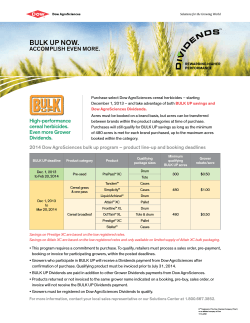

333333333 How to