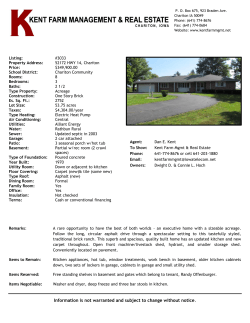

June 2014