NADH Oxidases described so far - Georgia Institute of Technology

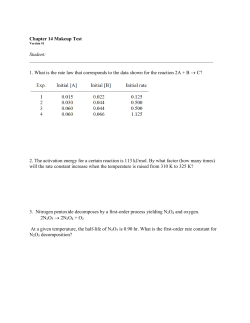

Biocatalysis for Carbohydrate Conversion Andreas S. Bommarius Georgia Institute of Technology ChBE, also CHEM Developing and Advancing Opportunities in the Bioeconomy Atlanta, GA; March 10-11, 2015 Paradigm shift in biotechnology process development Conventional Development Ideal Development Non-Ideal Biocatalyst Reaction Constraints Compromised “Ideal” Process Process Reaction Constraints Create the Ideal Biocatalyst S.G. Burton, D.A. Cowan, and J.M. Woodley, "The Search for the Ideal Biocatalyst", Nature Biotechnol. 2002, 20, 37-45 Perspective Pathway to developing a biocatalyst useful in synthesis has evolved A.S. Bommarius, J.K. Blum, and M.J. Abrahamson, Curr. Opin. Chem. Biol. 2011, 15, 194-200 Contents • Overview • Deconstruction of cellulose • Synthetic reactions with carbohydrates – Biomonomers • 1,3-propanediol (PDO) • Furandicarboxylic acid (FDCA) – Bulk Chemicals • Fructose from Glucose • Ascorbic acid Summary and Perspective • Process opportunities exist for cellulose, hemicellulose, and lignin • To succeed, products from renewables have to feature superior properties w.r.t. products from non-renewables, not just feature “Greenness” • Request: set the goal to RBI (i.e. the faculty) to develop process routes (incl. catalysts, solvents) – from defined raw materials to defined products, or – to products with defined properties. Major Components In Lignocellulosic Biomass H3CO HO OCH3OCH3 OCH3 OH OH O O OH OH O HO O HO O OH O O HO OH O O OH HO O HO O OH O OH OH O OH O O HO HO O OH O OH HO OH O HO OH O O OH O HO O OH O OH HO OH O OH O HO OH OH O O OH OH O O HO OH OH O OH O HO O HO OH O HO O OH OH O OH OH O OH O O HO OH OH O O HO OH OH O O HO O OH OH O HO OH OH O O O O OH OH O HO HO OH HO O OH OH O OH O O HO OH OH HO OH H3CO OCH3 O HO HO O O O HO O OH OH OH O OH O OH O OCH3OCH3 Hemicellulose: 23-32% Long chains of beta-linked glucose Semicrystalline structure O OH O OCH3 OH O OCH3 OH HO OH H3CO OCH3 O HO O HO Complex network of aromatic compounds High energy content Treasure trove of novel chemistry OH OCH3 Cellulose: 38-50% O O Lignin: 15-25% A collection of 5- and 6-carbon sugars linked together in long, substituted chains- branched Xylose, arabinose, glucose, mannose and galactose H3CO O OCH3 O OH OH O OH OH O HO HO O HO OH O OH HO OH O OH O O OH OH O O HO OH O HO OH O OH OH O OH OH O HO O HO OH O OH OH O OH J.D. McMillan, NREL MI Pretreatment on Lignocelluloses Mechanical mixture of Avicel and lignin (1:1 w/w) MI Ctrl 100 Temp: 25°C Time: 5 min MI: 100% 1-methylimidazole m.p. b.p. MI - 6oC 198oC Percentage lignin dissolved 90 80 70 60 50 40 30 20 SBL SEB 10 • MI – efficient delignifier • Extract lignin without dissolving, degrading or altering cellulose crystal structure Y. Kang et al., Biotechnol. Progr. 2015, 31, 25-34 SEWS SELP 0 0 20 40 60 80 100 120 Solid loading (g/L) Bagasse (SEB) and Wheat straw (SEWS) provided by Dr. G. Zacchi New PSE fellowship recipient: Thomas Kwok Cellobiohydrolase is a molecular machine Cellobiohydrolase (CBH, exo-glucanase, E.C. 3.2.1.x) consists of several domains that help to pre-organize the cellulose chain; some of the major issues are: - kinetics on a heterogeneous surface, and - processivity: number of glucose/cellobiose units cleaved during a binding event Cellulose-binding domain (CBD) U.S. Department of Energy Genome Programs (http://genomics.energy.gov) Catalytic domain Cellulase attack on cellulose Cellobiohydrolase I acting on cellulose • Heterogeneous biocatalysis Source: NREL (www.nrel.gov) 1. Adsorption 2. Find chainend end Find chain 3. E:S complex (thread into tunnel) 4. Hydrolysis (bond cleavage, expulsion, de-crystallization) Beckham GT et al., J. Phys. Chem. B, 2011, 115, 4118–4127 Bansal P et al., Biotechnology Advances, 2009, 27, 833-848 Rate slowdown along conversion • Rate slow-down is not simply due to substrate depletion • Importance of rate-order dX/dt = [Enzymes cleaving the β-glycosidic bond]*k dX/dt = k*[Eadsorbed,active]*S dX/dt = k*[Eadsorbed,active]*So(1-X) If no rate hindrances, dX/dt ~(1-X) • Crystallinity influences the order of the reaction 0 -2.5 -2 -1.5 -1 -0.5 -2 -4 -6 0 ln(dX/dt) -3 -8 -10 -12 ln(1-X) Apparent first order reaction with amorphous cellulose 10 No apparent rate order with crystalline cellulose (Avicel®) Experimental results 3.5 Normalized parameter value Rate (glucose in 10 min., mg/mL) • Restart rates account for most of the rate reduction, higher restart rates – the remainder is attributed to clogging • Hydrolysability (α), Kad decrease with conversion, [E]ads,max does not vary strongly, reactivity (k) no noticeable trend 3 2.5 Due to clogging Restart 2 1.5 Uninterrupted 1 0.5 0 0 20 40 60 80 100 Conversion (%) Hydrolysability 1.4 Kad [E]ads,max 1.2 Reactivity (k) 1 0.8 0.6 0.4 0.2 0 0 20 40 60 80 Conversion (%) 11 P. Bansal, et al., Bioresour Technol., 2012, 107, 243-250 Kinetic studies: summary Factors involved in determining the rate rate = k*[Eads,active]*So(1-X) (So – initial substrate conc.) rate = k*[Eads]*f*So(1-X) Total cellulose Accessible Hydrolysable Accessible/total ≡ [E]ads,max Hydrolysable/Accessible = α Rate/([E]ads,active) = k [E]ads,active/[E]ads = f f = 1 or α/y, where y = [E]ads/[E]ads,max Ratio of accessible to total cellulose decreases (adsorption studies) Productive adsorption - fraction of hydrolyzable cellulose Unproductive adsorption: obstacles, improper orientation of cellulose chain, exhaustion of reactive sites, etc. Cause cannot be explicitly measured or determined but productive adsorption related to hydrolyzability Intrinsic reactivity decreases with conversion P. Bansal, et al., Bioresour Technol., 2012, 107, 243-250 12 Top Value Added Chemicals from Biomass (2004 DOE report ) Bio Process for Soronatm: an example of both Metabolic Engineering and Biocatalysis OH HO HO O OPO3= Gene 1 OH HO O OH HO OH OPO3= Gene 2 HO Glucose OH Gene 3 O HO O O Gene 4 HO O n O 3GT OH 3G “T” OH Competition between chemical and biological route on novel polymer component: 1,3-propanediol acrolein ethylene oxide H2O, [H2] CO, H2 Shell process Degussa/Dupont process 1,3-propanediol E. coli glucose Dupont/Genencor process Glucose Glycerol Yeast PDO Bacterium DuPont Soronatm Insert Genes in Microbe Grow “Bugs” O ( --0-CH 2-CH2-CH2-0-C-1,3 Propanediol 3G Process microbes, separate product, purify, polymerize and form into end-use O ) ---C-- Terephthalate T Propanediol (PDO) from Cornstarch credit: Ray Miller, Dupont 2,5-FDCA (2,5-furandicarboxylic acid): building block for biopolymers 2,5-FDCA is a building block for polyethylene furanoate (PEF) or polypropylene furanoate (PPF) polyesters from renewables Poly(ethylene terephthalate) vs. poly(ethylene furanoate) O O O O O O O O O n PET Plastic • Petroleum-based • Food packaging (e.g., soda and water bottles) • Textiles (e.g., polyester) • 19.1 Megatons by 2017 Smithers Pira organization. 2012. n PEF Plastic • Bio-based • From Hydroxymethylfurfural (HMF) • Avantium (YXY), Bird Engineering (Netherlands) • Material properties superior to those of PET Burgess, et al. Macromolecules 2014. dx.doi.org/10.1021/ma5000199 Survey of routes to FDCA Glucose ↔ Harrison B. Rose Georgia Institute of Technology Hydroxymethylfurfural oxidase (HMFO) HFMO is a very new enzyme - Flavoprotein - O2-dependent W.P. Dijkman, ACS Catalysis 2015, 5, 1833-39 Food: glucose isomerase (GI), the commercially most important biocatalyst (!?) E.C. 5.3.1.5. Tetramer, composed of two dimers Subunit: 43 kDa Mg catalytically essential, also requirement for Co; Mg/Ca-ratio critical for proper activity Found originally as a xylose isomerase Example of a Sub-optimal Process NaOH Starch α-amylase breaks starch into 10-13 sugar units HCl Slurry (40% solid) Liquefaction pH 3.5-4.2 Glucoamylase Breaks into glucose monomers Requires: pH 6.0-6.2, Ca++ Saccharification Thermo-tolerant: 105°C Short Step 95 °C 1-2 hr Requires: pH 4.2-4.5 NaOH Glucose Isomerase Converts glucose to fructose Isomerization Chrom. Requires: pH 7.8 Enrichment $$$$ 42% Fructose 90% Fructose Crabb and Shetty. (1999). Curr Opinion Micro 2:252-256 Final Product: 55% Fructose A More Efficient Process NaOH X Starch α-amylase breaks starch into 10-13 sugar units Slurry (40% solid) HCl X Liquefaction pH 3.5-4.2 Glucoamylase Breaks into glucose monomers Requires: pH 6.0-6.2, Ca++ Saccharification Thermo-tolerant: 105°C Short Step 95 °C 1-2 hr Requires: pH 4.2-4.5 NaOH X Glucose Isomerase Converts glucose to fructose Isomerization Requires: pH 7.8 X Chrom. ______________________________ Enrichment $$$$ 42% Fructose 90% Fructose Final Product: 55% Fructose Fine chemicals, vitamins: Process routes to ascorbic acid Reichstein-Grüssner synthesis Sorbitol Fermentation Glucose Fermentation D-Glucose Hydrogenation D-Sorbitol Fermentation L-Sorbose Acetonization Diacetone-L-sorbose Oxidation/Hydrolysis Fermentation L-Sorbose Fermentation One step Process Fermentation 2-keto-L-gulonic Acid Esterification Methyl 2-keto-L-gulonic Acid Lactonization Ascorbic Acid Chemical Processing Technology Ascorbic Acid Chotani, G. et al. , Biochimica et Biophysica Acta 1543 (2000) 434-455 Process routes to ascorbic acid Table 20.3: Step Features of the steps in the Reichstein-Grüssner synthesis Yield cycle time (h); T,p, Work-up steps (%) cat, solvent Hydrogenation 95 2; 140°C, 80-125 bar; hot filtration, ion Ra-Ni, H2O/MeOH exchange, filtration Sorbitol 90 24; 30°C, 2 atm pH 5- centrifugation, oxidation deionization, 6 → 2; H2O crystallization 24; 30°C,135°C /3 Acetonization 85 2x distillation, Torr; acetone filtration, vac. /H2SO4, ether Distillation Oxidation 90 6; 50°C; pH H2O, Precipitation, acid, acetone; Pd/C filtration, drying Hydrolysis/ 85 2; 100°C; pH 2: distillation, rerearrangement HCl/MeOH, ClHC, crystallization, EtOH evaporation ClHC: chlorinated hydrocarbon [S] Biggest (g/L) challenges 200 Sterility & 2 atm O2 requ.; Ni tank material toxic 50 N2/CO2-atm required Current state of affairs : One-step biological production of 2-keto-L-gulonic acid (2-KLG) E1 D-Glucose E2 Gluconic Acid 2-keto-D-Gulonic Acid E1- glucose dehydrogenase E2- gluconic acid dehydrogenase E3- 2-keto-D-gluconic acid dehydrogenase E4- 2,5-diketo-D-gluconic acid reductase E3 2,5-diketo-D-Gulonic Acid E4 2-keto-L-Gulonic Acid (2-KLG) 2-KLG Recovery via Crystallization Esterification/Lactonization Recovery Ascorbic Acid Chotani, G., Biochimica et Biophysica Acta 1543 (2000) 434-455 Messages From This Presentation [Andreas Bommarius] • Possible applications of the insights/techniques/ findings/opportunities in this presentation – Lowering cost of clean raw materials (glucose, xylose) – Combine use of chemo/bio/catalysis to innovative products • Barriers and challenges to success – Cellulose hydrolysis to glucose still too expensive – Catalyses compartmentalized, unoptimized for $2-10/kg products • Additional research opportunities – (ligno)cellulose structure, cellulase kinetics – Catalyses in cascades and in benign, mostly aqueous solvents

© Copyright 2026