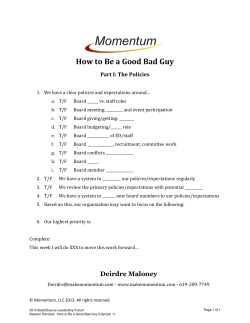

AUTHOR QUERY FORM