How to fit a flowmeter, transmitter to an application

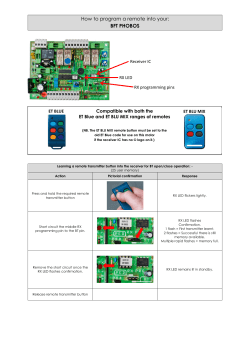

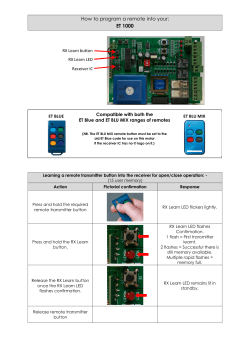

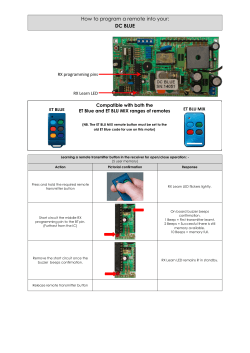

FEBRUARY 2003 Application & Product News for the Process Control Engineer How to fit a flowmeter, transmitter to an application An energy reconciliation project at a West Virginia paper mill required more accurate steam consumption; choosing the right flow-measurement device and transmitter among many options was imperative. Scott Hosier-Carotek, and Jonathan RoweInvensys/Foxboro A s part of an energy balance and reconciliation program, a West Virginia paper mill is in the process of implementing a plan to increase the number of steam and water flow rate measurements. This effort is part of an energy balance and reconciliation program designed to produce very significant cost savings in mill steam production. To obtain the required steam flow rate measurements, the mill’s engineering staff considered several types of flowmeters and differential pressure/ primary device combinations before making a final decision. Understand the application Applying a multi-variable transmitter for measuring flow, pressure, and temperature, simplifies the installation. Main steam flow from the mill’s industrial boiler goes into a 12-in. (300-mm) diameter header, operating at a nominal steam pressure of 1,200 psig (8.3 MPa). At the flow rate measurement point the steam is superheated and is at a nominal operating temperature of 900 °F (480 °C). Selection of a flowmeter for an application of this type requires considering accuracy, ability to withstand high-pressure/high-temperature steam, resistance to wear, dimensional stability with temperature change, flow turndown range, and cost. Linear in-line meters, such as vortex or mass flowmeters, are generally unsuitable for this application because of high pressure, high temperature, and large line size. The likely solution for such applications is usually a square root flowmeter, formed by pairing a differential-producing primary flow element and a differential pressure transmitter. That’s the basic approach mill engineers chose to pursue. Select the primary element Deciding the type of primary flow element that would provide the most accurate measurement and be the most reliable in this application was the next decision facing mill staff. Mill engineers turned to Richard W. Miller’s “Flow Measurement Engineering Handbook” (1996, McGraw Hill, New York, NY) and found the following quote, “The flow nozzle has an elliptical (ASME) or a radius (ISA) entrance and is generally selected for steam (vapor) flows at high pipeline velocities [100 ft/s (30.5 m/s)]. Because of its rigidity it is dimensionally more stable at higher temperatures and velocities than an orifice.” Mr. Miller went on to say, “When both are sized to create the same differential at the same flow rate, the pressure loss of a flow nozzle is approximately the same as for an orifice. Standards used for Measurement points are seldom convienent. Attention to detail during design and installation makes maintenance a lot easier. Calculating mass flow To calculate the mass flow rate of superheated steam using a differential producer primary flow device, such as a flow nozzle, the following basic flow-rate equation must be solved. Mass Flow Rate = N Cd E Y d2 (ph)1/2 , where: ■ N is the unit’s conversion factor; Cd is the discharge coefficient--a function of Beta Ratio, type of primary device, and Reynolds Number. (The Beta Ratio, ß, is bore diameter (d) divided by internal pipe diameter (D). The Reynolds Number is a function of velocity, density, and viscosity); ■ E is the velocity of approach factor, which accounts for change of velocity through the primary device and is a function of Beta Ratio, ß; ■ Y is the gas expansion factor, accounting for changes of fluid density through the primary device; ■ d is bore diameter; ■ p is fluid density at operating pressure and temperature; and ■ h is differential pressure across the primary device. ■ construction, installation, and accuracy are defined in ISO 5167 (1991) and ASME MFC-3M (1995).” High pressure, high temperature, and high flow rates exactly described the mill’s application, thus the engineers chose a flow nozzle as the primary element. Select the transmitter Selecting the transmitter most capable of providing an accurate measurement of superheated steam flow was the one remaining issue facing mill engineers. Steam is generally measured and accounted for on a mass basis using flow measurement units such as pounds per hour (lb/hr) or kilograms per hour (kg/hr). Because the mill also needed an accurate mass measurement that accounted for changes in steam pressure and temperature, it was decided three independent measurements--differential pressure (DP) across the flow nozzle, pressure (P), and temperature (T)-would be required. The traditional approach would be to purchase and install three transmitters-one for DP, one for P, and one for T. A three-transmitter solution to obtain mass flow incurs high device purchase costs and high installation and wiring costs. Instead, the mill project engineers decided to use multivariable transmitter technology. The multivariable transmitter resembles a traditional DP transmitter, but includes measurements of DP and P, and it can accept lead wires from an external temperature-measuring element. Hosting the DP, P, and T measurements, the transmitter can calculate mass flow rate and provide a 4-20 mA or digital output signal, representing mass flow rate. (See “Mass-flow calculation” sidebar.) Dynamically solving a mass flow equation also requires using pressure and temperature values to simultaneously calculate correction variables contained in the formula. For the superheated steam application at the mill, the dynamic correction variables are: ■ Discharge coefficient, Cd, which changes with viscosity; ■ Expansion Factor, Y, which changes with P, DP, and isentropic exponent; ■ Steam Density, p, which changes with P and T; and ■ Thermal expansion of the pipe and flow nozzle, which varies with T. Each of these dynamic correction variables are continually calculated in the multivariable transmitter and used in the flow rate equation to continually calculate mass flow using the physical properties of the steam in accordance with ASME requirements. Install it correctly To calculate superheated steam density and compensate for thermal expansion of the primary device and pipe, the process temperature, T, must be continuously measured. The multivariable transmitter accepts the wiring connections of an external resistance temperature detector (RTD) inserted into the pipe to measure steam temperature. The RTD is inserted into a thermowell designed to withstand pipeline pressure and temperature conditions. The thermowell and RTD must be installed in a location where the measured temperature is representative of the steam temperature in the pipeline at the point where pressure is being measured. This assures density, viscosity, and isentropic exponent calculations of the steam are accurate and in accordance with the ASME steam tables. Because mill steam temperature (approximately 900 °F or 480 °C) is higher than the maximum allowable temperature rating of the transmitter body (250 °F or 121 °C), the transmitter is mounted below the level of the flow nozzle. The pipes connecting the flow nozzle taps and the transmitter are filled with water. This isolates the transmitter from the high temperature steam and allows the transmitter to operate at ambient temperature. The calculation of steam density by the multivariable transmitter requires the transmitter have appropriate equations to define the relationship of steam density to pressure and temperature for a range of operating pressures and temperatures. Also, to calculate the mass flow rate, the transmitter must contain constants that are used to determine the coefficient of discharge for the selected primary device. Multivariable transmitters can be used for many applications in addition to steam, including almost any liquid, gas, or vapor. Therefore, the equations in the transmitter are common regardless of application and appropriate coefficients are downloaded to the transmitter as part of the transmitter configuration process. Configure it correctly Facilitation of the configuration setup is through PC-based software that allows users to input relevant application data, such as the fluid being measured, primary device type, boreand pipe-size, etc. To ease device configuration, the software includes a physical properties table for many common fluids, so the user only needs to select the name of the fluid, rather than having to input data about fluid density variations. Also, the configuration software provides selections for the type of primary device being used, thus eliminating the need to research and enter coefficients for each type of primary device. For example, the flow nozzle selections and the physical properties of saturated and superheated steam are included in the configuration software used by the mill to set up the multivariable transmitter. Following simple, yet critically important steps, mill engineers sifted through options to select and apply the correct measurements for the application. For accurately measuring superheated steam, this turned out to be a flow nozzle and a multivariable transmitter. The next problem may require something different. In process instrumentation, many options often are suitable, however, some options will always provide better overall results than others. The trick is to take the time to develop the one best solution. For more information, call Invensys Foxboro at 866-746-6477, or visit www. foxboro.com/m&i By locating the transmitter below the measurement point, the sensing lines can be filled with water. The water isolates the transmitter from the super-heated steam. 304771 Foxboro IMV30 multivariable transmitter When used with in-line primary flow devices, Foxboro’s IMV30 multivariable transmitter measures mass or standard volume flow rate of liquids, gases, or vapors. Output signals include 4-20 mA, HART, and Foxboro FoxCom digital communications. The IMV30 is offered with a choice of differential pressure ranges from 0-0.5 to 0-840 inH2O (0-0.12 to 0-210 kPa) and pressure ranges from 0-1 to 0-1,500 psia (00.007 to 0-10 MPa). The transmitter connects directly to an external 2, 3, or 4wire RTD without need for special cables or connectors. Supplied as standard with 316ss wetted parts (316Lss for the sensor), the IMV30 is optionally available in Hastelloy C process wetted parts for applications in corrosive fluids. Transmitter accuracy is +/0.075% of span (4-20 mA) and +/0.05% of span (digital) for differential and absolute pressure measurements, for spans from 100% to 10% of upper range limit. Other performance specifications, including ambient temperature effect, static pressure effect, and long-term stability have been optimized to reduce Total Probable Error (TPE). PC-based software, called PCMV, is provided to configure the transmitter for application-specific flow rate Reprinted from Instrumentation & Control, February 2003 by RSiCopyright. Copyright © Reed Business Information, a division of Reed Elsevier, Inc. All rights reserved. For reorders call RSiCopyright 651.582.3800. For subscription information call 630.320.7118. The Total Solution for Your Measurement Needs PRESSURE AND DP TRANSMITTERS • Economical analog output version has intelligent transmitter features • Digital output versions also available • Exceptional performance ELECTROCHEMICAL/ANALYTICAL • Easy analyzer operation reduces maintenance time • Patent-pending pH glass increases sensor life • Auto-buffer pH calibration provides higher accuracy FLOWMETERS • Handle a wide variety of liquids • Measurement not affected by process variables • High percent of rate accuracy Call us at 1-866-746-6477 or visit us at www.foxboro.com/m&i AR560

© Copyright 2026