CHECKING AND MAINTENANCE:

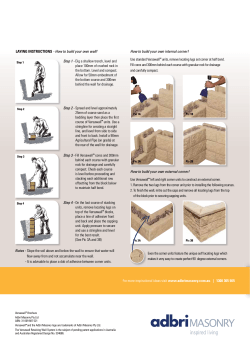

10-2005 CHECKING AND MAINTENANCE: To achieve an optimum performance and longer life of the equipment and in observance of the safety regulations, it is recommended that inspections and proper maintenance are made by qualified technicians to the whole installation ie, both the mechanical and electronic parts, as well as wiring: - Mechanical parts: maintenance every 6 months approx. - Eletronic apparatus and safety equipment: maintenance every month. IMPORTANT WARNING NOTES - Before installing the equipment carry out a Risk Analysis and fit any required device in compliance with EN 12445 and EN 12453 Safety Norms. - It is recommended to keep to the instructions here outlined. Check the specifications on the motor sticker with your mains supply. - Dispose properly of the packaging: cardboard, nylon, polystyrene, through specializing companies. - Should the operator be removed, do not cut the electric cable. This must be properly removed from the terminal board in the junction box. - Switch off the mains switch before removing the junction box cover where the electric cable is terminated. - All the system must be earthed by using the yellow/green wire, marked by its specific symbol. - It is recommended to read the regulations, suggestions and remarks quoted in the booklet “Safety Norms”. ® Made in Italy The growth of MECCANICA FADINI has always been based on the development of guaranteed products thanks to our “TOTAL QUALITY CONTROL” system which ensures constant quality standards, updated knowledge of the European Standards and compliance with their requirements, in view of an ever increasing process of improvement. The “CE” mark certifies that the operator conforms to the essential requirements of the European Directive art. 10 EEC 73/23, in relation to the manufacturer’s declaration for the supplied items, in compliance with the body of the regulations ISO 9000= UNI EN 29000. Automation in conformity to EN 12453, EN 12445 safety standards. EUROPEAN MARK CERTIFYING CONFORMITY TO THE ESSENTIAL REQUIREMENTS OF THE STANDARDS 98/37/EC • DECLARATION OF CONFORMITY • SAFETY NORMS • EN 12453, EN 12445 STANDARDS • CEI EN 60204-1 STANDARDS • WARRANTY CERTIFICATE ON THE CUSTOMER’S REQUEST ® Distributor’s box s.n.c. AUTOMATIC GATE MANUFACTURERS The manufacturers reserve the right to change the products without any previous notice and are not liable for possible damages to people and properties. Via Mantova, 177/A - 37053 Cerea (Verona) Italy - Tel. +39 0442 330422 r.a. - Fax +39 0442 331054 - e-mail: [email protected] - www.fadini.net GB INSTALLATION MANUAL ® APROLI 480 OIL-HYDRAULIC OPERATOR FOR GARAGE DOORS INSTRUCTIONS FOR THE INSTALLATION OF APROLI 480 TO A GARAGE DOOR WITH COUNTERWEIGHTS SECTION VIEW OF THE OIL-HYDRAULIC OPERATOR WITH LAMP AND COVER WEATHER STRIP UPPER SECTION SUPPORT DOOR HANDLE DOOR UPPER EDGE WALL FRAME DOOR JAMB LAMP REFLECTOR COUNTERWEIGHT WHEEL GARAGE DOOR LIGHT DIFFUSION COVER 230 V-25 W LAMP SCREW SEAT FOR FIXING THE COVER/UPPER SECTION GUIDE ARM LATERAL SUPPORT TELESCOPIC ARM ELECTRIC TERMINAL COVER COUNTERWEIGHT WEATHER STRIP ELECTRIC TERMINALS OIL CONTAINER “S” APROLI 480 COUNTERWEIGHT CASE WITH COVER AIR BLEED SCREW ELECTRIC MOTOR TOP END CAP WEATHER STRIP BOTTOM DOOR WHEEL O.33 HP ELECTRIC MOTOR FADINI OIL A 15 BY AGIP 100x5 mm REINFORCEMENT PLATE TO BE FIXED TO THE DOOR FRAME FIXING BRACKET “M” OIL RESERVOIR PIC. 2 HYDRAULIC LOBE PUMP FADINI OIL A 15 BY AGIP No change to the existing door is required for the installation of this operator. Automatic or semi-automatic operations. Hand operation can be made possible by releasing the system through the lever “B” both from inside or outside the building. (Pic.1) TWO-WAY LOCKING VALVE PRESSURE VALVE ASSEMBLY “B” “C”–“A” MANUAL RELEASE LEVER TWO-WAY LOCKING VALVE ASSEMBLY ESSENTIAL COMPONENTS FOR THE APPLICATION OF THE OPERATOR ON TO A GARAGE DOOR HAVING COUNTERWEIGHT (PIC.3) PISTON SLEEVE TERMINAL BOARD COVER FADINI OIL A 15 BY AGIP GEAR BOX HOUSING TOOTHED SHAFT SPACER BEARING/ GEAR TEETH COVER 1st PISTON WITH STEEL INSERT TELESCOPIC ARM “S” TELESCOPIC ARM SHAFT SUPPORT RACK AIR BLEED TRANSMISSION BAR WITH SHAFT FITTING SLEEVE (SQUARE HOLE) WELDED TO IT 2nd PISTON WITH STEEL INSERT MAX. PRESSURE SAFETY VALVE OPEN. RED “A” MAX. PRESSURE SAFETY VALVE CLOSE. GREEN “C” TRANSMISSION BAR LATERAL SUPPORT SCREW SEAT FOR FIXING THE COVER/BOTTOM END BOTTOM SECTION PIC. 1 2 FADINI OIL A 15 BY AGIP CYLINDER END CAP “M” FIXING BRACKET PIC. 3 3 APROLI 480 OIL-HYDRAULIC OPERATOR FOR GARAGE DOORS INSTRUCTIONS FOR THE INSTALLATION OF APROLI 480 TO A GARAGE DOOR WITH COUNTERWEIGHTS SECTION VIEW OF THE OIL-HYDRAULIC OPERATOR WITH LAMP AND COVER WEATHER STRIP UPPER SECTION SUPPORT DOOR HANDLE DOOR UPPER EDGE WALL FRAME DOOR JAMB LAMP REFLECTOR COUNTERWEIGHT WHEEL GARAGE DOOR LIGHT DIFFUSION COVER 230 V-25 W LAMP SCREW SEAT FOR FIXING THE COVER/UPPER SECTION GUIDE ARM LATERAL SUPPORT TELESCOPIC ARM ELECTRIC TERMINAL COVER COUNTERWEIGHT WEATHER STRIP ELECTRIC TERMINALS OIL CONTAINER “S” APROLI 480 COUNTERWEIGHT CASE WITH COVER AIR BLEED SCREW ELECTRIC MOTOR TOP END CAP WEATHER STRIP BOTTOM DOOR WHEEL O.33 HP ELECTRIC MOTOR FADINI OIL A 15 BY AGIP 100x5 mm REINFORCEMENT PLATE TO BE FIXED TO THE DOOR FRAME FIXING BRACKET “M” OIL RESERVOIR PIC. 2 HYDRAULIC LOBE PUMP FADINI OIL A 15 BY AGIP No change to the existing door is required for the installation of this operator. Automatic or semi-automatic operations. Hand operation can be made possible by releasing the system through the lever “B” both from inside or outside the building. (Pic.1) TWO-WAY LOCKING VALVE PRESSURE VALVE ASSEMBLY “B” “C”–“A” MANUAL RELEASE LEVER TWO-WAY LOCKING VALVE ASSEMBLY ESSENTIAL COMPONENTS FOR THE APPLICATION OF THE OPERATOR ON TO A GARAGE DOOR HAVING COUNTERWEIGHT (PIC.3) PISTON SLEEVE TERMINAL BOARD COVER FADINI OIL A 15 BY AGIP GEAR BOX HOUSING TOOTHED SHAFT SPACER BEARING/ GEAR TEETH COVER 1st PISTON WITH STEEL INSERT TELESCOPIC ARM “S” TELESCOPIC ARM SHAFT SUPPORT RACK AIR BLEED TRANSMISSION BAR WITH SHAFT FITTING SLEEVE (SQUARE HOLE) WELDED TO IT 2nd PISTON WITH STEEL INSERT MAX. PRESSURE SAFETY VALVE OPEN. RED “A” MAX. PRESSURE SAFETY VALVE CLOSE. GREEN “C” TRANSMISSION BAR LATERAL SUPPORT SCREW SEAT FOR FIXING THE COVER/BOTTOM END BOTTOM SECTION PIC. 1 2 FADINI OIL A 15 BY AGIP CYLINDER END CAP “M” FIXING BRACKET PIC. 3 3 It is recommended to follow the drawings in this manual to install APROLI 480 on to garage doors in order to automate them. The operator is designed for the installation in the centre of the existing door by means of a bracket “M” that is fixed to the door with screws. Pic.4 40 40 TELESCOPIC ARM OVERLAPPING THE DOOR ARM WHEN THERE IS NO SPACE BETWEEN ARM AND COUNTERWEIGHT 15 5° WALL FRAME DOOR JAMB DOOR FRAME FIXING ABOVE THE ARM PIVOT EXISTING GUIDE ARM 40 2˙500 DOOR FIXING FIXING ON TO THE GUIDE ARM GUIDE ARM OF THE EXISTING DOOR “M” COUNTERWEIGHT CASE AND ROLLER GUIDE TUBE PERPENDICULARLY FITTED BRACKET “M” TELESCOPIC ARM OVERLAPPING THE DOOR ARM WHEN THERE IS NO SPACE BETWEEN ARM AND COUNTERWEIGHT OPERATOR IN THE OPEN POSITION 10 FIXING ON TO THE GUIDE ARM 3˙0 00 REINFORCEMENT PLATE 100x5 mm PIC. 4 PIC. 6 Should the upper and lower fixing ends of the bracket “M” not coincide with the upper and lower edges of the door, it is recommended to rivet, screw or spot weld an iron reinforcement plate (100 mm - 5 mm thickness) vertically across the door so to connect the top and bottom edges of the door as shown in pic. 4 Once the bracket and the operator have been fixed to the door, proceed to temporarily fix the two telescopic arms to the torsion shaft, considering that the shaft must be allowed to rotate 5 degrees less than the end of the permitted stroke, as further explained in pic.7 TELESCOPIC ARM TO BE PARALLEL FIXED TO THE EXISTING DOOR ARM 15 FIXING PLATE TO WELD 90 END OF PISTON STROKE WHEN NO FURTHER TURNING IS ALLOWED 90 HYDRAULIC LOCKING/ UNLOCKING LEVER “B” 80 60 60 20 REINFORCEMENT ROTATE IN THE ARROW DIRECTION BY 5 mm TO GET 5° APROLI 480 CLOSED DOOR POSITION 100 x 5 OPEN 5 DOOR JAMB/ COUNTERWEIGHT CASE 5 mm PIC. 5 PIC. 7 Once the bracket “M” has been fixed, it is to be determined whether the telescopic arms are to overlap the existing door arms or be fixed parallel to them. See pic. 5 and 6. Then proceed to weld the fixing plates as indicated by the distances in pic.5 Rotate the shaft to the end of the permitted stroke by means of pliers. Then rotate the shaft back by 5 mm. This allows more power to the operator when it is required to close the door. Pic. 7. Please note the door must be in closed position when this operation is done. 4 5 It is recommended to follow the drawings in this manual to install APROLI 480 on to garage doors in order to automate them. The operator is designed for the installation in the centre of the existing door by means of a bracket “M” that is fixed to the door with screws. Pic.4 40 40 TELESCOPIC ARM OVERLAPPING THE DOOR ARM WHEN THERE IS NO SPACE BETWEEN ARM AND COUNTERWEIGHT 15 5° WALL FRAME DOOR JAMB DOOR FRAME FIXING ABOVE THE ARM PIVOT EXISTING GUIDE ARM 40 2˙500 DOOR FIXING FIXING ON TO THE GUIDE ARM GUIDE ARM OF THE EXISTING DOOR “M” COUNTERWEIGHT CASE AND ROLLER GUIDE TUBE PERPENDICULARLY FITTED BRACKET “M” TELESCOPIC ARM OVERLAPPING THE DOOR ARM WHEN THERE IS NO SPACE BETWEEN ARM AND COUNTERWEIGHT OPERATOR IN THE OPEN POSITION 10 FIXING ON TO THE GUIDE ARM 3˙0 00 REINFORCEMENT PLATE 100x5 mm PIC. 4 PIC. 6 Should the upper and lower fixing ends of the bracket “M” not coincide with the upper and lower edges of the door, it is recommended to rivet, screw or spot weld an iron reinforcement plate (100 mm - 5 mm thickness) vertically across the door so to connect the top and bottom edges of the door as shown in pic. 4 Once the bracket and the operator have been fixed to the door, proceed to temporarily fix the two telescopic arms to the torsion shaft, considering that the shaft must be allowed to rotate 5 degrees less than the end of the permitted stroke, as further explained in pic.7 TELESCOPIC ARM TO BE PARALLEL FIXED TO THE EXISTING DOOR ARM 15 FIXING PLATE TO WELD 90 END OF PISTON STROKE WHEN NO FURTHER TURNING IS ALLOWED 90 HYDRAULIC LOCKING/ UNLOCKING LEVER “B” 80 60 60 20 REINFORCEMENT ROTATE IN THE ARROW DIRECTION BY 5 mm TO GET 5° APROLI 480 CLOSED DOOR POSITION 100 x 5 OPEN 5 DOOR JAMB/ COUNTERWEIGHT CASE 5 mm PIC. 5 PIC. 7 Once the bracket “M” has been fixed, it is to be determined whether the telescopic arms are to overlap the existing door arms or be fixed parallel to them. See pic. 5 and 6. Then proceed to weld the fixing plates as indicated by the distances in pic.5 Rotate the shaft to the end of the permitted stroke by means of pliers. Then rotate the shaft back by 5 mm. This allows more power to the operator when it is required to close the door. Pic. 7. Please note the door must be in closed position when this operation is done. 4 5 Once satisfied that the installation is correct and smooth, remove the two torsion bars and the sliding bars in order to firmly fix them by welding all around. Pic.9 CLOSED DOOR FIXING PLATE “B” TELESCOPIC ARM LEVEL IN THIS POSITION THE DOOR MUST BE WELL BALANCED. SHOULD IT NOT, ADD SOME EXTRA COUNTERWEIGHT LEVEL FIX THE COVER ONLY AFTER COMPLETING THE INSTALLATION LATERAL SUPPORT LATERAL SUPPORT PROVIDED WITH THE EQUIPMENT TORSION BAR 45° PIC. 8 Fit the two telescopic arms to the torsion bars and make sure that they are perfectly perpendicular to them at the same distance from the door. Adjust the two supports to achieve the above and put some wooden spacers to bring the lateral supports to the required distance. A spirit level will ensure that the torsion bars are perfectly horizontal. See pic. 8. The lever «B» must be in the released position. PIC. 10 A good test to verify how well balanced the door is in both directions, ie. lifting and lowering, is to position it 45 degrees from ground level, as shown in picture 10. Add counterweight to improve running smoothness and balance if required. FIXING PLATE “S” AIR BLEED TELESCOPIC ARM WITH SLIDING BAR TELESCOPIC ARM WITH SLIDING BAR CUT TO MEASURE AND WELD CUT TO MEASURE AND WELD LEVEL LEVEL MAXIMUM PRESSURE VALVE “OPEN” RED IN COLOUR “A” MAXIMUM PRESSURE VALVE “CLOSE” GREEN COLOUR “C” “B” The two safety pressure valves are identified by colours: «A» Open is red; «C» close is green. They are located in the front of the motor/pump unit, easy to reach for setting operations in order to meet the power requirements.Pic.11 Once the valves are set, you can fit the cover and the other accessories. Pic.10 RELEASE LEVER TURN IT ANTI-CLOCKWISE LATERAL SUPPORT TORSION BAR WITH SLEEVE MORE POWER LESS POWER CIRCULAR WELDING The setting of the safety pressure valves is to be done so to achieve the exact amout of power required to safely operate the door. The more you turn the screw clockwise, the more you increase the power of the operator. PIC. 9 Fit the two telescopic arms and the torsion bars in the correct position and make sure that they are levelled and parallel, door in the closed position. Partially weld the torsion bars to the lifting arms and operate the door by hand. Verify that it can open fully in a quiet and smooth way. The lever «B» in the released position. Pic.8. 6 PIC. 11 7 Once satisfied that the installation is correct and smooth, remove the two torsion bars and the sliding bars in order to firmly fix them by welding all around. Pic.9 CLOSED DOOR FIXING PLATE “B” TELESCOPIC ARM LEVEL IN THIS POSITION THE DOOR MUST BE WELL BALANCED. SHOULD IT NOT, ADD SOME EXTRA COUNTERWEIGHT LEVEL FIX THE COVER ONLY AFTER COMPLETING THE INSTALLATION LATERAL SUPPORT LATERAL SUPPORT PROVIDED WITH THE EQUIPMENT TORSION BAR 45° PIC. 8 Fit the two telescopic arms to the torsion bars and make sure that they are perfectly perpendicular to them at the same distance from the door. Adjust the two supports to achieve the above and put some wooden spacers to bring the lateral supports to the required distance. A spirit level will ensure that the torsion bars are perfectly horizontal. See pic. 8. The lever «B» must be in the released position. PIC. 10 A good test to verify how well balanced the door is in both directions, ie. lifting and lowering, is to position it 45 degrees from ground level, as shown in picture 10. Add counterweight to improve running smoothness and balance if required. FIXING PLATE “S” AIR BLEED TELESCOPIC ARM WITH SLIDING BAR TELESCOPIC ARM WITH SLIDING BAR CUT TO MEASURE AND WELD CUT TO MEASURE AND WELD LEVEL LEVEL MAXIMUM PRESSURE VALVE “OPEN” RED IN COLOUR “A” MAXIMUM PRESSURE VALVE “CLOSE” GREEN COLOUR “C” “B” The two safety pressure valves are identified by colours: «A» Open is red; «C» close is green. They are located in the front of the motor/pump unit, easy to reach for setting operations in order to meet the power requirements.Pic.11 Once the valves are set, you can fit the cover and the other accessories. Pic.10 RELEASE LEVER TURN IT ANTI-CLOCKWISE LATERAL SUPPORT TORSION BAR WITH SLEEVE MORE POWER LESS POWER CIRCULAR WELDING The setting of the safety pressure valves is to be done so to achieve the exact amout of power required to safely operate the door. The more you turn the screw clockwise, the more you increase the power of the operator. PIC. 9 Fit the two telescopic arms and the torsion bars in the correct position and make sure that they are levelled and parallel, door in the closed position. Partially weld the torsion bars to the lifting arms and operate the door by hand. Verify that it can open fully in a quiet and smooth way. The lever «B» in the released position. Pic.8. 6 PIC. 11 7 The electric cable which supplies power to the motor/pump is connected by means of terminals, which are located above the oil container, next to the earth screw connection. The cable must be led along the door to the point where the telescopic arm is welded to the bar. It is recommended that the cable is allowed to dangle free by 130 cm so that the door can go fully up to the end of the permitted stroke. RELEASE LEVER “B” POSITION OF THE EARTH SCREW CONNECTION RUBBER STOP OPEN RECOMMENDED STARTING POSITION BEFORE CLOSE CYCLE RUBBER STOP ELPRO 6 exp 25 RUBBER STOP ON THE OUTSIDE OF THE DOOR CLOSE PIC. 12 OPEN The highest power is required to start the close cycle. Therefore it is recommended to fit rubber stops to the door. This will cushion the door at the end of the up stroke and will keep the door inclined by 5 degrees for a better start. See Pic.12. APROLI 480 WITH COVER CLAMP RELEASE LEVER “B” LOCKABLE HATCH DOOR ELECTRIC CABLE TO DANGLE FREE LENGTH 1.30 METRES PIC. 14 RELEASE CORD COURTESY LIGHT DOOR SECTION To release Aproli 480 for hand operations it is available a device as described above, on request. Turn the key sharply; this will pull the cord and the lever open. As an option you can fit the door with a service hatch. Pic.13 EXTRA CAPACITOR IN CASE OF POWER SHORTAGE OR TO IMPROVE THE POWER OF THE OPERATOR WHEN HEAVY DOORS ARE INVOLVED HATCH RELEASE LEVER DOOR FROM OUTSIDE TO REVERSE THE DIRECTION OF THE SHAFT ROTATION SWOP WIRES ROUND No. 10 AND No. 12 DO NOT CHANGE No.11 10 11 12 13 14 ELPRO 6 exp PIC. 13 PIC. 15 There are two solutions to get access to the operator release lever for hand operations of the door. Either a lock is fitted at a suitable distance from the release lever, to which it is connected by a steel flexible cord as in Pic.13; or a 12 cm x 12 cm lockable hatch is provided and fitted to allow a hand to pass from outside to inside and release the lever «B». It is essential to make sure that the shaft rotates in the required direction during the first running test. Should it rotate in the opposite direction, change wire No. 10 with No. 12. Pic. 15 8 9 The electric cable which supplies power to the motor/pump is connected by means of terminals, which are located above the oil container, next to the earth screw connection. The cable must be led along the door to the point where the telescopic arm is welded to the bar. It is recommended that the cable is allowed to dangle free by 130 cm so that the door can go fully up to the end of the permitted stroke. RELEASE LEVER “B” POSITION OF THE EARTH SCREW CONNECTION RUBBER STOP OPEN RECOMMENDED STARTING POSITION BEFORE CLOSE CYCLE RUBBER STOP ELPRO 6 exp 25 RUBBER STOP ON THE OUTSIDE OF THE DOOR CLOSE PIC. 12 OPEN The highest power is required to start the close cycle. Therefore it is recommended to fit rubber stops to the door. This will cushion the door at the end of the up stroke and will keep the door inclined by 5 degrees for a better start. See Pic.12. APROLI 480 WITH COVER CLAMP RELEASE LEVER “B” LOCKABLE HATCH DOOR ELECTRIC CABLE TO DANGLE FREE LENGTH 1.30 METRES PIC. 14 RELEASE CORD COURTESY LIGHT DOOR SECTION To release Aproli 480 for hand operations it is available a device as described above, on request. Turn the key sharply; this will pull the cord and the lever open. As an option you can fit the door with a service hatch. Pic.13 EXTRA CAPACITOR IN CASE OF POWER SHORTAGE OR TO IMPROVE THE POWER OF THE OPERATOR WHEN HEAVY DOORS ARE INVOLVED HATCH RELEASE LEVER DOOR FROM OUTSIDE TO REVERSE THE DIRECTION OF THE SHAFT ROTATION SWOP WIRES ROUND No. 10 AND No. 12 DO NOT CHANGE No.11 10 11 12 13 14 ELPRO 6 exp PIC. 13 PIC. 15 There are two solutions to get access to the operator release lever for hand operations of the door. Either a lock is fitted at a suitable distance from the release lever, to which it is connected by a steel flexible cord as in Pic.13; or a 12 cm x 12 cm lockable hatch is provided and fitted to allow a hand to pass from outside to inside and release the lever «B». It is essential to make sure that the shaft rotates in the required direction during the first running test. Should it rotate in the opposite direction, change wire No. 10 with No. 12. Pic. 15 8 9 ELECTRICAL WIRING DIAGRAM OF THE OIL-HYDRAULIC GARAGE DOOR OPERATOR APROLI 480 TO THE ELECTRONIC CONTROL PANEL GARAGE DOOR OPERATOR COMPLETE WITH ALL THE RECOMMENDED ACCESSORIES FOR A GOOD PERFORMANCE 230 VOLTS MAINS SUPPLY 1 BIRIO A8 AERIAL 2 TRANSFORMER 230 0 I.T.F. 9 3 4 6 5 7 8 9 1 R2 R1 ANT. N.A. C N.C . MOTOR RUN OPEN & CLOSE TIME R2 GND FUSE 630 mA 1° CHANNEL 2 R1 24 V OUTPUT 1 3 0 24 meth 8VA RADIO CONTROL PLUG-IN CARD SUPPORT ASTR INNESO 43 TO 0 PLUG-IN ASTRO 43 LED ON VOLTAGE SUPPLIED 4 10 CAPACITOR DIP-SWITCH ON ASTRO 43/2 RADIO RECEIVER PLUG-IN PC BOARD 1 DWELL TIME FUSES 5A 12,5 µF 2 1 2 3 4 5 6 7 8 9 11 5 12 10 11 12 13 14 15 16 17 18 COMUNE M1 230 V SINGLE-PHASE SUPPLY VOLTAGE 230 V - 25 W MAX. FLASHING LAMP 230 V - 25 W MAX. COURTESY LIGHT EARTH SINGLE-PHASE MAX. 400W ELECTRIC MOTOR MAX. PERMITTED LOAD: 1 PAIR PHOTOCELLS 1 RADIO RECEIVER 3 24 V OUTPUT A.C. LIMIT SWITCH. OPEN. N.C. LIMIT SWITCH. CLOSE. N.C. BUTTON ON THE COVER LID LIMIT SWITCH. COMMON N.O. CONTACT. OPEN SWITCH STOP CLOSE AND RADIO N.C. CONTACT. PHOTOCELLS AND SAFETY EDGE - COURTESY LIGHT FOR TWO MINUTES. ON - FLASHING LAMP. OFF - AUTOMATIC RE-CLOSING. ON - SEMI-AUTOMATIC.OFF Should more pairs of photocells be required than the recommended quantity, fit an auxiliary transformer outside the control box. NOTE WELL: THIS PANEL IS TESTED TO OPERATE GATES ONLY THROUGH FADINI ACCESSORIES. NO GUARANTEE FOR ACCESSORIES OF OTHER MAKE OR SPECIAL APPLICATIONS. OFF 6 en op 13 7 8 4 ALL OPERATIONS OPEN, STOP & CLOSE RADIO CONTACT 6 exp PC BOARD DRWG. 1795 1 - 0.03 Amp. CIRCUIT BREAKER 14 2 - MIRI 4 FLASHING LIGHT 25 Watts FITTED WITH BIRIO A8 AERIAL 3 - PLUG-IN RADIO RECEIVER CARD ASTRO 43 SAW 4 - ELECTRONIC CONTROL BOX Elpro 6 exp OPEN CLOSE IT IS ILLUMINATED WHEN VOLTAGE IS SUPPLIED COMMON 1 2 3 4 5 - START PUSH BUTTON STOP ELECTRICAL CONNECTIONS KEYSWITCH PRIT 19 KEYSWITCH PRIT 19 6 - KEYSWITCH PRIT 19 7 - SAFETY EDGE. LOW PROFILE 8 - PHOTOCELL TRIFO 11. RECEIVER 9 - 25 Watt LAMP 10 - OPERATOR APROLI 480 11 - COVER TO PROTECT THE VALVES PIC. 16 12 - FIXING BRACKET 13 - PHOTOCELL TRIFO 11. PROJECTOR All the electrical connections to the control panel are to be made as per – Drawing 1795 – Elpro 6 exp having the following features: terminals for the keyswitch open-stop-close, photocells, safety edge, courtesy light, remote control to terminals 3 & 4 where the first pulse opens the door, the second stops it and the third re-cycles to open or close. 10 14 - RADIO TRANSMITTER ASTRO 43 TWO BUTTONS PIC. 17 11 ELECTRICAL WIRING DIAGRAM OF THE OIL-HYDRAULIC GARAGE DOOR OPERATOR APROLI 480 TO THE ELECTRONIC CONTROL PANEL GARAGE DOOR OPERATOR COMPLETE WITH ALL THE RECOMMENDED ACCESSORIES FOR A GOOD PERFORMANCE 230 VOLTS MAINS SUPPLY 1 BIRIO A8 AERIAL 2 TRANSFORMER 230 0 I.T.F. 9 3 4 6 5 7 8 9 1 R2 R1 ANT. N.A. C N.C . MOTOR RUN OPEN & CLOSE TIME R2 GND FUSE 630 mA 1° CHANNEL 2 R1 24 V OUTPUT 1 3 0 24 meth 8VA RADIO CONTROL PLUG-IN CARD SUPPORT ASTR INNESO 43 TO 0 PLUG-IN ASTRO 43 LED ON VOLTAGE SUPPLIED 4 10 CAPACITOR DIP-SWITCH ON ASTRO 43/2 RADIO RECEIVER PLUG-IN PC BOARD 1 DWELL TIME FUSES 5A 12,5 µF 2 1 2 3 4 5 6 7 8 9 11 5 12 10 11 12 13 14 15 16 17 18 COMUNE M1 230 V SINGLE-PHASE SUPPLY VOLTAGE 230 V - 25 W MAX. FLASHING LAMP 230 V - 25 W MAX. COURTESY LIGHT EARTH SINGLE-PHASE MAX. 400W ELECTRIC MOTOR MAX. PERMITTED LOAD: 1 PAIR PHOTOCELLS 1 RADIO RECEIVER 3 24 V OUTPUT A.C. LIMIT SWITCH. OPEN. N.C. LIMIT SWITCH. CLOSE. N.C. BUTTON ON THE COVER LID LIMIT SWITCH. COMMON N.O. CONTACT. OPEN SWITCH STOP CLOSE AND RADIO N.C. CONTACT. PHOTOCELLS AND SAFETY EDGE - COURTESY LIGHT FOR TWO MINUTES. ON - FLASHING LAMP. OFF - AUTOMATIC RE-CLOSING. ON - SEMI-AUTOMATIC.OFF Should more pairs of photocells be required than the recommended quantity, fit an auxiliary transformer outside the control box. NOTE WELL: THIS PANEL IS TESTED TO OPERATE GATES ONLY THROUGH FADINI ACCESSORIES. NO GUARANTEE FOR ACCESSORIES OF OTHER MAKE OR SPECIAL APPLICATIONS. OFF 6 en op 13 7 8 4 ALL OPERATIONS OPEN, STOP & CLOSE RADIO CONTACT 6 exp PC BOARD DRWG. 1795 1 - 0.03 Amp. CIRCUIT BREAKER 14 2 - MIRI 4 FLASHING LIGHT 25 Watts FITTED WITH BIRIO A8 AERIAL 3 - PLUG-IN RADIO RECEIVER CARD ASTRO 43 SAW 4 - ELECTRONIC CONTROL BOX Elpro 6 exp OPEN CLOSE IT IS ILLUMINATED WHEN VOLTAGE IS SUPPLIED COMMON 1 2 3 4 5 - START PUSH BUTTON STOP ELECTRICAL CONNECTIONS KEYSWITCH PRIT 19 KEYSWITCH PRIT 19 6 - KEYSWITCH PRIT 19 7 - SAFETY EDGE. LOW PROFILE 8 - PHOTOCELL TRIFO 11. RECEIVER 9 - 25 Watt LAMP 10 - OPERATOR APROLI 480 11 - COVER TO PROTECT THE VALVES PIC. 16 12 - FIXING BRACKET 13 - PHOTOCELL TRIFO 11. PROJECTOR All the electrical connections to the control panel are to be made as per – Drawing 1795 – Elpro 6 exp having the following features: terminals for the keyswitch open-stop-close, photocells, safety edge, courtesy light, remote control to terminals 3 & 4 where the first pulse opens the door, the second stops it and the third re-cycles to open or close. 10 14 - RADIO TRANSMITTER ASTRO 43 TWO BUTTONS PIC. 17 11 APPLICATION OF APROLI 480 ON TO A DOOR WITH UPPER TRACK, FULLY INDOOR SPECIAL GARAGE DOORS UPPER FIXING BY THE SIDE OF THE DOOR SLIDING GUIDE SAFETY SWITCH WARNING LAMP ON STARTING WITH RADIO AERIAL UPPER GUIDE 2˙500 13 CEI 400 SINGLE-PHASE IN TH E MI DDLE OF COUNTERWEIGHT 1.30 m ELECTRIC CABLE TO DANGLE FREE UPPER ROLLER FOR HORIZONTAL UPPER TRACK THE DOO R COUNTERWEIGHT 4˙000 REINFORCEMENT PLATE 100x5 mm REINFORCEMENT PLATE 100 x 5 mm PIC. 18 When very large doors are involved with a service door in the middle, it is recommended to install two operators Aproli 480 on to the door sides without connecting the shaft inner ends. Fixing dimensions and measurements are as explained before in the previous application drawings. It is also recommended to fit the service door with a safety microswitch as shown in pic.18 When two operators are required for one door, it is recommended to install the control panel “Elpro 13 CEI” and one pair of photocells Trifo 11. These are to be fixed on to the “counterweight case” 40 cm from ground level. LOWER ROLLER SLIDING IN THE LATERAL PERPENDICULAR CASING WALL FRAME PIC. 20 For the installation of Aproli 480 on to garage doors with upper track follow the same instructions as explained before; the shaft ie. the torsion fulcrum must coincide with the centre line of the door, right in the middle between upper and lower guide rollers. See Pic. 20 APPLICATION OF APROLI 480 ON A JACK-KNIFE DOOR UPPER HINGES UNSCREW BY ONE TURN TO BLEED AIR OUT OF THE OIL TANK “S” 80 / 100 mm 6 exp STEP BY STEP 2˙500 CENTER HINGES ELECTRIC CABLE LOOP LENGTH 1.30 m IMPORTANT AFTER INSTALLATION SLIDING GUIDE FOR ROLLER REINFORCEMENT PLATE 100 x 5 mm APROLI 480 3˙0 00 UNDO BY ONE TURN “S” OIL FADINI A 15 BY AGIP STICKER FITTED TO THE OIL TANK ROLLER WITH SLIDING GUIDE PIC. 19 For jack-knife doors, the same instructions apply as for single-panel doors as explained in the previous pages. Only please note that with articulated doors as the above type, it is recommended to fix the operator so that the shaft and the torsion bars are 80-100 mm below the door hinge centre line. Pic.19 12 PIC. 21 Please note, once Aproli 480 has been fixed, unscrew the air bleed screw by one turn. This screw is fitted on the cap of the oil container, where the voltage supplying cable is led to the motor. Pic.21 Should the operator «Aproli 480» be removed for maintenance or repairing tighten the screw «S» to prevent oil from coming out during handling. 13 APPLICATION OF APROLI 480 ON TO A DOOR WITH UPPER TRACK, FULLY INDOOR SPECIAL GARAGE DOORS UPPER FIXING BY THE SIDE OF THE DOOR SLIDING GUIDE SAFETY SWITCH WARNING LAMP ON STARTING WITH RADIO AERIAL UPPER GUIDE 2˙500 13 CEI 400 SINGLE-PHASE IN TH E MI DDLE OF COUNTERWEIGHT 1.30 m ELECTRIC CABLE TO DANGLE FREE UPPER ROLLER FOR HORIZONTAL UPPER TRACK THE DOO R COUNTERWEIGHT 4˙000 REINFORCEMENT PLATE 100x5 mm REINFORCEMENT PLATE 100 x 5 mm PIC. 18 When very large doors are involved with a service door in the middle, it is recommended to install two operators Aproli 480 on to the door sides without connecting the shaft inner ends. Fixing dimensions and measurements are as explained before in the previous application drawings. It is also recommended to fit the service door with a safety microswitch as shown in pic.18 When two operators are required for one door, it is recommended to install the control panel “Elpro 13 CEI” and one pair of photocells Trifo 11. These are to be fixed on to the “counterweight case” 40 cm from ground level. LOWER ROLLER SLIDING IN THE LATERAL PERPENDICULAR CASING WALL FRAME PIC. 20 For the installation of Aproli 480 on to garage doors with upper track follow the same instructions as explained before; the shaft ie. the torsion fulcrum must coincide with the centre line of the door, right in the middle between upper and lower guide rollers. See Pic. 20 APPLICATION OF APROLI 480 ON A JACK-KNIFE DOOR UPPER HINGES UNSCREW BY ONE TURN TO BLEED AIR OUT OF THE OIL TANK “S” 80 / 100 mm 6 exp STEP BY STEP 2˙500 CENTER HINGES ELECTRIC CABLE LOOP LENGTH 1.30 m IMPORTANT AFTER INSTALLATION SLIDING GUIDE FOR ROLLER REINFORCEMENT PLATE 100 x 5 mm APROLI 480 3˙0 00 UNDO BY ONE TURN “S” OIL FADINI A 15 BY AGIP STICKER FITTED TO THE OIL TANK ROLLER WITH SLIDING GUIDE PIC. 19 For jack-knife doors, the same instructions apply as for single-panel doors as explained in the previous pages. Only please note that with articulated doors as the above type, it is recommended to fix the operator so that the shaft and the torsion bars are 80-100 mm below the door hinge centre line. Pic.19 12 PIC. 21 Please note, once Aproli 480 has been fixed, unscrew the air bleed screw by one turn. This screw is fitted on the cap of the oil container, where the voltage supplying cable is led to the motor. Pic.21 Should the operator «Aproli 480» be removed for maintenance or repairing tighten the screw «S» to prevent oil from coming out during handling. 13 UNSCREW OIL-HYDRAULIC OPERATOR FOR GARAGE DOORS WITH COUNTERWEIGHTS APROLI 480 TECHNICAL SPECIFICATIONS APROLI 480 1 FIXING BRACKET “M” ® s.n.c. APROLI 480 Via Mantova, 177/A - 37053 Cerea (VR) Italy - Tel. 0442 330422 r.a. - Fax 0442 331054 2 1 DOOR OPERATOR LINEAR DESIGN 2 3 4 MOTOR APROLI 480 3 ELECTRIC TERMINAL OUTPUT 91 2 PHASE W (absor.) 330 HP (to use) 0.33 VOLTS 230 A 1.8 Rev/min. 1˙350 Hz 50 Nm 392.4 µF 12.5 Protection Standards IP 55 Max. working pressure 4 MPa (40 Bar) 4 LAMP AND LAMP REFLECTOR OIL FADINI A15 BY AGIP MADE IN ITALY 5 LAMP REFLECTOR DATA STICKER ELECTRIC MOTOR PROTECTION COVER 5 LIGHT DIFFUSION TOP COVER 7 BOTTOM COVER “A” 20 1˙610 “E” “C” 600 6 6 x2 PRESSURE SWITCH 0 35 35 86 ELECTRIC CABLE LAMP ELECTRIC MOTOR VOLTAGE SUPPLY CABLE ELECTRIC CABLE PRESSURE SWITCH 785 180 86 SAFETY EDGE WITH PRESSURE SWITCH PIC. 22 121 NEVER CUT THE ELECTRIC CABLES 7 - It is most important that the electric cables are removed from their terminals by loosening the fastening screws. Never cut the electric cables. Also make sure that the 230 V mains switch is off before removing the cables. See page 11 pic. 17. - Only by keeping to these fitting instructions a reliable installation and correct performance of the equipment can be achieved. The installation is fully under the responsibility of the installation agent, even if only Fadini products have been used as indicated in this booklet. It is advisable that the system is installed in full compliance with these instructions and in observance of the existing laws for automatic gate equipment. - The information, specifications and drawings contained herein are subject to any change that the manufacturer considers as needed. PIC. 23 OIL-HYDRAULIC PUMP ELECTRIC MOTOR Pump flow rate .....................................................................1.10 l/min. Working pressure ........................................................2 MPa (20 bar) Maximum pressure......................................................4 MPa (40 bar) Working temperature......................................................-20°C +80°C Opening time...................................................................................18 s Recommended door size...............................................................7 m2 Shaft rotation........................................................................max. 205° Hydraulic oil.....................................................oil Fadini A15 by Agip Static weight of operator........................................................10.5 Kg Weight of Aproli 480 with accessories....................................24 Kg Max. torque.............................................................................392.4 Nm Max. gate weight........................................................................150 Kg Power output...............................................................0.24 KW (0.33 HP) Supply voltage ..................................................................................230 V Frequency..........................................................................................50 Hz Absorbed power ............................................................................330 W Absorbed current.............................................................................1.8 A Capacitor........................................................................................12.5 µF Motor revolution...................................................................1˙350 r.p.m. IP Protection Standard ..................................................................IP 55 Motor rated torque.......................................................................1.3 Nm Lamp .....................................................................................230 V - 25 W Intermittent service .............................................................................S 3 PERFORMANCE Duty cycle.....................................................................................................................................18 sec. Opening – 30 sec. Dwell – 18 sec. Closing Time of one complete cycle .................................................................................................................................................................................66 sec. Complete cycles.............................................................................................................................................................................................No. 47/hour Annual cycles - 8 hours’service per day....................................................................................................................................................No.159˙000 14 15 UNSCREW OIL-HYDRAULIC OPERATOR FOR GARAGE DOORS WITH COUNTERWEIGHTS APROLI 480 TECHNICAL SPECIFICATIONS APROLI 480 1 FIXING BRACKET “M” ® s.n.c. APROLI 480 Via Mantova, 177/A - 37053 Cerea (VR) Italy - Tel. 0442 330422 r.a. - Fax 0442 331054 2 1 DOOR OPERATOR LINEAR DESIGN 2 3 4 MOTOR APROLI 480 3 ELECTRIC TERMINAL OUTPUT 91 2 PHASE W (absor.) 330 HP (to use) 0.33 VOLTS 230 A 1.8 Rev/min. 1˙350 Hz 50 Nm 392.4 µF 12.5 Protection Standards IP 55 Max. working pressure 4 MPa (40 Bar) 4 LAMP AND LAMP REFLECTOR OIL FADINI A15 BY AGIP MADE IN ITALY 5 LAMP REFLECTOR DATA STICKER ELECTRIC MOTOR PROTECTION COVER 5 LIGHT DIFFUSION TOP COVER 7 BOTTOM COVER “A” 20 1˙610 “E” “C” 600 6 6 x2 PRESSURE SWITCH 0 35 35 86 ELECTRIC CABLE LAMP ELECTRIC MOTOR VOLTAGE SUPPLY CABLE ELECTRIC CABLE PRESSURE SWITCH 785 180 86 SAFETY EDGE WITH PRESSURE SWITCH PIC. 22 121 NEVER CUT THE ELECTRIC CABLES 7 - It is most important that the electric cables are removed from their terminals by loosening the fastening screws. Never cut the electric cables. Also make sure that the 230 V mains switch is off before removing the cables. See page 11 pic. 17. - Only by keeping to these fitting instructions a reliable installation and correct performance of the equipment can be achieved. The installation is fully under the responsibility of the installation agent, even if only Fadini products have been used as indicated in this booklet. It is advisable that the system is installed in full compliance with these instructions and in observance of the existing laws for automatic gate equipment. - The information, specifications and drawings contained herein are subject to any change that the manufacturer considers as needed. PIC. 23 OIL-HYDRAULIC PUMP ELECTRIC MOTOR Pump flow rate .....................................................................1.10 l/min. Working pressure ........................................................2 MPa (20 bar) Maximum pressure......................................................4 MPa (40 bar) Working temperature......................................................-20°C +80°C Opening time...................................................................................18 s Recommended door size...............................................................7 m2 Shaft rotation........................................................................max. 205° Hydraulic oil.....................................................oil Fadini A15 by Agip Static weight of operator........................................................10.5 Kg Weight of Aproli 480 with accessories....................................24 Kg Max. torque.............................................................................392.4 Nm Max. gate weight........................................................................150 Kg Power output...............................................................0.24 KW (0.33 HP) Supply voltage ..................................................................................230 V Frequency..........................................................................................50 Hz Absorbed power ............................................................................330 W Absorbed current.............................................................................1.8 A Capacitor........................................................................................12.5 µF Motor revolution...................................................................1˙350 r.p.m. IP Protection Standard ..................................................................IP 55 Motor rated torque.......................................................................1.3 Nm Lamp .....................................................................................230 V - 25 W Intermittent service .............................................................................S 3 PERFORMANCE Duty cycle.....................................................................................................................................18 sec. Opening – 30 sec. Dwell – 18 sec. Closing Time of one complete cycle .................................................................................................................................................................................66 sec. Complete cycles.............................................................................................................................................................................................No. 47/hour Annual cycles - 8 hours’service per day....................................................................................................................................................No.159˙000 14 15 10-2005 CHECKING AND MAINTENANCE: To achieve an optimum performance and longer life of the equipment and in observance of the safety regulations, it is recommended that inspections and proper maintenance are made by qualified technicians to the whole installation ie, both the mechanical and electronic parts, as well as wiring: - Mechanical parts: maintenance every 6 months approx. - Eletronic apparatus and safety equipment: maintenance every month. IMPORTANT WARNING NOTES - Before installing the equipment carry out a Risk Analysis and fit any required device in compliance with EN 12445 and EN 12453 Safety Norms. - It is recommended to keep to the instructions here outlined. Check the specifications on the motor sticker with your mains supply. - Dispose properly of the packaging: cardboard, nylon, polystyrene, through specializing companies. - Should the operator be removed, do not cut the electric cable. This must be properly removed from the terminal board in the junction box. - Switch off the mains switch before removing the junction box cover where the electric cable is terminated. - All the system must be earthed by using the yellow/green wire, marked by its specific symbol. - It is recommended to read the regulations, suggestions and remarks quoted in the booklet “Safety Norms”. ® Made in Italy The growth of MECCANICA FADINI has always been based on the development of guaranteed products thanks to our “TOTAL QUALITY CONTROL” system which ensures constant quality standards, updated knowledge of the European Standards and compliance with their requirements, in view of an ever increasing process of improvement. The “CE” mark certifies that the operator conforms to the essential requirements of the European Directive art. 10 EEC 73/23, in relation to the manufacturer’s declaration for the supplied items, in compliance with the body of the regulations ISO 9000= UNI EN 29000. Automation in conformity to EN 12453, EN 12445 safety standards. EUROPEAN MARK CERTIFYING CONFORMITY TO THE ESSENTIAL REQUIREMENTS OF THE STANDARDS 98/37/EC • DECLARATION OF CONFORMITY • SAFETY NORMS • EN 12453, EN 12445 STANDARDS • CEI EN 60204-1 STANDARDS • WARRANTY CERTIFICATE ON THE CUSTOMER’S REQUEST ® Distributor’s box s.n.c. AUTOMATIC GATE MANUFACTURERS The manufacturers reserve the right to change the products without any previous notice and are not liable for possible damages to people and properties. Via Mantova, 177/A - 37053 Cerea (Verona) Italy - Tel. +39 0442 330422 r.a. - Fax +39 0442 331054 - e-mail: [email protected] - www.fadini.net GB INSTALLATION MANUAL ®

© Copyright 2026