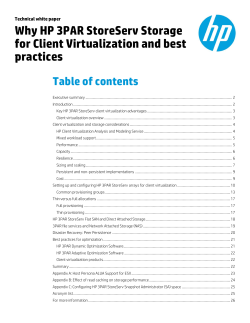

HP 3PAR StoreServ 7000 Storage Site Planning Manual Abstract