, and is directly connected to the tillage factor discussed before.

Line Four

The definition of the efficiency factors constitutes the fourth line of the file.

These partition the C released by decomposition into that part which is actually

absorbed into biomass (under conditions of no N limitation) and that part which is

released as carbon dioxide. There are five efficiency factors. The first two in the line

deal with the efficiency of uptake of the recycled C available to pool one from the

decomposition of pools one and two. The next two numbers refer to pool one's

efficiency in absorbing C released by the labile and resistant fractions of the residue.

19

These parameters are designated by "EFFAC" followed by a number. The last

parameter in this line is the efficiency of uptake of pool two, this is designated simply as

"EFSINK". Since there is only one such parameter no numerical designation is needed.

Line Five

The first two values in this line are the carbon-nitrogen ratios of the labile and

resistant fractions (respectively) of the residue. These are referred to as "CN" followed

by a numerical designation.The numerical designation is a proportionality constant

which determines the amount of nitrate nitrogen which will be converted into N2 gas per

unit of C decomposed (i.e. C per N). This unique parameter is designated as

"CSTIDEN" and characterizes the process of denitrification. It is followed by the

parameter which defines the amount of N added (per unit of residue C decomposed) to

the system as a result of non-symbiotic N fixation, known here as "CSTSYM". Both of

these parameters are unitless ratios.

Line Six

The amount of N initially present in the soil is defined by the parameters of

the sixth line. The designation "FERNI-14" refers to the amount of ammonium in the

soil. The designation "FERNOW which follows refers to the amount of nitrate in the soil.

These include both that amount which was in the soil and that amount which was

initially added as fertilizer. The units of these amounts are the same as those defined for

the CONC series, which was defined in line two.

Line Seven

The aeration factor "AER", is the first value of the seventh line. This parameter

deals only with the effect of soil aeration on the nitrification - denitrification fork in the

program. If the soil is sufficiently oxygenated then only nitrification will occur and this

parameter is defined as 1.0. If the soil is flooded and anaerobic conditions prevail, then

denitrification will occur and this parameter is defined as 2.0. If the soil is partially

saturated both processes may be occurring in different parts of a given volume of soil

and the designation is 3.0 which causes both processes to be modeled simultaneously.

The other value in this line is the tillage factor "TILL". If the soil was tilled this parameter

is given a value of 1.0 and the tillage effect will be performed during the first timestep. If

no tillage was performed the value zero.

Lines Eight and Nine

The next two lines refer to the modeling of tracer experiments. In these

experiments a readily identifiable isotope of C or N is followed as it flows through the

system. The user can designate where in the system the tracer is to originate. Thus, line

eight contains the C tracer designations "CPER" followed by numerical designation of

the pool fraction. Line nine contains the designations for the tracer N called "PER", also

20

followed by numerical designations. Three of these (8,10,11) refer to the ammonium,

nitrate, and dinitrogen pools. All of these parameters are ratios of tracer N or C to the

total amount in the pools they are associated with. Thus in a run in which half of the

residue resistant C was labeled, CPER(l 6) would have the value of 0.5.

These are all the input parameters which can be varied to simulate various soil

conditions using NCSOIL. The user may wish to try to duplicate the conditions in a

particular soil, to see how it behaves, or create entirely hypothetical situations to see

how they run their course.

Example of an NCDATA File:

0.,.1,100,10

.56,.44,2650.,0.,2500.,2500.

.332,.0404,.006,.75,.02,.16

.0,.0,.0,.0,.2

1000.,1000.,150.,10.

0.,200.

2.,1.

1.,1.,1.,1.,1.,1.

0.,0.,0.,0.,0.,0.,1.,0.,0.

Output:

Once NCSOIL has been run it generates a voluminous output. However this

output is systematically organized into sections which are labeled as follows:

INORGANIC-N (the amounts of this substance in various inorganic forms), Cumul-N

(the cumulative concentrations of N in various forms), CUMUL-C02-C (the cumulative

release of carbon dioxide from various pools), ORGANIC-C (the amounts of C in

various pools other than carbon dioxide), MASS BALANCE (this keeps track of the total

amounts of each substance in the system and makes sure that all of it is accounted for,

so that the "books" balance), N1 5 FRACTION (this is the fraction of this N isotope in

various pools), N1 5 CONTENT (this is the actual concentrations of the isotope in the

same pools),C14 CONTENT (similarly, this is the actual concentrations of radiolabeled

C in various pools), C1 4 FRACTION (this is the fraction of radiolabeled C in the various

pools).

In each of these sections columns of numbers appear, the first column is labeled

"DAY". This is the column which identifies the time step which corresponds to that row

of numbers in each column. The first number in the day column is usually zero and,

thus, this row presents the initial values of these parameters at the start of the run,

corresponding to the numbers in NCDATA.

In order to decipher the meanings of the individual columns refer to the key

provided in the appendix. This will permit the user to follow changes in various aspects

of the system through time.

21

Although the type of output described here is very complete, it is generally

difficult to get an idea of what is happening in the system just from columns of numbers.

For this reason NCSOIL also generates output which is formatted to be used by the

"MINITAB" statistical package available on CYBER. A complete description of how to

use MINITAB is beyond the scope of this text, but a useful manual is available. A brief

summary of the basic MINITAB commands necessary to produce graphs, as well as a

key to the meaning of the various MINITAB column numbers, is provided in the

appendix.

22

APPENDIX:

This appendix has four sections. The first three are: 1) an explaination of

timestep selection, 2) a guide and key to the creation of the input file NCDATA, and 3) a

key to the output columns generated by the output file NCOPUT. These sections deal

with the internal operation of the program itself. The last section is a guide to the

external information needed to run the program. This includes a description of the Cyber

computer system and an example of what a computing session on Cyber would look

like. This section also includes subsections which detail the basic commands necessary

to use the Cyber system, the MINITAB graphics package and the XEDIT line editor. The

commands listed in these sections are the minimum necessary to run the program. For

a more complete description of these systems see the books listed in the reference

section which follows the appendix (page 42).

1) Timestep selection:

The two main considerations in setting a timestep are the level of accuracy

required and the amount of time and money available. As the size of the timestep

diminishes, the accuracy of the model increases. The level of accuracy is determined in

part by accuracy of the input parameters used. To set the timestep to the desired level

of accuracy one should start with a relatively large timestep and do successive runs of

the model until the results are invariant to the level of accuracy desired. For example

suppose that with a time step of 1 week (T1 =7,and TO=O, where TO is the input

parameter which defines the start of the first timestep, and T1 is the start of the next

timestep and, both parameters are in days) a particular output parameter had a value of

22.5934. When the timestep was reduced to 1 day (T1 =1) this parameter had a value

of 21. 3356. When the timestep was reduced to a half day (T1 =0.5) the parameter had

a value of 21.3328. The first timestep reduction was necessary since it changed the

output, while the second reduction was unnecessary since the change it produced was

outside the model's level of accuracy.

With the speed of the mainframe computer on which this model runs, changes in

timestep have virtually no effect on the operators perceived time of operation. However,

more timesteps do marginally increase the cost of running the model and this may be of

concern to some users.

A secondary consideration, with respect to timesteps, is how often the user

wishes the value of a particular output parameter expressed. For example, a timestep of

one minute may be desired for accuracy, while significant changes may only be

occuring on an hourly basis. Here the timestep would be one minute (T1 =0.0006944),

but the output of data would only occur every sixty timesteps (INTER=60, where INTER

is the input parameter determining the number of timesteps between output

expressions).

23

2) Data Entry Using NCDATA

A) General:

The file NCDATA must have a particular form if it is to be correctly read and

interpreted by the computer. It Is vitally important that the input parameters be in

their correct locations.

This key therefore, has two sections. The first section shows the locations of the

input parameters using symbols and acronyms. The second section defines these

symbols and acronyms. Finally there is an example of what a correctly created

NCDATA file looks like. As previously stated in the text, the rules of formatting are:

1) Every number must have a decimal point although defining zeros are not

necessary. Thus one hundred would be entered as "l 00.", while one one hundredth

would be entered as ".01 ".The exceptions to this rule are the LENGTH and INTER

parameters, which are integers and thus do not need decimal points. These parameters

appear in the first line of the NCDATA file.

2) Each number must be separated from every other number by a comma.

However no comma is needed at the beginning or end of a line. Thus a correct line of

numbers would look like this: 100.,l 0.,.16,0.

B) Values for the Parameters:

Although the user can designate any values desired for the various input

parameters, the new user may not know a likely range for the parameters. This is

especially true of the rate controlling internal parameters such as the efficiency factors

and the specific rates of decomposition. To get the user started, some values have

been provided for those essential internal parameters. While the authors believe that

these values are valid within a broad range of conditions, they are by no means the only

or "true" values of these parameters. Others working in this field would no doubt use

different values. The object here is merely to spare the new user an extensive literature

search, and to allow the user to begin experimenting with various soil situations as soon

as possible. Initial physical parameters such as the C and N contents of the soil, its

moisture content, and whether or not tillage will occur, seem sufficiently clear to allow

the new user to define them without external guidance. This is also true of the

parameters which define the degree of radiolabeling. Since these are merely fractions,

the user selects which pool should be labelled and what fraction of that pool will be

labelled with isotope.

C) Units:

The user may select any units which are appropriate to the situation to be

studied. Typically the units used are the same as those in which the source data is

24

presented. If for example one is modelling an experiment based on data which was

collected using kilograms per one hundred kilograms of soil, then these units would be

used throughout. The output will also be in these same units.

D) Locations by Parameter Designation:

TO,T1, LENGTH, I NTE R

CONC(l),CONC(l 4),CONC(2),CONC(6),CONC(1 5),CONC(l 6)

CF(1),CF(1 4),CF(2),CF(l 5),CF(l 6),CFTILL

EFFAC(l),EFFAC(2),EFFAC(l 5),EFFAC(l 6),EFSINK

CN(l 5),CN(1 6),CSTDEN,CSTSYM

FERNH4,FERN03

AER,TILL

CPER(1 5),CPER(l 6),CPER(1),CPER(1 4),CPER(2),CPER(6)

PER(l),PER(l 4),PER(2),PER(6),PER(8),PER(1 0),PER(l 1),PER(l 5),PER(l 6)

E) Definitions of Parameter Designations:

TO

T1

Initial time (time zero):This generally has the value zero, although it

can be set at other values if appropriate.

The start of the next timestep (time one) after time zero, the

difference (T1 -TO) between this number and time zero (both in

days) defines the duration of the timestep.

LENGTH

The length of the run in terms of total number of computational

timesteps.

INTER

The number of computational timesteps between output

expressions.

All the CONC parameters, which refer to the concentration of C in various pool,

are determined by the initial situation in the soil and by the units used. For example a

bog would have high values for CONC, while a sandy soil would have low values for this

parameter.

CONC(l)

CONC(l 4)

CONC(6)

CONC(2)

CONC(l 5)

CONC(l 6)

CF(1)

CF(14)

Concentration or quantity of pooll labile carbon.

Concentration or quantity of pooll resistant carbon.

Concentration or quantity of the humad pool's

labile carbon (tillage pool).

Concentration or quantity of the humad pool's resistant

carbon.

Concentration or quantity of residue labile carbon.

Concentration or quantity of residue resistant carbon.

The specific rate of decomposition for the microbial pool's

labile fraction. Suggested value: 0.332 (day-1).

The specific rate of decomposition for the microbial pool's

25

resistant fraction. Suggested value: 0.0404 (day-1)

CF(2)

The specific rate of decomposition for the humad pool's

resistant fraction. Suggested value: 0.006 (day-1).

CF(l 5)

The specific rate of decomposition for labile fraction of the

residue. Suggested value: 0.75 (day-1).

CF(1 6)

The specific rate of decomposition for the resistant fraction

of the residue. Suggested value: 0.02 (day-1).

CFTILL

The specific rate of decomposition for the labile fraction of

the humad pool. Suggested value: 0. 16 (day-1).

EFFAC(1)

The maximum efficiency factor for the recycling into pooll

of substances released by the decay of the microbial pool.

Suggested value: 0.6.

EFFAC(2)

The maximum efficiency factor for the recycling into the

microbial pool of substances released by the decay of the

humad and tillage pools. Suggested value:0.6.

EFFAC(l 5) The maximum efficiency factor for the uptake by the

microbial pool of substances from the labile portion of the

decayed residue. Suggested value: 0.6.

EFFAC(l 6) The maximum efficiency factor for the uptake by the

microbial pool of substances from the resistant portion of

the decayed residue. Suggested value: 0.6.

EFSINK

The maximum efficiency factor for the incorporation in the

humad pool of substances released by the decay of the

microbial pool. Suggested value: 0.2.

The carbon:nitrogen ratio of the residue is determined by the type of

residue being modelled. For example, dry straw would have a very high

carbon:nitrogen ratio, while freshly cut alfalfa would have a very low

carbon:nitrogen ratio. These values are readily available for most plant

residues, so suggested values are not given for them here.

CN(l 5)

CN(l 6)

CSTIDEN

CSTSYM

The carbon:nitrogen ratio of the labile fraction of the residue.

The carbon:nitrogen ratio of the resistant fraction of the

residue.

A proportionality constant relating units of carbon decayed

per unit of nitrogen lost through denitrification.

Suggested value: 25.0.

A proportionality constant relating units of carbon decayed per unit of

nitrogen fixed nonsymbiotically. Suggested value: 10.0 (this is an estimate

of a value which is largely unknown).

No suggested values are given for the following parameters since these represent

fertilizer additions and are determined by the situation modelled by the user.

FERNI-14

The concentration or quantity of the initial amount of

26

FERN03

nitrogen in the form of ammonium.

The concentration or quantity of the initial amount of

nitrogen in the form of nitrate.

The following parameteres are also determined by the type of situation the user wishes

to model, so no suggested values are given.

AER

This is the aeration factor which is decided by the degree of water

saturation of the soil and whether denitrification, nitrification or both will

occur (1 =nitrification, 2--denitrification, 3=both).

TILL

This factor tells the model whether or not tillage will occur during the

model run(l =tillage will occur during the first computational timestep).

In the parameters designating the degree and location of the tracer isotopes, the

users discretion is the key factor. Guided either by data from actual tracer experiments,

or by a desire to model such an experiment tracing particular C or N flows, the user

assigns certain fractions of tracer elements to selected pools using these parameters.

No values are suggested, and in many simple cases these parameters can simply be

ignored and given the value of zero.

CPER(1 5)

CPER(1 6)

CPER(1)

CPER(1 4)

CPER(2)

CPER(6)

PER(l)

PER(l 4)

PER(2)

PER(6)

PER(8)

PER(l 0)

PER(l 1)

The initial ratio of carbon 14 to total carbon in the labile

fraction of the residue.

The initial ratio of carbon 14 to total carbon in the resistant

fraction of the residue.

The initial ratio of carbon 14 to total carbon in the labile

fraction of the microbial pool.

The initial ratio of carbon 14 to total carbon in the resistant

fraction of pooll.

The initial ratio of carbon 14 to total carbon in the

resistant fraction of the humad pool.

The initial ratio of carbon 14 to total carbon in the labile

fraction of the humad pool.

The initial ratio of nitrogen 15 to total nitrogen in the

labile fraction of the microbial pool.

The initial ratio of nitrogen 15 to total nitrogen in the

resistant fraction of the microbial pool.

The initial ratio of nitrogen 15 to total nitrogen in the

resistant fraction of the humad pool.

The initial ratio of nitrogen 15 to total nitrogen in the

labile fraction of the humad pool.

The initial ratio of nitrogen 15 to total nitrogen in the

ammonium pool.

The initial ratio of nitrogen 15 to total nitrogen in the

dinitrogen pool (available through nonsymbiotic fixation).

The initial ratio of nitrogen 15 to total nitrogen in the nitrate

27

PER(l 5)

PER(l 6)

pool.

The initial ratio of nitrogen 15 to total nitrogen in the

labile fraction of the residue.

The initial ratio of nitrogen 15 to total nitrogen in the

resistant fraction of the residue.

F) Example of an NCDATA File:

0.,.1,100,10

.56,.44,2650.,0.,2500.,2500.

.332,.0404,.006,.75,.02,.16

.6,.6,.6,.6,.2

1000.,1000.,150.,10.

0.,200.

2.,1.

0.,0.,0.,0.,0.,0.,1.,0.,0.

3) NCOPUT Column Key

The NCOPUT file is the output from NCSOIL, it consists of series of columns.The

columns are divided into groups, each with a general title. Each column has a heading

identifying it with a particular output parameter, which is specific to the general catagory

in which it appears. For example; POOLI in the CUMUL-C02-C grouping refers to the

cumulative carbon dioxide release from the microbial pool, while POOLI in the

ORGANIC-C grouping refers to the amount of organic carbon present in the microbial

pool. The following list

gives the meanings of the headings, it is followed by a list of definitions of the group

titles, together these lists allow the identification of the output parameters.

A) Headings:

CARBON

C14

C02

C/N

CN

DAY

DENIT

EFFAC

N14

N15

NH4

The total amount of carbon in the system.

The total amount of labeled carbon in the system.

The amount or fraction of labeled carbon dioxide released

at each timestep.

The ratio of organic carbon to organic nitrogen .

The ratio of residue potentially available for

decomposition per day to the nitrogen available.

The timestep in units of days since the run began.

The total amount of nitrogen which has been denitrified at

each time step.

The actual efficiency factor for residue (labile and resistant)

decomposition.

The amount of this nitrogen isotope in the system.

The amount or fraction of this nitrogen isotope in the system.

The amount of nitrogen in the ammonium pool at

28

NH4+NO3

N03

NOSYMFIX

POOLI

POOLII

PI-LABI

PII-LABI

PI-NH4MI

PII-NH4MI

PI-RESI

PII-RESI

RESIDUES

RES-LABI

RES-NH4

RES-N03

RES-RESI

TOTAL

any given timestep.

The amount of nitrogen in both the ammonium and nitrate

pools at any given timestep.

The amount of nitrogen in the nitrate pool at any given

timestep.

The cumulative amount of nitrogen which was fixed

nonsymbiotically at any given timestep.

The microbial pool, including both its labile and resistant fractions.

The humad pool, including both its labile and resistant fractions.

The labile fraction of pool one.

The labile fraction of the second microbial pool.

The mineralized nitrogen from pool one.

The mineralized nitrogen from pool two.

The resistant fraction of the first microbial pool.

The resistant fraction of the second microbial pool.

The amount of carbon dioxide released as a result of residue

decomposition.

This refers to the amount of organic carbon in the labile

fraction of the residue.

Ammonium mineralized (>O) or immobilized (<O) from residues.

Nitrate immobilized (<O) from residues.

The amount of organic carbon present in the resistant fraction of

the residue.

The total amount of carbon released as carbon dioxide by the

system.

B) Group Titles:

INORGANIC-N

The nitrogen which is not in organic form (either NH4 or N03).

CUMUL-N

The cumulative transformation of nitrogen in the various pools.

CUMUL-C02-C

The cumulative amount of carbon lost as carbon dioxide from the

various pools.

ORGANIC-C

The carbon present in organic (not C02) form in the various pools.

MASS BALANCE

This group keeps track of all the carbon and nitrogen in the system

and insures that all of it is accounted for.

N 15 FRACTION

This is the fraction of N1 5 in the various pools.

N 15 CONTENT

The actual amount of N15 present in the various pools.

C1 4 CONTENT

The actual amount of C14 present in the various pools.

29

C14 FRACTION

The fraction of C14 in the various pools.

4) Running The Model On Cyber

The preceding portions of the appendix have dealt with the internal workings of

the NCSOIL program and NCDATA its data file. This section of the appendix deals with

the system on which this program runs. In order to run the program the user must be

able to log on the computer, access the program and order the computer to run it. In

addition the user must be able to modify the input data to suit the situation he or she

wishes to model. Finally the user should be able to retrieve the program's output and

render it into a meaningful form.

Before the user can log on the computer, a user number and password must be

obtained. At the same time it is a good idea to get two excellent references: the "XEDIT

Users Guide" and the "GUIDE TO CYBER INTERACTIVE COMPUTING". These may

be obtained from:

Academic Computing Services and Systems

Room 100

Lauderdale Computer Facility

2520 Broadway Dr.

Lauderdale 55113

Helpline (612) 626-5592

This part of the appendix is divided into four parts. The first part is an example of

what a session with the Cyber computer would look like. This example excludes the

portions of the sessions specific to the listing of files and the use of subprograms. It is

intended to give examples of logging on and off, and giving Cyber commands. This is

followed by a presentation of the basic commands needed to manipulate the general

operating system of Cyber. This system is called the "NOS" operating system, and all

subprograms are accessed from it.

Next, the first of these subprograms is discussed: the Xedit line editor. Xedit

allows the user to create and modify NCDATA data input files. It is accessed from the

main system but has a separate operating system with commands specific to it. These

commands are presented in a subsection of this portion of the appendix.

Another subprogram of interest is the MINITAB statistical package. Although it

has wide range of statistical abilities, only its use as a way to draw graphs will be

detailed here. Graphic output is often more intelligible than the columns of numbers

created by NCSOIL in the output file NCOPUT. For an in depth presentation of

MINITAB the user should consult the "MINITAB Student Handbook" (see reference

section).

30

A) Example of a Run on the Cyber Computer:

Having accessed the computer by calling it up and connecting a modem, the

session will proceed as follows (note computer reponses are in bold letters):

(user hits return key to initiate session)

UCC NETWORK UO. 1 PORT 1 H24

TO CONNECT TO MACHINE XX, TYPE C XX

WHERE XX IS CA, CB, OR ME.

*C CA

85/02/16 08.21.17. TERMINRL:44, P 40

UOFM CYBER 730 NOS 1.3 (06/13-CW).

FAMILY: ca

USER NUMBER: your user number

PASSWORD: your password

TERMINAL: 44 P 40/TTY

RECOUER/SYSTEM: (user hits return key)

old,ncdata

/xedit,ncdata

(at this point the user goes into the ncdata file and modifies it to create the

input parameters desired, and then goes back to the main operating system)

/old,ncsoil

/submit(ncsoil)

PASSWORD

your password

SUBMIT COMPLETE JOB NAME IS ROFIRWJ

(after waiting about two minutes the user can access the output)

old,ncoput

Anh

(the computer then shows the output)

old,nctab

minitab

(the user is transferred into the MINITAB subprogram while it generates

graphic output, and then returns to the main operating system using the "Quit"

command)

bye

ARC1234 LOG OFF 02/16/85

EFGH044 SRU

1.253 UNITS

(The session is now over and the user has been logged off).

31

B) A Brief NOS Tutorial

In order to run the NCSOIL program on the Cyber computer it is necessary to

know the overall system commands which tell the computer what to do. These

commands are part of the NOS control system. This system is based on the concept of

the "file". A file is a designated part of the computers memory which may contain data,

text or a program. It is best to visualize this as an actual file in order to keep track of the

meaning of the various commands. All commands are typed in and then followed by

hitting the return key. If a mistake is made the user can either backspace over it, or hit

the "DEL" or delete key, and the error is not transmitted to the computer.

To start the computing session the user must get the file he or she is interested

in from the computers memory. The files in memory are the "permanent" files. To work

with a particular file it needs to be made "local" to the user. This means that a copy of

the file is directly available to the user, while the original version of the file remains in

memory. To summon an existing permanent file the user types in the following

command:

old,filename

Where "filenamew is the name of the desired permanent file.

In the current instance the user would type in "old,NCSOIL", and NCSOI would

then be a local file available for use.

However, NCSOIL cannot be run by itself; it requires a data file of initial

parameters called NCDATA. If such a file doesn't exist it is necessary to create it. This

is done using the command:

32

new,filename

Command creates new file without using “old,filename”.

This creates a local file with the given name. The file is empty and to fill it the

user must stop giving the computer commands and enter the contents of the file. This is

done by leaving the command mode (after creating the new file) and entering the text

mode. While in text mode, entries are not regarded as commands but are placed in the

current filename. To enter text mode type in the command:

text

Once all the text has been entered the user can leave text mode and return to

command mode by holding down the control key and typing the letter "C". Now, in order

to save the current contents of the local file which has been created, the following

command is used:

save,filename

This takes the local file named and saves it as a permanent file in the computers

memory.

Errors often creep into text as it is being entered. In order to correct them it is

necessary to enter the text editor XEDIT. While not actually separate from the Cyber

system, Xedit can be regarded as a distinct subsystem with its own commands. To use

Xedit the file of interest must first be made local using the "old,filename" command. This

is followed by the command:

Xedit,filename

This puts the file under the control of the Xedit system with its distinct set of

commands (which are presented later in this section of the appendix). Xedit allows the

user to make alterations to the local file.

When all the modifications have been made the user returns to the NOS

command mode. Now the corrected version of NCDATA is available and will be called

automatically by NCSOIL.

33

The user is now ready to actually run NCSOIL. This is done by sending the file

off to Cyber's central processing unit as a job for Cyber to do. First NCSOIL is made

local using the "old" command. Then NCSOIL is sent off using the following command: ,

submit(NCSOIL)

When Cyber has accepted the job and is going to get around to it, Cyber will

repond with a message saying: SUBMIT COMPLETE JOB NAME IS ABCDEFG

The job name is an identifier assigned by Cyber so that the user can check on

the status of each particular job sent in. To do this the user calls a file called "Dayfile".

This is a record of all of the jobs submitted. When a user wishes to view the dayfile, she

or he makes it local and then uses an abbreviation for "List the file with No Header".

Typed in, it looks like this:

old,Dayfile

LNH

The computer then begins printing out the dayfile. If the file of interest has run, its

job name will appear at the top of the dayfile. In order to find out if the job ran

successfully the user looks for the following key lines:

LGO(OP=F)

STOP

34

If these lines appear then the job ran to a successful conclusion. Anything else,

especially including the words "error" or "job aborted" means the job was not successful.

The user should then examine the NCIDATA file to try to find the error which prevented

the completion of the job.

Once several jobs have been submitted, the dayfile recording all this activity

becomes quite long. In order not to have the whole file printed out after each job the

user can type the command:

Stop

This is done while the printout is occurring and stops it. At the end of the session

when all the jobs have been run, the user can clear the dayfile for future use by typing

in:

Purge,dayfile

This command can also be used to remove any other file which is designated

after the word "purge".

When it runs, NCSOIL creates two kinds of permanent output files which are

present under two filenames when the job is complete. These are the files: "NCOPUT"

which is conventional printout whose key appears earlier in the appendix, and NCTAB

which is output specially formated for use with the graphics package MINITAB (the use

of MINITAB is detafled later in this part of the appendix).

35

To view this output the procedure is the same as with the dayfile:

old,NCOPUT

LNH

MINITAB is like XEDIT, a subsystem which must be entered using the command:

MINITAB

Once a job has been run successfully the user may wish to change the input

parameters and see how this effects the system. If NCDATA is changed and the

NCSOIL is resubmitted it will replace all the data present in NCOPUT from the previous

run with the new data which has just been generated. To keep the original data it must

be given a new designation before the next job is submitted. This is done using the

following command:

change(newfilename=oldfilename)

The permanent file now has the new filename and the next job can be run

without losing the current output.

Finally when the user wishes to end the session and log off the Cyber he or she

simply types in:

Bye

NOS Commands in Brief

BYE

End the session, log off the computer.

CHANGE(new filename=oldfilename)

Rename file under a new designation, save it

as a permanent file under that designation.

LNH

Print out a listing of the current local file.

MINITAB

Enter the MINITAB subsystem.

NEW, filename

Create a local file called "filename".

OLD, filename

Get the local file called filename and make

it a local file.

PURGE, filename

Destroy the permanent file called "filename".

36

SAVE, filename

Save- as a permanent file called "filename".

STOP

Stop printing out the current file.

SUBMIT (filename) Send the file "filename " containing a program to the Cyber central

processing unit, to be run as a job.

TEXT

Enter text mode. All entries following this command are regarded

as text and not commands by the computer. To leave text mode

hold down the control key and type a "C".

XEDIT

Enter Xedit line editor subsystem.

C) A Brief XEDIT Tutorial:

Xedit is a subsystem which allows the user to create and modify the NCDATA

file. Xedit is a line editor, which means it moves through a file line by line, and that its

command structure is in terms of lines. Like NOS all commands are followed by the

return key. To enter Xedit one uses the NOS command stated previously:

Xedit,filename

This opens the Xedit subsystem with the named file as its subject ( note that the

file has to have been called using the NOS command "old,fi le name). Now the counter

for Xedit (which determines where it is in the file) is automatically set at the top of the

program. Assuming for the moment that the user is working on an existing file such as

NCDATA, the user may want to see the whole file listed out. To do this the user types:

Print *

This causes the printing of the rest of the file starting with the current line. If the

user only wants to see a few lines then "Print" is followed by a number (representing the

number of lines to be printed) rather than a "*".

Having looked over the file and noticed a place needing modification the user can

go directly to that place by using the "Locate" command which has the form:

Locate/string/

Where "string" is any group of characters which occur in the line of interest and

will identify it. Note that Xedit only searches through the file line by line until the end of

the file where it stops. If the desired line was above the current line, it won't be found.

For this reason it is often necessary to go back to the beginning or top, of the file. This is

done with the command:

Top

37

Assuming that the editor is now at the line which is to be changed, this can be

done using the command:

Modify

Type "modify" followed by return key before typing in changes.

This command is different from the previous commands in that it has two parts.

After the user types in "Modify" the computer prints out the line to be modified. Then the

user types characters under appropriate sections of the line which modify it. These

characters are:

#

^ string#

&

Delete the character above.

Insert the string of characters between the "^" and the “#” before the

character above the

Replace the character above with a blank.

Any other character will replace the character above it on the line being

changed.

An example of how these commands might be used is as follows. The computer

reponses are in the more bold print. Starting by moving the pointer to the top of the file:

Top

I think that I shall never see

Locate/billboard/

R billboard louey assa treee

Modify

A billboard lovey assa treee

^|# &

#

A billboard lovely as a tree

At times the user may wish to move around within the program without having to

start from the top and use the locate command. This can be done using the command:

Next n

Where "n" is the number of lines.

This command moves the pointer down the number of lines specified in the

command. In order to move up in the file use the same command followed by a

negative number.

So far we have been dealing with manipulating existing lines, but it is also

possible to add new lines. This is done by hitting the return key twice at the desired

point in the file. The computer will respond with the word "Input", and all further lines will

be regarded as text and not commands. To leave input mode again hit the return key

twice and the computer will respond with the word "Edit". It is now ready to receive

38

commands again. A common error is to enter input mode inadvertently and then wonder

in frustration why the computer isn't responding to the commands.

This brings us the the issue of removing errors. If an error has been typed but the

return key has not been hit, the error can be cancelled by hitting the "DEL" delete key. If

a whole line or lines need to be removed, the following command is used:

Delete/string/n

Where string is the set of characters identifying the offending line,

and "n" is the number of lines to be deleted. If a string of characters

is not specified, then Xedit deletes the next "n" lines.

Finally the user wishes to leave the Xedit subprogram. This can be done in

several ways. If the user simply wishes leave the program and keep the file just as it

was before she or he entered Xedit, then the appropriate command is:

Stop

However the user may wish to keep the original version of the permanent file and

also keep the new modified version of the file as a permanent file under a new name.

This is done by using the command:

Quit,fi lename,Save