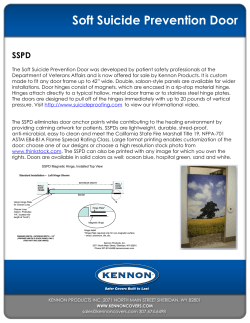

S P M ERVICE AND