Optical Fiber Sensing: Optca be Se s g: Sensing solutions from the

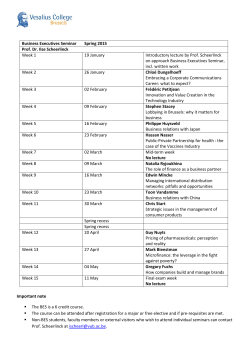

Optical Fiber Sensing: Opt ca be Se s g: Sensing solutions from the macro world to the micro world to the micro world Prof Gerald Farrell Prof. Gerald Farrell, Director, DIT Photonics Research Centre 8th April 2015 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Overview Optical fiber sensing in general Application A li ti areas Sensing solutions from macro to micro Futures directions and challenges 2 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Optical Sensing O Optical ti l Sensors S utilise tili light li ht tto measure/sense / a wide range of physical quantities o Strain, temperature, distance, humidity o Gas and liquid composition Optical Image sensors o Image sensing o Selected bio- and chemical- quantities q Optical fiber sensors use light but are based on glass or plastic optical fiber Not just about light transport – the fiber itself is the sensor MEMS CO2 sensor Bragg Grating Fiber Sensor 3 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Advantages g Electrical strain gauge rosette Wide variety of types, working on many different principles Singlemode fiber Advantages: • Many advantages inherited from fiber itself; • Low attenuation – long range; • Immunity to electromagnetic interference; • Not electrically conductive, usable with Fiber optic equivalent high voltage, in explosive or chemically aggressive environments; • Lightweight, small size; • High sensitivity; • Multiplexing possible – distributed sensing. A380 fuel tank sensors Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted 4 Wide variety of Application Areas Transport Bridges and Civil Structures Oil-Gas Exploration p Medical Bio-diagnostics Energy Systems Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Security Wide Range of Application Scales km Macro scale, m-km Medium scale, mm-m To provide solutions for a wide variety of application areas, sensors are needed for measurements from a nano/micro scale to a macro scale Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Micro scale scale, µm Nano scale, nm nm What types of Fiber based sensors are available? Fiber bend loss based devices Photonic Crystal Fibers Fiber interferometric structures Fiber Bragg and Long Period Gratings Fiber Hetrostructures such as SMS Liquid Crystal modified fibers Tapered fibers Periodically tapered fibers Micro- and Nano-Fiber Resonators Microfiber Couplers Surface Plasmon Resonance Devices Polarimetric fiber structures Surface modified structures, for example using electrospun fibres Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted 7 Variety of Fiber Sensing Solutions to match Scale Distributed sensors: Polarimetric, Brillouin km Macro scale, m-km Grating based sensors, FBGs and LPGs PCF based sensors, PCFIs Medium scale, mm-m Microfiber based Mi fib b d sensors, OMCs, Microresonators Micro scale scale, µm Microfiber + Nanoparticles, LSPR Nano scale, nm nm 8 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted km Macro scale Sensing m-km mm-m µm nm Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted nm Structural Health Monitoring – why do we need it? R il B Rail Bridge id collapse, ll D Dublin bli 2009 Composite Rudder failure Ai b A310 Airbus A310, 2005 Windmill blade failure, Illinois, 2010 I35W Bridge collapse, Minneapolis 2007 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted 10 SHM Sensing for Composite Materials Composite materials are replacing many traditional materials in many sectors Lightweight but very strong but still need SHM Embedding sensors creates a smart material ”aware” aware of its environment. Boeing g 787 Dreamliner construction Fibre Sensor embedded in Aerospace Composite Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted 11 Hybrid Sensing for Composites Simultaneous distributed measurement of strain, strain temperature & vibration and other parameters. Research on utlising two sensor types working together: FBG sensors combined with HB Polarimetric sensors Aim is to overcome the limitations of the individual sensor technologies Focus on aviation components under stress – struts, rotor blades etc. Project with WUT: Smart Sensors for Engineering Structures (SSES) Under carriage strut MATERA - ERA-NET Materials Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted 12 Strain and Temperature Results FBG and d Polarimetric P l i i Sensors S -31.75 -32.1 FBG sensor P l i t i sensor Polarimetric FBG sensor Polarimetric sensor -32.0 -31.70 Intensity dBm m Intensity dB Bm -31.9 -31.8 -31.7 -31.65 -31.60 -31.6 -31.55 -31.5 0 200 400 600 800 1000 1200 1400 1600 Applied Strain 1800 -31 31.50 50 20 25 30 35 40 45 50 55 60 65 70 Temperature C Change in intensity of the individual sensors with applied strain Change in intensity of the individual sensors with ith change h in i temperature t t A Photonic Crystal Fiber and Fiber Bragg Grating Based Hybrid Fiber Optic Sensor System”, IEEE Sensors Journal, January 2012 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Sensing for Magnetoreological Composites Magnetoreological (MR) composites have controllable mechanical properties Magnetic field can be used to control material stiffness and damping Useful for adaptive elastomer structures, eg shock absorbers for earthquake p protection Using optical sensing technology to provide strain feedback during curing and also in use under magnetic control Bridge Seismic Elastomer Bearing Bridge Seismic Shock absorbers 14 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Magnetoreological Cure Sensing Have demonstrated that PM-Sensors are superior to FBGs MR Sample PM-PCFs detect changes FBGs do not detect during curing 15 Ramakrishnan , Farrell et al - Monitoring curing of an MR – Electronics Letters 2013 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted km Medium Scale Sensing m-km mm-m µm nm Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted nm Optical Fiber Sensing for Surgical Instruments ■ Modern surgical techniques, techniques such a minimally invasive surgery (MIS) demand “smart” surgical instruments ■ Sensors needed to provide accurate force feedback to the surgeon ■ Adds a sense of touch for the surgeon Laproscopic or MIS Surgery g y Telerobotic Surgery Robotic Neurosurgery Orthopaedic O th di Surgery 17 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Optical Fiber Sensing for MIS Surgical Staplers ■ Surgical staplers and clip applicators allow a surgeon to join or close tissue during MIS ■ Biggest gg issue is failure of the clip p or staple p which causes complications for patient (8-9% of cases) ■ Challenges: - Need for very compact sensors - Temperature independence - Integration and calibration ■ Sensors types: - Minature FBGs - PCF based sensors Rajan, Farrell et al, IEEE Transactions on Biomedical Engineering, 2012 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Circular Stapler – multiple staples Clip Applicator 18 Photonic Crystal Fiber Interferometer sensorized MIS devices • Miniature (~50 µm) PCFI strain sensor using hollow core PCF. Sensorised jaws of a surgical clip applicator • High strain sensitivity sensitivity, no temperature compensation required. • Can be used to provide force feedback for laparoscopic devices during MIS procedures procedures. Ethicon laparoscopic clip applicator 50 µm Jaws (0.5 cm) Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted PCFI Micrograph 19 Performance of a PCFI sensorized i d MIS device d i 7 0 400 Strain sensitivity ~ 4.0 pm/ 6 wavele ength shift , nm 200 Strain, 600 800 1000 1200 1400 5 4 3 2 o Temp sensisitivty ~ 0.2 pm/ C 1 0 10 20 30 40 50 o Temperature, C 60 70 Strain & Temp Sensitivity “Photonic Crystal Fiber Strain Sensors for Laparoscopic Surgical Staplers”, Mathews and Farrell etc al, Photonics Global Conference (PGC), Singapore, Dec 2012 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Breath Sensor using an Infiltrated PCFI • Uses Agarose infiltrated photonic crystal fiber interferometer • Breath analysis application program for breath rate and pattern • High g mechanical stability y against g vibrations and air flow • Suitable for monitoring patients during an MRI scan Highlighted in Nature Photonics in February 2013 A miniature optical breathing sensor, Biomed. Opt. Express, 2012 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted km Micro scale Sensing scale Sensing m-km mm-m µm nm Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted nm Some Fiber Sensing Solutions for the Micro World Sensors include: • Micro-Fiber Resonators • Microfiber Couplers • Surface Plasmon Resonance Devices Periodically Tapered Fiber Micro Fiber Coupler Transition region Waist Transition region Half taper as a probe Bismuth silicate microsphere with full fiber taper for I/O Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted 23 Microfibers: a versatile sensing platform Standard optical p fiber with a diameter of 125 µm Microfiber with a diameter of 3 µm 24 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Why Microfibre based photonics for sensing? Evanescent field confined to within 10 µm of fiber centre centre, typical macro glass fiber is 125 µm in diameter Macro (traditional) fiber acts a “light light pipe”: pipe : Light guided in macro fiber sensors is immune to local environment Poor P solution l ti for f interaction i t ti with ith llocall environment i t for f many measurands. d What we need is a “light rail” – microfiber/nanowire Conventional optical fibers: Light guided inside the fiber Diameter = 125 μm Optical microfibers: Light guided outside of the fiber Typical diameters: 1-5 μm 25 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Microfiber Coupler Output (P3) Input Transition region g Waist Transition region g • Taper a pair of fibres twisted together to form a “Microfiber Microfiber Coupler” Coupler • Configuring a pair of microfibers as a coupler means we can use wavelength domain • Wavelength domain proven to be stable, precise and with the p potential for multiplexing p g of many y sensors Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted O t t (P4) Output Dumbell cross section. W kl ffused Weakly d fibers fib – greatest sensitivity to local environment Microfiber Coupler Based Labelfree Biosensor (Fibrinogen – Anti Fibrinogen) Experimental Broad Band Source Optical Spectrum Analyzer 0 Diameter ~ 2.5 (×2) μm Trans smission (dB B) -5 -10 -15 -20 PBS phosphate buffered saline Fibrinogen Anti-Fibrinogen -25 1550 1560 1570 1580 Wavelength (nm) Analyte captured Receptor immobilized Bare microfiber L. Bo, G. Farrell, et al, Optics Express, 2014. Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Probe type Microfiber Refractive Index Sensor • Hybrid H b id structure t t incorporates i t a fib fiber hetrostructure and a Photonic Crystal Fiber • • Relies of multimode interference to work, • Sensitivity 39.1 nm/RIU over an RI range of 1.33~1.38 V Very llow th thermall sensitivity iti it Dip wavele ength shifft (nm) • Tapered and then cleaved forming a probe type sensor 1548.0 1547.5 Measured data Linear fit 1547.0 1546.5 1546 0 1546.0 1.33 1.34 1.35 1.36 1.37 1.38 P. Wang, G. Brambilla, G. Farrell, et al, Optics Letters, 2014. Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Refractive index unit (RIU) Nanoscale Sensing km m-km Nanoparticle Enhanced Microfiber Sensors Microfiber Sensors mm-m µm nm nm 500 nm Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Overcoming Microfiber limitations • Decreasing the diameter of a microfiber increases the portion of light energy in the evanescent field outside the fiber • • Smaller microfibers with a diameter less than 1 µ µm offer better sensitivity y Problem is that as fiber diameter decreases, fiber becomes more fragile and difficult to manipulate and higher loss Local Environment Evanescent Field Distribution Microfiber Local Environment 30 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Metallic Au-Ag Nanoparticle Enhanced Microfiber • Evanescent E t field fi ld excites it localised surface plasmon resonance ((LSPR)) Evanescent field Nanoparticle • LSPR Resonance in the UV/visible region Microfibre • Resonance is sensitive to local environment • Au-Ag alloy nanoparticles combine best features of Au and Ag • Alloy mix allows for some tunability y Evanescent field ++ + + - Electron cloud + - - + + + 31 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Microfiber + Nanoparticle probe U-shaped U h d microfiber i fib (5 µm)) probe b samples formed, Each coated with various nanoparticle alloy mixes following surface preparation Higher Ag mixes show larger absorbances – stronger LSPR SEM Image 5 µm dia di A 25%Au75%Ag Abso orbance (AU U) 16 1.6 1.2 0.8 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted C: 75%Au25%Ag 0.4 0.0 350 1.3 -1.4 mm B 50%Au50%Ag 400 450 500 550 Wavelength (nm) 600 650 32 RI sensing using Microfiber + Nanoparticle probe U-probe used to measure RI Microfiber without nanoparticles has negligible response to RI All three nanoparticle alloy allo mixes show an increase in the LSPR peak absorbance as RI increases. Samples with higher Ag content t t exhibit hibit hi higher h sensitivities to RI The highest sensitivity is 44.918 AU/RIU 2.5 LS SPR absorbance (A AU) A' 25%Au75%Ag 20 2.0 1.5 B' 50%Au50%Ag 1.0 C' 75%Au25%Ag 0.5 1 33 1.33 1 34 1.34 1 35 1.35 1 36 1.36 Refractive index 33 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Conclusion Future Directions and Challenges for Optical Fiber Sensing Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Fiber sensors can meet the challenge of a wide variety of application scales! km Macro scale, m-km Medium scale, mm-m Micro scale scale, µm Nano scale, nm nm 35 Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Some Future Directions for Optical Fiber Sensing “Lab on a fiber” – multiparameter sensing g Sensors based on non-silica fibers Wearable sensors for medical applications Integration with microfluidics Ultra-high sensitivity sensors Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Pissadakis et al, microsphere resonators t iin a MOF 253 µm 27 µm 16 µm Rajan et al, Plastic Microfiber with an FBG Some Challenges for Optical Fiber Sensing Lack of sensor standards N Need d more llong tterm reliability li bilit data Dealing with sensor contamination Lower cost + compact + common feature interrogation systems Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Open ended PCFI Humidity Sensor FBG interrogation system Thank you Questions? email: gerald [email protected] farrell@dit ie Further details at: www.prc.dit.ie Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted Acknowledgements This publication has emanated from activity supported d iin part b by Science S i Foundation F d i Ireland (SFI) under the International Strategic Cooperation Award Grant Number SFI/13/ISCA/2845. Copyright © 2015, Prof. Gerald Farrell. Photonics Research Centre, Dublin Institute of Technology, Use for research or personal study is permitted This work was supported by the 111 project (B13015), att th (B13015) the H Harbin bi E Engineering i i U University i it and d also was supported by the National Natural Science Foundation of China (NSFC) under grants U1231201, 61275094

© Copyright 2026