What is a swimming pool? Chapter 1

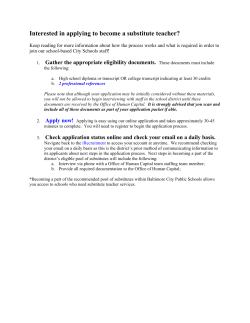

SWP 08 Chapter 1:swp 26/02/2009 09:33 Page 1 Chapter 1 What is a swimming pool? In pre-historic times people swam, if they did, in natural waters. The Indus Valley (in modern Pakistan) has the remains of a 60-metre mud brick pool lined with tar, built about 3,000BC. Swimming pools were built by the ancient Greeks and Romans and used mainly for athletic and military training. Roman emperors had private pools in which they also kept fish. A typical swimming pool needs four major components: • a tank (basin, shell) • a circulation system – pumps, inlets and outlets, pipework • filtration • a dosing system for treatment chemicals. The first indoor pools in England were built early in the 19th century. Largely untreated, early swimming pools got dirtier as the days went by and had to be emptied and refilled. When charging came in, the price of a swim might fall as the water got dirtier. Another way round the problem of pollution was to build pools that water flowed through on a continuous basis, usually from a nearby stream. The basic idea is to pump water in a continual cycle, from the pool via filtration and chemical treatment and back to the pool again. By this circulation, the water in the pool is kept relatively free of dirt, debris and microorganisms (bacteria and viruses). Other processes are included – heaters, for example. And it must be possible to make up water lost by evaporation, backwashing the filters and bathers carrying it out of the pool on costumes etc. These days all but the humblest pool is quite a bit more complicated than that. How pool tanks are built How swimming pools work Swimming pools come in all shapes and sizes, but nearly all of them, from the domestic to the Olympic, from the rectangular to the variously shaped leisure, work in the same basic way. Anything with more than about 5 cubic metres of water normally uses a combination of filtration and chemical treatment to clean continually by recirculation a large volume of water. The main difference between pools is how the tank is constructed. There are several different pool styles, each with its own advantages and disadvantages. This is not the place to give construction details, but a summary may be useful background. While these pool construction methods are quite different, they all rely on similar basic circulation and treatment systems. Concrete pools Concrete pools are usually finished in tiles or mosaic. As these are not flexible, the pool tank FIG 30. TYPICAL POOL WATER CIRCULATION SYSTEM pH CORRECTION BASE OUTLETS CHLORINE & pH MEASUREMENT CIRCULATION PUMP PRESSURE SAND FILTER STRAINER SWIMMING POOL BALANCE TANK A typical pool water circulation and treatment system DISINFECTANT INJECTION COAGULANT DOSING CALORIFIER/HEAT EXCHANGER Chapter One 9 SWP 08 Chapter 1:swp 26/02/2009 09:33 Page 2 A domestic pool under construction and complete must be reinforced concrete, designed as a monolithic structure by a structural engineer and fit to be built into the geological conditions of the site chosen The standard for reinforced concrete structures is British Standard 8110-1: 1997 Structural use of concrete. British Standard 8007: 1987 Design of concrete structures for retaining aqueous liquids is an adjunct to BS8110. Generally speaking the vast majority of commercially built swimming pools and a small percentage of domestic pool tanks are built to BS 8007. This requires that the pool tank is inherently watertight (strictly, up to 10mm loss per week). It does not rely on waterproof renders or applied finishes to stop leaking. It must be water tested after construction and before the internal finishes are applied to confirm this. Pool tanks built to BS8110 are steel reinforced structures but are not in themselves watertight; this is achieved by the application of a waterproof render and screed. The method of construction can vary depending on the structural engineer, the capabilities of the pool builder and cost considerations. Generally speaking pools built to BS8007 are more expensive due to the higher degree of civil engineering. The general methods of construction are permanent shuttering, temporary shuttering and sprayed concrete. There are a whole range of surface finishes which can be applied either direct onto the concrete, or onto renders applied to the concrete when a smooth true surface or fine dimensional tolerance is important. The most common finish used is a ceramic tile or mosaic which will give a long service life and should be designed and applied 10 in accordance with British Standard 5385 Wall and floor tiling, with particular reference to part 4 which covers the application of ceramics in wet or submerged conditions. Pre-formed sectional (PFS) pools Over the last 25 years or so the design and installation of PFS pools have developed substantially. They can be made from a range of materials including welded stainless steel plate, stainless steel, galvanised panels and glass reinforced plastic panels that are bolted together. Water retention is achieved with a heavy-duty uPVC membrane. PFS pools can be prefabricated offsite and assembled quickly onsite. They have been used particularly for 25 and 50m pools, notably as temporary (demountable) pools for international swimming competitions. Vinyl-lined in-ground pools The vinyl-lined pool has no structural strength to speak of, as it is watertight only because of its uPVC flexible liner. The structure’s wall assembly can be blockwork, preformed plastic, composite or galvanised tin panels or even timber. The floor is porous to allow the ground water pressure to move the liner and push into the pool, thus preventing the pool assembly being distorted. The factory-made vinyl lining may be secured just at the top, under the paving slabs, or the onsite vinyl lining secured to the structural wall. These pools are almost only used in the domestic market. Swimming Pool Water SWP 08 Chapter 1:swp 26/02/2009 09:33 Page 3 Pre-formed (one-piece) pools water pressure. This last is a SPATA requirement. These are made from glassfibre-reinforced plastic or ceramic, moulded in one piece into a tank shape, with the necessary plumbing fitted according to the manufacturer’s instructions. To install the pool, an appropriately sized hole is prepared and the preformed pool lowered into the hole and a surround constructed. Such pools can be installed within a week or two, and are popular in the domestic market. Care must be taken emptying or filling pools (see page 38). A tiled pool must be filled or emptied at a constant rate no greater than 750mm in 24 hours and the water heated at a constant rate no greater than 0.25ºC per hour to avoid thermal shock. Above-ground pools These can be the cheapest construction option, as well as the easiest to build. Most above ground pools are made from prefabricated kits, designed for an amateur to put together (though some people use professional installers). The main disadvantage of this sort of pool is that it's less durable than other designs, and generally less attractive. Their impermanence can be a good thing: it's relatively easy to disassemble the pool and move it to a new location. Large ones have been used in public swimming competitions. Full and empty A concrete in-ground swimming pool may seem like a solid, immovable structure, but it is actually rather like a boat: it can float where the surrounding ground water table is high. Unless the tank has been designed to withstand uplift when the pool is empty, the ground water pressure can actually push the pool up out of the ground. Partly in order to resist this pressure, in-ground pools are generally kept full all year round. Many in-ground pools have a special hydrostatic relief valve near the main drain to guard against damage from ground water pressure. Basically, if the ground water pressure is great enough, it will push up on a small float, which opens the valve. When the valve opens, ground water flows into the main drain and equalises the pressure. The seal on this type of valve needs regular careful maintenance to keep it free of grit and silt and stop pool water leaking into the surrounding ground. This approach to equalising the pressures will restrict the opportunity for maintenance to times when the water table is at its lowest, which unfortunately is likely to be mid summer, when the pool is most in demand. Most publicly owned pools, and an increasing number of private ones, are constructed to BS8007 (see page 10) and designed by a structural engineer to resist the uplift from ground Chapter one Leaks The commonest leakage problem in small pools is when pipework and fittings (skimmers, underwater lights, main drain etc) run through the walls and floor of the pool tank. So great care needs to be taken to ensure a good watertight joint at these interfaces. The circulation system This subject is dealt with in detail in Chapter 6, but for the purpose of understanding simply how pools work, here is a summary. Outlets and inlets During normal operation, pool water is removed at the bottom of the pool through two or more main drain outlets and from the surface perimeter of the pool into deck-level transfer channels, skimmers or overflow channels. The bottom outlets are usually on the lowest point in the pool, so that the entire pool floor surface slopes toward them. Most of the dirt and debris, heavier than water, will sink and leave the pool through these outlets. Some debris will usually have to be vacuumed up. The surface water draw off system works the same way as the main outlets, but they should take water only from the very top of the pool. As a result, any pollution that more or less floats – skin cells, hair etc – leaves the pool from the surface. Today most public pools work on the deck-level principle: up to 80% of water removal is actively drawn from the surface of the pool, overflowing via transfer channels round the pool. Inlets and outlets also need to be safely designed, with a safe water flow rate. The designer specifies the number and arrangement needed to achieve the recommended flow rates. To keep people from getting their hair or limbs caught in the pipework, the outlets are covered with grilles or special covers. Water is drawn out of the pool by circulation pumps through the pool outlets, and is returned to the pool via the filtration and treatment systems, through the pool inlets. 11 SWP 08 Chapter 1:swp 26/02/2009 09:33 Page 4 Pumps The heart of the pool system is the water circulation pump. In a typical pool one or more electric pumps will draw water from the pool, pull it through a strainer and push it through the filtration system and back into the pool. At appropriate points chemicals are dosed to treat the pool water. Filtration This is the subject of Chapter 7. The filters shown here are sand filters. Sand filters consist of a large circular tank, usually made of glass fibre, reinforced plastic or steel, containing a bed of special, even-graded sand, which has sharp edges. During filtration, dirty water from the pool is pumped down through the filter bed and the tiny sand particles capture the many insoluble pollutants that can be filtered. At the bottom of the tank, the filtered water flows through the collection system and out of the outlet pipe. Over time, the debris collected in the sand slows down the water flow. If gauges show an increase in pressure on the inlet pipe compared to the outlet pipe, the operator knows there's a lot of collected debris in the sand. This means it's time to backwash (cleanse) the filter. To backwash, the operator (usually having to switch off the circulation pump first) adjusts a number of valves to reverse the water flow, so water from the pump pushes up through the sand, dislodging the debris. Automatic backwash systems are also available. At the top of the filter tank, the dirty water flows out through the inlet pipe and into the sewer. Domestic and small commercial pools normally have a single-handle ‘multiport’ valve to operate the various filter functions. Larger pools have a four or five-valve frontal system. Diatomaceous earth filters use filter membranes (or septa) coated with this fine powder. When it gets dirty, it has to be removed, everything cleaned and the membranes recoated with fresh diatomaceous earth. In a cartridge filter, the polyester cloth (usually) or (in some domestic pools and spas) corrugated paper filter cartridges are removed, soaked in a bucket of cleaning chemical, hosed off and dried. So at least two sets of filter elements are needed. After up to a year, the filter element is replaced. For a filter to do its job, all the water in the pool (or more accurately, the equivalent volume) must 12 pass through the filter in a certain amount of time – typically between 30 minutes and six hours – depending on the type of pool (spas, 6-15 minutes). That time is called the turnover period, and has to be related to the bathing load (number of bathers) the pool can take. The pool and filter system is usually connected (via a break tank) to the mains so fresh water can be added to the pool. This is necessary to replace water lost to evaporation, backwashing and the water that is carried out on people's bodies and swim suits. Fresh water is added also to dilute the pool water in order to remove some of the chemical contaminants that accumulate. In the UK replacing up to 30 litres of pool water with fresh water per bather is recommended (see page 24 for more on this). Chemical disinfection The pool's filter system does the hard work in keeping the water clean, but it takes chemistry to make sure pool water is safe and suitable to swim in. Again, this subject is dealt with in detail elsewhere (Chapters 8, 9, 10 and 11) but in summary it's important to control the pool’s chemistry for four reasons. • Some disease-causing microorganisms – eg bacteria and viruses – thrive in untreated water. Without disinfection, there can be cross-infection among bathers. • pH values can affect the activity and efficiency of disinfectants. • Low free chlorine and/or high pH values can result in cloudy water; this is unpleasant and can be dangerous if a swimmer gets into trouble and can’t be seen. • Failure to maintain appropriate chemical concentrations in the pool water can affect users’ health and damage parts of the pool and its associated equipment. Disinfectants The most popular pool disinfectant is the element chlorine, usually in the form of a chemical compound such as calcium hypochlorite (a solid) or sodium hypochlorite (a liquid). When the disinfectant is dosed into the water, it reacts to form various chemicals, most notably hypochlorous acid, the prime disinfectant. It must be monitored, in milligrams per litre (mg/l) or parts per million (ppm) – exact equivalent measures of what is called free chlorine. Depending on the pool and its clientele, the free chlorine residual might be anything from 0.5–2.5mg/l, in order to keep the microorganisms under control. Swimming Pool Water SWP 08 Chapter 1:swp 26/02/2009 09:33 Page 5 Because hypochlorous acid is an oxidant as well as a disinfectant, it tends to combine with pollution from bathers to form byproducts that don’t disinfect and can irritate eyes, noses and chests. In particular, ammonia from sweat and urine combines with chlorine to form chloramines. This is the irritant smell associated with swimming pools – not chlorine (which is virtually odourless). Pool operators have to ensure through an effective system of engineering and control that the level of chloramines is as low as possible. They must in any case be less than half those of the free chlorine value measured in the pool. It is also important to minimise the ammonia and other pollution going into the pool by encouraging bathers to use toilets and showers before swimming. Chlorine is normally introduced into the pool water in the plant room, usually just before or after the filter (but see page 82). The whole process can be automated so that the pool water is monitored and dosed appropriately – continuously. One problem with hypochlorous acid is that it can degrade rapidly when exposed to ultraviolet light from the sun. Some organic disinfectants include a stabilising agent, usually cyanuric acid, that reacts with the chlorine to form a more stable compound that does not degrade as easily when exposed to sunlight. Or cyanuric acid can be added separately alongside an inorganic disinfectant (hypochlorite) to achieve the same effect. Water balance Pool water chemical values must be right for disinfection, safe for swimming and good for pool materials. That means attention to pH, alkalinity, hardness and dissolved solids. See Chapters 10 and 11. They need to be measured regularly (and of course the pool water has to be tested for microbes – Chapters 12, 13 and 14). Overlapping circles of chemical treatment and filtration – result, disinfection FIG 31. DISINFECTION CHEMICAL TREATMENT DISINFECTION FILTRATION TREATMENT than 200), to act as a buffer that helps keep the pH value relatively stable. Calcium hardness is controlled so that the pool water is neither corrosive to pool materials nor scale producing. The ideal range is 80-200 parts per million. Total dissolved solids (TDS) should be no more than 1,000 parts per million above the TDS of the mains water. Dilution with mains water is likely to be the only way to reduce it. Temperature also has an effect – see page 36. Working out the cost The budget for building the pool is only one consideration. The operating cost will be ongoing in terms of labour, chemicals, water, energy, maintenance and periodic replacement of equipment. The whole of life costs should be considered before reaching a decision on the specification. The pH value is a measure of how acid or alkaline (strictly, basic) the water is. Neutral water is pH value 7; lower than that the water is increasingly acid, above it basic. Depending somewhat on the disinfectant used, the pool’s pH value should be maintained (by adding alkalis or acids as necessary) at 7.2-7.4, ideally. Below that and the water may be irritant to bathers and corrosive to pool materials; higher and disinfection won’t be so effective (so more chlorine is needed). Total alkalinity is a measure mainly of alkaline bicarbonates and carbonates in the water. It should be more than 80 parts per million (but less Chapter One 13 SWP 08 Chapter 1:swp 26/02/2009 09:33 Page 6 A public pool during construction and in use 14 Swimming Pool Water

© Copyright 2026