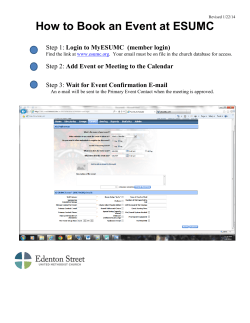

How to Use the Front Panel and Console