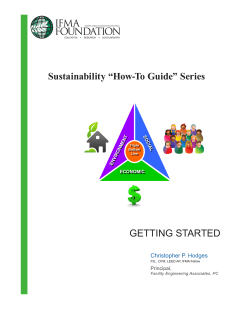

Sustainability “How-To Guide” Series A Comprehensive Guide to Water Conservation: