Blast Resistance of UHPFC and FRP Retrofitted RC Slabs

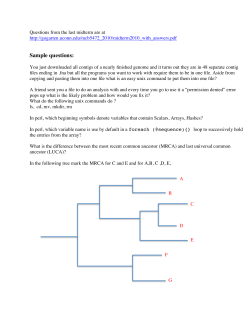

1. Introduction Performance of Ultra-High Strength Concrete and FRP Retrofitted RC Slabs under Blast Loads Why? Chengqing Wu, Oehler DJ, Rebentrost M, Leach J, Whittaker AS • Terrorism • Ultra-high Performance Concrete • Retrofitting technologies School of Civil, Environmental and Mining Engineering, The University of Adelaide 1. Introduction 1. Introduction Blast Testing of FRP retrofitted RC members Mechanical properties of conventional concrete and UHPFC Test Specimen 1000 mm A Section A-A A 1.4 1300 mm 20 150 100 200 100 200 100 150 Blast Test 1: ELASTIC RANGE PLASTIC RANGE Blast Test 2: 2 Test Program Compression Stress ((MPa MPa)) 2 Test Program Blast Testing Specimens 160 140 Normal Reinforced Concrete Specimens 120 100 1000 80 A 60 10 Section A-A 100 2000 1000 20 0 0 Retrofitting A 40 0.005 0.01 0.015 Strain Major Bending Plane Minor Bending Plane Ultra high performance concrete 1 2 Test Program 2 Test Program Retrofitted Reinforced Concrete Specimens 100 40 CFRP 1.4 mm Pultruded: 100 40 Adhesive 155 240 Testing Set-up 100 100 240 210 155 Ultra-high Performance Concrete Specimens Two slabs of UHPFC with and without reinforcement were designed. Blast Setup 2 Test Program Data acquisition Support PT1 Explosive Charge Slab LVDT Pressure Transducer (PT) LVDT PT2 50 mm Support 20 mm Concrete Slab 2 Test Program Experimental air blast program Blast Slab Name Description Dimension mm*mm*mm Reo. Rate Standoff distance (m) Scaled distance (m/kg1/3) Explosive Used (g) NRC-1 1A NSC RC 2000*1000*100 1.2 % 3 3.0 1007 NRC-2 1A NSC RC 2000*1000*100 1.2 % 3 1.5 8139 NRC-3 1B NSC RC 2000*1000*100 1.2 % 1.4 0.93 3440 NRC-4 1A NSC RC 2000*1000*100 1.2 % 1.5 0.75 8213 RET-1 3A RC+CFRP 2.8mm strip, one side (EB) 2000*1000*100 1.2 % 1.5 1.5 1044 RET-2 3B RC+CFRP 2.8mm strip, one side (EB) 2000*1000*100 1.2 % 0.92 0.54 5083 UUHPFC D1B UUHPFC 2000*1000*100 - 0.75 1.13 3433 RUHPFC D3A RUHPFC 2000*1000*100 1.4 % 1 0.37 20101 2 Retrofitted Experimental Results Performance of Testing Specimens Normal reinforced concrete slabs FRP Debonding NRC-3 crack development (a charge weight of 3.4kg at stand-off distance 1.4m, energy 2536 kN.mm) NRC-4 crack development Direct Shear Direct Shear Flexural (a charge weight of 5kg at stand-off distance 0.92m, energy 10375 kN.mm) (a charge weight of 8kg at stand-off distance 1.5m, energy 5464 kN.mm) 2 Test Program FRP Debonding Unreinforced ultra-high performance fibre concrete slab (a charge weight of 3.4kg at stand-off distance 0.75m, energy 3089 kN.mm) Normal reinforced concrete slabs NRC-3 crack development (a charge weight of 3.4kg at stand-off distance 1.4m, energy 2536 kN.mm) 3 Blast Resistance kN)) Resistance ((kN Reinforced ultra-high performance fibre concrete slab 700 Ultra high strength 600 500 400 Retrofitted 300 200 Normal reinforced concrete 100 0 10 20 30 40 50 60 Deflection (mm) (a charge weight of 20kg at stand-off distance 1m, energy 93077 kN.mm) 3 Resistance, reflected impulses and energy demands and capacities Comparison and Discussions Based on this diagram, almost all specimens (except NRC-1) tested in this study will collapse. 4. Conclusion A series of blast tests have been carried out to investigate blast resistance of the NRC, the retrofitted, the UUHPFC and the RUHPFC slabs. It was found that: Although EB FRP compressive face of retrofitting can increase ductility in blast tests, the effectiveness of the retrofitting was inconclusive as slab failure was not achieved throughout the experiments. 4. Conclusion Blast testing also validated the superior blast resistance of the RUHPFC slab due to the excellent mechanical properties of UHPFC. P-I diagrams specified by current codes are very conservative when they are used to assess damage levels of specimens tested in this study. The UUHPFC slab suffered even less flexural cracks at middle span by comparison with those for NRC slabs when it was subjected to similar blast loads, showing UHPFC is of high ductility and high energy absorption capacity, and is therefore a more effective material against blast loading. Questions? 4

© Copyright 2026