how to combat widespread auto parts counterfeiting FoCus on AFtermArket

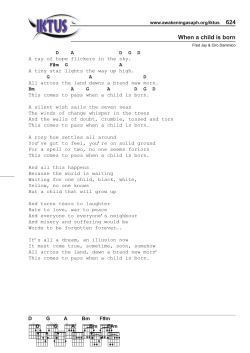

focus on aftermarket How to combat widespread auto parts counterfeiting By Pradip Shroff, President - HOMAI In 1872, inventor Elijah McCoy (Figure 1) patented a lubricating system designed to prevent overheating and seizing on steam engines. His lubricants worked extremely well, saving the shipping lines and railroads lots of money. The success and popularity of McCoy’s device soon brought many copies, which cost far less but didn’t work nearly as well. These fakes created costly problems for purchasers, who believed they were saving the money. Those who wanted to use a genuine product to ensure quality and dependability asked for McCoy’s 58 MOTORINDIA l July 2012 product by name. Thus was born the phrase “the Real McCoy.” The story that started in 1872 still exists today in a much bigger form of automotive piracy. The automobile sector across the globe is currently under grave attack from the counterfeit market. According to a survey conducted by the Motor and Equipment Manufacturers Association (MEMA), the global automotive industry loses $12 billion to counterfeiting. The Indian scene The automotive components sector in India has grown rapidly in the last decade and was estimated at INR 990 billion ($22 billion) in FY10. While there has been an increase in genuine market, the counterfeit market also grows parallel. In India it was started in 1980s when counterfeiting became first visible threat to automotive component businesses. As a result of sophisticated global economy, coupled with easy access to technological advances, very few product lines are able to escape the reach of counterfeiters. In the automotive components sector, various auto components in the aftermarket are counterfeited on a massive scale. Products such as filters, spark plugs and brake pads, bearings, piston and piston rings, etc., tend to be more prone to counterfeiting than others (see Table 1). In India, the problem is acute because of various factors such as: l The growing illegal manufacturing due to shortcoming of existing legislation and easy availability of material from China to produce/ make counterfeit auto components l Inadequate surveillance efforts by the brand owner to identify counterfeit products and to motivate/ involve sales and distribution resources to stop counterfeit products entering the supply chain from the manufacturer to the consumer l Tampering/re-packaging: Counterfeit automotive components entering the supply chain through local manufacturing, import from China Fig. 1: Elijah McCoy focus on aftermarket Table 1: Most commonly counterfeited parts and accessories Engine & exhaust Suspension and Body and Electrical braking structural components Oil filters Steering arms Sheet metals Alternators spares Air filters Tie rods Bumpers Head lamps Distributor caps Brakes Windshields Tail lamps Fuel filters Brake linings Wipers Coolant and transmission fluids Starter motor spares Bearings Oil pumps Water pumps Spark plugs Piston and piston rings Lubricants Sealing rings Source: ACMA / FICCI in the form of fake packaging or in original packaging sourced from mechanics or service stations l Higher margins: Compared to a genuine auto component, a counterfeiter earns 35-50 per cent on selling counterfeit car parts, while for others, this can be 55-75 per cent. l Lack of consumer education to identify authentic parts and realise the ill-effects of counterfeit parts l Supply constraints: Lack of easy availability of genuine parts for older variants of vehicles, and sometimes even for new models, leads to counterfeit sales. This may either be a supply constraint at the manufacturer’s end or a strategy at the distributor level to achieve high margins. l Lack of tools for law enforcement According to the ACMA White Paper, “Legislative Improvement to Combat Counterfeit Auto Components”, released in February 2011, the counterfeit trade volume is estimated at INR 247.5 ($5.5 billion) and accounts for 35 per cent of the aftermarket in India. Counterfeit auto component prod- ucts affect the entire society, manufacturers as well as the Government. Poor product quality can lead to serious accidents and sometimes to loss of lives. According to ACMA, the use of counterfeit products resulted in around 25,400 deaths and more than 93,000 serious injuries during 2009. In India, the automotive component sector provides direct or indirect employment to more than eight million people. Counterfeit auto parts can harm manufacturers by leading to: l Loss of revenue: Counterfeiting, tampering and diversion of sales are made at the direct expense of auto component manufacturers who make huge investments on development and promotion of their products. l Liability: The manufacturer can face potentially crippling law suits as incidents of counterfeiting, tampering and diversion, leading to accidental cases/health. l Brand integrity: While poor quality fakes damage the image of the original equipment manufacturer and endanger the lives of vehicle occupants, highly accomplished pirated products deprive manufacturers, who invest a lot of money in research and development, of their legitimate earnings. It is also relevant to note that sales of counterfeit parts clinically affect the reputation and goodwill of manufacturers. Counterfeit auto parts can harm the Government by leading to: l Loss of revenue: Sales of counterfeit or diverted products bypass traditional channels, thereby depriving the Government of tax revenue (see Figure 2). l Funding of criminal enterprises: The people who benefit most from counterfeiting are criminals who then use their proceeds to fund other criminal activity or to further their own enterprises. What the brand owners can do? Fig. 2: Loss of revenue to Government due to automotive component counterfeiting Financial year 2010 Value Total market for auto components INR 990 billion (US$ 22 billion) Share of aftermarket 25% Value of aftermarket INR 247.5 billion (US$5.5 billion) Share of counterfeit components 35% Value of counterfeits INR 87 billion (US$ 1.9 billion) Excise duty 10% Other taxes 15% Loss to Government* INR 22 billion (US $ 496 million) MOTORINDIA l July 2012 59 focus on aftermarket Fig. 3: Integrated holistic brand protection strategy Several studies have been done to measure the impact of the problem, but the suggested solution has been mainly to enhance effectiveness of law enforcement. It is important that a holistic solution is developed in this fight. The solution to this evergrowing menace lies at the very core of the product, i.e., a dire need to create an end-to-end holistic brand protection strategy. This strategy can be broken into various stages (Figure 3). As a first step, every CEO or brand owner should take the responsibility of brand attack and make Brand Risk Management (BRM) an intrinsic part of his business plan, review and report. The team may comprise the CEO/brand owner, brand managers, head of marketing, product development, sales, logistic, packaging, manufacturing or outside consultant accountable for the brand. The idea is to curb the penetration of counterfeits across levels. The team can periodically review the BRM by analyzing various issues like product categories and markets, buyer profiles and supply chain management and SWOT analysis of the counterfeiters. Making customized and integrated solution can be done by enhancing the participation of co-opting consumers or channel partners and by conducting verification, raids or ensuring strong law enforcement. For emphatic use of technology (Figure 4), have a secure, anti-counterfeiting device comprising overt, covert and forensic security features like security hologram seals and labels, tamper evident security films and Fig. 4: Emphatic use of technology by Bosch and Mercedes-Benz 60 MOTORINDIA l July 2012 light-sensitive ink designs. While there are a number of technologies available in the market, it is advisable to choose the smart one and at the right time while keeping track of some basic guidelines like: • Finding a vendor who can provide you overt as well as covert technologies as it is important to select a solution using multiple technologies. • Seeking help from an established trade association to select ethical vendor, best practices and resources to fight counterfeiting. • Selecting the technology in terms of the difficulty to copy/ tamper evidence posed by it (preferably patented), uniqueness, availability of suppliers, identifiable and user-friendliness. • Solutions should also have feasibility of being integrated with the automated production/packaging line, if required, especially where the volumes are very large • Try to combine low and high security elements to enhance protection, for example, by integrating sequential or unique numbers in the solution. “Brand Risk Management” should be treated as a crucial part of risk management under the focus on aftermarket direct responsibility of the board of directors/brand owners. The vision and mission statement of the company should be communicated to all the stakeholders and customers. This can be done by putting the information on the company’s corporate website, including it in the annual report or circulating it via intranet in the form of a document or video. (Companies like Mercedes Benz have a section on their website which defines their steps towards product protection). As for monitoring and developing an intellectual property strategy, the technology solution can be helpful in identifying and authenticating the original from the counterfeit. It is however very important that a planned surveillance program be in place to constantly monitor that there is no infringement. Equally important when an infringement is seen is that immediate action is taken so that the guilty is punished and the others sitting on the “fence” deterred. The new ISO 12931 is in the final stage and will soon be published. It will be a very useful document for anyone who wants to follow the globally accepted standards and approach to fighting against the counterfeit. The ISO document can be seen on http://www.iso.org/iso/catalogue_detail?csnumber=5221. While the counterfeit parts trade has dramatically increased in volume, tackling counterfeits is not impossible. This is a problem that needs to be addressed quickly and decisively. Ideally, as a first move, more effective partnerships should be built between law enforcement agencies and the private sector with focus on intelligence sharing, awareness and product identification training. Manufacturers should create a team that focuses on anti-counterfeiting strategy. Selection of the right anti-counterfeiting strategy is very important. However, involvement of all segments of the automotive and heavy-duty industries is essential to ensure the project success. w MOTORINDIA l July 2012 61

© Copyright 2026