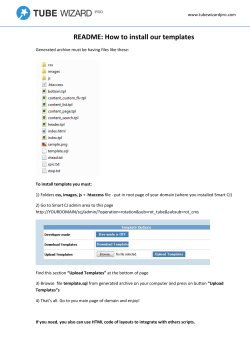

ATTACHMENT E-SAMPLE SPECIFICATION TEMPLATE