? What is a LOPA

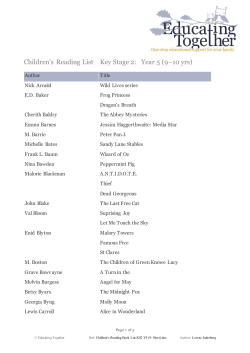

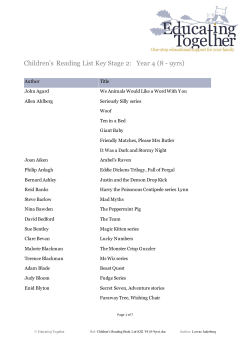

What is a LOPA? LOPA stands for Layer of Protection Analysis LOPA is a process to evaluate risk with explicit risk tolerance for a specific consequence It’s about creating value without taking unnecessary risk The level of risk acceptance is expressed in terms of tolerable frequency Tolerable frequency is a decision criteria The higher the consequence… the lower the tolerable frequency Single fatality risk tolerance* 0.01% per year Compared to… Multiple fatality risk tolerance* 0.001% per year *Generalized risk tolerance in an industrial environment Let’s try to make these numbers resonate with some relativity Driving fatality 0.01% per year (i.e. same as the acceptable risk for industrial work environment) [NIOSH 1997] Alaska crab fishing fatality 0.356% per year (i.e. 35x the acceptable risk for industrial work environment) [NIOSH 1997] Do you know the tolerable frequency of for your company? If so, who decide how much risk your company can take on? Are the decisions consistent across the company? Lets break down the LOPA into seven steps: Step 1: Identify a single consequence to analyze In our example, the reboiler condensate pot can overpressure leading to vessel rupture and resulting in a single fatality D-101 Re-boiler Condensate Pot PSV 111 Size ½ SET @ 700kPag To atmosphere at safe location Steam D-101 Drawing Ref. 3/4” LT 253 2” 3” HLL=2550 mm NLL=1650 mm PG 253 LLL=250 mm LC 2” 3” 253 3/4” LY 253 6” LV 253 6” Condensate 6” 6” Drawing Ref. 6” Step 2: Define the tolerable frequency for the consequence Multiple • 0.001%/year Fatality Single Fatality Hospitalized Injury •0.01%/year • 0.1%/ year Step 3: Assess the probability of the initiating events The level control valve can fail in the closed position leading to overpressure D-101 Re-boiler Condensate Pot PSV 111 Size ½ SET @ 700kPag To atmosphere at safe location Steam D-101 Drawing Ref. 3/4” LT 253 2” 3” HLL=2550 mm NLL=1650 mm PG 253 LLL=250 mm LC 2” 3” 253 3/4” LY 253 6” LV 253 6” Condensate 6” 6” Drawing Ref. 6” Let’s say this control loop has a 0.1 probability (10% chance) of failure per year Step 4: Identify independent protection layers and assign a risk reduction factor Important! Each protection layer must be independent from the initiating event and independent from other safeguards D-101 Re-boiler Condensate Pot PSV 111 Size ½ SET @ 700kPag To atmosphere at safe location Steam D-101 Drawing Ref. 3/4” LT 253 2” 3” HLL=2550 mm NLL=1650 mm PG 253 LLL=250 mm LC 2” 3” 253 3/4” LY 253 6” LV 253 6” Condensate 6” 6” Drawing Ref. 6” Let’s say the pressure safety valve will reduce the likelihood of rupture by 100 or you can say… Risk Reduction of 100 you can also say… the Probability of Failure on Demand of 0.01 Step 5: Calculate the new expected frequency of the consequence Expected frequency = initiating events frequency x probability of failure of the safeguard New expected frequency = 0.001 (0.1 valve failure per year x 0.01 probability of safety valve failure) D-101 Re-boiler Condensate Pot PSV 111 Size ½ SET @ 700kPag To atmosphere at safe location Steam D-101 Drawing Ref. 3/4” LT 253 2” 3” HLL=2550 mm NLL=1650 mm PG 253 LLL=250 mm LC 2” 3” 253 3/4” LY 253 6” LV 253 6” Condensate 6” 6” Drawing Ref. 6” Given a person will be around the vessel when ruptured… Our expected frequency of a fatality in this scenario is 0.001 per year Or 0.1% chance of a fatality per year D-101 Re-boiler Condensate Pot PSV 111 Size ½ SET @ 700kPag To atmosphere at safe location Steam D-101 Drawing Ref. 3/4” LT 253 2” 3” HLL=2550 mm NLL=1650 mm PG 253 LLL=250 mm LC 2” 3” 253 3/4” LY 253 1/1000 chance a fatality per year 6” LV 253 6” Condensate 6” 6” Drawing Ref. 6” Step 6: Decide if risk is acceptable based on the tolerable frequency Expected frequency of a single fatality = 0.001/year Tolerable frequency of a single fatality = 0.0001/year That’s 10 times more likely than the maximum frequency your company can accept for a single fatality Step 7: Determine additional safeguards to reduce the risk Let’s add a high pressure shutdown to the inlet as a safeguard D-101 Re-boiler Condensate Pot PSV 111 XV 253 Size ½ SET @ 700kPag To atmosphere at safe location Steam D-101 Drawing Ref. LT 253 2” 3” HLL=2550 mm HH NLL=1650 mm PT 253 LLL=250 mm LC 2” 3” 253 LY 253 6” LV 253 6” Condensate 6” 6” Drawing Ref. 6” This safeguard consist of a pressure sensor, logic solver (independent from the level control) and a valve as a final element This safeguard is a safety instrumented function (SIF) XV 253 PT 253 Since we need to reduce the risk by a factor of 10… The probability of failure on demand of the safety instrumented function must be less than 0.1 Or you can say the safety instrumented function must meet the requirements of safety integrity level 1 This safety instrumented function is at SIL 1 XV 253 PT 253 Expected frequency with the new safeguard = 0.1 probability of valve failure per year x 0.01 probability of safety valve failure x 0.1 probability of the safety instrumented function failure =0.0001/year New expected frequency of a single fatality = 0.0001/year Tolerable frequency of a single fatality = 0.0001/year Now the risk is acceptable Adding a safety instrumented function is one option to meet the tolerable frequency. Is it a good decision? Is there a better option? Any Questions? Risk. Inspired. For more lessons go to www.icarus-orm.com

© Copyright 2026