Using electric fencing to control winter stock feeding

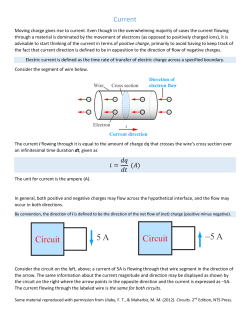

Power Fencing for Swath Grazing Since cattle standing in deep snow are usually poorly grounded, a 2 wire Power Fence is needed when swath grazing. The 2 wires, one hot and one ground wire, should be 12 inches apart. One–wire fences will work in the fall, but quickly lose effectiveness as the ground freezes. gives the greatest shock. The Turbo Horse Rope (#62257), EquiBraid (#62174) and Orange Turbo Wire (#62066) are specifically designed for portable fencing and will be far easier to handle than high tensile wire. Putting flags on the wire may be necessary for the first day or two to train the stock. Although the fence is portable, the ground rods will have to be permanently installed. Ground the wires of a conventional fence running along one side of the swathed field with a Ground Stake. Connect the ground wire from the feed fence to this grounded fence. Offset insulators such as Gallagher Offset Bracket with Pinlock Insulator (#65905 ) or Drive In Offset Bracket with Pinlock Insulator (#66205) can be used on the same fence to carry a hot wire. Don’t put the hot wire on regular post insulators fitted to the old fence, because the barbed or woven wire will short to it in the wind and snow. For quick and easy portability, Gallagher Pigtail Treadins (#64213) are ideal. Use an extra Screw–On Rod Insulator (#65514) for the second wire or use Steel Multiwire Treadins ( #64253). An alternative post system that is fairly easy to drive into the ground consists of 1/2" or 5/8" re–bar metal posts, 4 to 5 feet long, with good quality Screw–On Rod Insulators (#65514). When moving steel posts it's usually much easier to drive them in the centre of a new swath where the ground has been insulated by the swath. The exposed ground between the swaths will be the first to freeze and more difficult to drive the posts into. Highly conductive Turbo Horse Rope ( #62257 ), EquiBraid (#62174) or Orange Turbo Wire (#62066) Lastly, consider getting a SmartFix Fault Finder (#50900) or a Digital Volt Meter( #50301) for sorting out problems quickly and accurately – it can be considered ‘first aid’ for an electric fence. Pigtail Treadin with Screw–On Rod Insulators with For years, electric fencing has been used to control winter livestock feeding, greatly reducing feeding time, tractor use and feed waste. Success with this type of fence requires good construction, proper equipment and a basic understanding of how the fence works. It is often noted in winter that livestock don’t have the same respect for the electric fence that held them back all summer. Frost turns normally conductive soil into a very poor conductor of the electric current returning through the soil to the energizer’s ground rods. The frozen soil creates a poor circuit and little or no shock is felt by livestock touching hot wires. Ground Retur n System Return To solve this problem, Gallagher recommends the use of a ground return system. Connect one of the non–hot fence wires to the Ground Stakes (Ground Stake Kit #87901). Position the non–hot wire on the fence so the livestock touch both a hot wire and a non–hot wire at the same time. These wires should be placed a maximum of 12 inches apart. A complete circuit is made when the animal touches both wires and the maximum shock is felt, regardless of soil conductivity conditions. Ground Stake (6 ft galvanized) connected to old barbed wires or woven wires Swath Hot Highly conductive Orange Turbo Wire, EquiBraid or Turbo Horse Rope CONTROLLING WINTER CATTLE FEEDING Electron flow in ground return wire fence in dry or frozen conditions. + + Grounded Wire Hot High Tensile Wire Offset insulators on existing barbed wire or woven wire fence (50 ft spacing) Power Fencing Systems • 1-800-265-3150 Electron flow in all live system in damp conditions. Power Fencing The Ground Stakes used in the ground return system can be the same ones used by the energizer or separate ones can be installed on the fence line. Install the Ground Stakes before the soil gets too frozen. Energizer Grounding In order to get the full shock out of an energizer, it is important to have an adequate number of galvanized ground rods. Six foot long galvanized Ground Stakes reach mineral soil below the frost line and will not rust. Use at least one Ground Stake for every 2 joules of stored energy. A Gallagher M800, with about 8 joules of stored energy, needs at least 4 ground stakes. Space them 10 to 12 feet apart, clamped and wired together. Avoid non– galvanized metal components to eliminate electrolysis corrosion. Choosing an Energizer Large output energizers such as the MBX2500, MBX1500, MR2500, M1800, M800, B1600, B1200 and B600 are very effective in winter fencing. They have extra ‘kick’ (over 5 joules of energy) in their hot wire and are ideal for controlling feeding of hay or silage. A shock from one of these energizers is memorable enough that livestock seldom test the fence. A ground return wire may be needed in severe frost conditions or when livestock are standing in deep snow. The power or ‘kick’ of the electrical pulse the animal feels depends on: • the capabilities of the energizer: the higher the joule rating, the greater the shock, assuming that the energizer and fence are correctly installed. • the ability of the full pulse to complete the circuit: the average pulse lasts only 0.0003 of a second, so for high energy to be transmitted in this short time, the whole system must be well constructed and maintained. Low power, little into memory box Power Fencing Systems • 1-800-265-3150 High power, plenty into memory box 6JWFEED – 11/04 Hot Wire Round Bale Feeding Hot wire round bale feeding is the most common hot wire winter feeder, and is easy to set up and maintain. Bales are placed in straight rows between 2 parallel electric fences. The fences are made of 1 or 2 high conductive wires on post insulators. The bales should be on their sides with round sides touching, and the flat side of the bales forming a continuous feeding surface facing the animals.Orange Fibreglass Rods (#81830), 3/8" x 5 ft, with Screw–On Rod Insulators (#65514) are pushed into the bales every 30 feet across the feed face. A hot Gallagher Orange Turbo Wire (#62066), Gallagher EquiBraid (#62174), or Gallagher Turbo Horse Rope (#62257) is suspended by these rods. The wire is powered from the parallel electric fence using Insulated Gate Handles (#63930 or #68910) at each end. Overhead view of typical hot wire bale feeding yard. Livestock feed either over or under the hot wire until they can’t comfortably reach any more hay. The rods holding the hot wire are pushed further into the bales daily to allow feeding to continue. The feed wire should be set low enough to encourage livestock to eat the upper part of the Orange Turbo Wire or Turbo Horse Rope (do not use regular Polywire) bale face first. If the lower hay face is eaten first, the bales could topple forward, dropping the wire to the ground, and allowing the cattle to overeat and/or trample the hay. In general: • Feeding chores involve pushing the rods further into the bales and picking up and resetting any that have been pulled out. There is very little feed waste if the cattle are forced to eat hay lying under the hot wire, before the wire is set closer to the feed face. • Cold weather tractor feeding is practically eliminated. • Good and poor quality hay can be mixed in rows, or entire rows can be made up of different hay quality, greenfeed, etc. When setting bales out to build the feeder, avoid placing spoiled bale bottoms towards the feed face, or the cattle will eat around those bales. • Separate feeding areas can be set up for bulls, heifers, etc. or both ends of a bale group can be used for feeding at the same time. • There are fewer leg problems if plastic baler twine is removed from bales when they are set in place in the feed yard. Sisal twine is sometimes left on bales. • Allowing 1-1/2 to 2 feet per cow of offered feed face width greatly reduces competition and wire damage in front of bales. • Set out enough hay for the coldest part of the feeding season (e.g. mid–Nov. to mid–March). Alternate feeding areas may be needed during thawing weather in early spring, as the ground in front of the feed wire may get too soft. Bale feeders or hay rolled out on the pasture are possible alternatives. • Install a ground return wire on the feed yard fence before cold weather arrives, so that a second, grounded feed wire can be used with the hot wire if necessary. • For the best shock use high conductive wire such as Gallagher Orange Turbo Wire (#62066), Gallagher EquiBraid (#62174), or Turbo Horse Rope (#62257 ) for the feed wires. • In very cold weather move the feed wire closer to hay twice daily to allow more intake. Hot Wire Silage Feeding + Insulated Gate Handle Hot 3/8" (10 mm) Orange Fibreglass Rod, 5 ft long with Screw–On Rod Insulator Feeding system if cattle will respect single hot strand Silage can also be fed out using the same techniques. If a bunker silo is used, often support rods are not needed because the face distance is short enough for the wire to span right across. At least 6 inches of silage must be eaten each day to eliminate spoilage. Because of the height of the silage in a bunker silo, undercutting is a concern. It is often necessary to use equipment to break down the top of the face to allow cattle access to the silage. Power Fencing Systems • 1-800-265-3150 Hot Wire Hot Wire Grounded Wire Grounded Wire Feeding system if cattle need Ground Return System to respect fence Eat back top face first Hot Wire Round Bale Feeding - Star ting Out Starting Day 1 – To introduce cattle to the hot wire feeder, first remove all other feed sources. Set the feed wire a maximum of 1 foot off the ground and almost touching the feed face. By the end of the day, all animals should have investigated the bales and eaten some hay. Wire set low Day 2 – Pull the rods out of the bales and move the feed wire up to about 1/3 of the bale height from the ground. It should be out about 1 foot from the feed face. Ensure that there is good power on the feed wire. The cattle should eat above the feed wire until the top 1/2 of the bale face is eaten. Move the wire up so the cattle then eat below it. If the bottom part of the bale is eaten first, the bale will tip forward. This method will give a fairly even top to bottom eating pattern and let the cattle get used to how far they can reach over the wire. It will also help to determine how far out the feed wire should be from the bales for one day’s feeding. Longer 5 ft fibreglass rod reaches next row of bales Move wire up to eat bottom Day 3 and on – There is likely one wire height that will allow even feeding of the bale face. Try setting the wire at a little under 1/2 the bale height and adjust the height as necessary. Note: Any untrampled hay lying under the feed wire should be cleaned up by the cattle before the feed wire is set closer to the bale face. The livestock will soon eat it up if they are hungry and can’t reach any new hay. This will save feed since this hay is usually lost. Two different groups can be fed from one bale pile Power Fencing Systems • 1-800-265-3150

© Copyright 2026