Cleaning & Sterilization Manual Uncompromised Exposure.

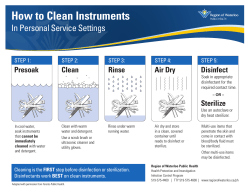

Cleaning & Sterilization Manual •PROPER CLEANING & STERILIZATION TECHNIQUES Uncompromised Exposure. CONTACT INFORMATION / CUSTOMER SERVICE: Contact your Thompson Surgical Account Manager: Toll Free: (800) 227-7543 (231) 922-0177 Shipping Address: RMA #:___________________ Thompson Surgical Instruments, Inc. 10321 East Cherry Bend Road Traverse City, MI 49684 *Indicate SO # (RMA #) on return shipments* Mailing Address: Thompson Surgical Instruments, Inc. 10170 East Cherry Bend Road Traverse City, MI 49684 SYMBOL LEGEND: EC Manufacturer REP EC Rep DO NOT Reuse Non-Sterile 0297 CE Mark Consult Instructions for Use Warnings or Precautions Biological Risks DO NOT Resterilize Keep Dry / Protect from Moisture Fragile, Handle with Care DO NOT USE if Package Damaged / Compromised IN THIS MANUAL: Section A Scope...........................................................................................................................................3 Intended Use...............................................................................................................................3 Limitations on Reprocessing........................................................................................................3 Section B Warnings......................................................................................................................................3 Precautions (Do’s and Don’ts)......................................................................................................3 Section C Processing / Reprocessing Instructions....................................................................................4-6 A. Thompson Retractor Systems and Instrument Cases............................................................4 B. Illumination Products.............................................................................................................5 C. Silicone Sleeve Accessory.....................................................................................................6 Steam Sterilization: Quick Reference Table.................................................................................7 Section D Equipment Returns: Hospital Responsibilities.............................................................................7 Product Warranty / Guarantee.....................................................................................................7 Upgrade Program........................................................................................................................7 Refurbishment Program...............................................................................................................7 References...................................................................................................................................7 2 THOMPSON SURGICAL INSTRUMENTS, INC. CLEANING & STERILIZATION MANUAL SCOPE This instruction manual provides recommended information for the cleaning and sterilization of reusable surgical retractor systems and accessories* that are manufactured and/or distributed by Thompson Surgical Instruments, Inc. Always reference our website, www.thompsonsurgical.com, for the most current revision of this manual. *Accessories refer to our retractor system components such as adapters, wrenches, instrument cases, etc. INTENDED USE Thompson Surgical retractor systems and accessories are supplied mechanically clean, but non-sterile. This manual is intended to assist health care personnel in safe handling practices, effective reprocessing, and maintenance of all Thompson Surgical Instruments, Inc.’s retractor systems and accessory families. All instruments must be inspected, cleaned, and sterilized prior to each use. LIMITATIONS ON REPROCESSING Repeat processing, according to the instructions in this manual, has minimal effect on instrument life. End of usable life for metal surgical instruments is normally determined by wear and damage due to intended surgical use. Any limitations to reprocessing cycles will be noted in this manual (Processing / Reprocessing Instructions, pages 4 - 6). CONTRAINDICATIONS Please refer to specific product instructions for use (IFU’s) or user manuals for any usage contraindications. WARNINGS PPE (Personal Protective Equipment): Should be worn, per individual hospital protocol, when handling or working with contaminated (or potentially contaminated) instruments. CJD (Creutzfeldt-Jakob Disease): Discard or destroy instruments in contact or exposed to patients with CJD, or those suspected of CJD. (Thompson Surgical does not advocate nor provide any validated instructions to eliminate risk of cross-contamination.) PRECAUTIONS (DO’S / DON’TS) DO’S DON’TS Use only soft, nylon brushes Use metal or abrasive brushes / pads Use neutral (7) or low pH chemicals Use high pH (>9) chemicals Use water-soluble instrument lube before each sterilization Use silicone lube or mineral oil Pre-clean instruments before sterilizing Sterilize without first pre-cleaning Dry instruments prior to storing Store instruments wet or semi-dry Protect instruments when storing Store instruments unprotected / piled Inspect instruments for damage Use damaged / suspect instruments www.thompsonsurgical.com THOMPSON SURGICAL INSTRUMENTS, INC. CLEANING & STERILIZATION MANUAL 3 PROCESSING / REPROCESSING INSTRUCTIONS - THOMPSON RETRACTOR SYSTEMS + INSTRUMENT CASES: (NOT including illumination products, silicone sleeve, or discontinued Adjustable Height Rail Clamp. Please note, this DOES include the new Infinite Height Rail Clamp.): Hospital must ensure operations are performed using the appropriate equipment, materials, and trained personnel. Any deviations from this manual should be evaluated for effectiveness to avoid potential adverse consequences. 1. POINT OF USE / PRE-CLEANING 1. Disassemble, loosen, or unlock instruments where possible 2. Rinse/flush instruments under cool or lukewarm running water 3. Remove excess soil while rinsing, using non-abrasive brush/cloth • Clean instruments as soon as reasonably practical, or within 30 minutes following use • Keep instruments moist and covered / wrapped until transported to Point of Use • DO NOT allow saline, blood, or other organic debris to dry on instruments NOTE: Do not completely submerge Articulating Arm central black knob during cleaning. Ensure knob is tightened during cleaning but open during sterilization. 2. CLEANING MANUAL / MECHANICAL CLEANING 1. Soak instruments in prepared enzymatic solution for 20 minutes 2. Gently scrub all surfaces, including crevices and hard-to-reach areas, with soft, nylon brush 3. Remove / rinse instruments under water for 3 minutes— thoroughly and aggressively flush difficult to reach areas 4. Submerge instruments in prepared detergent of ultrasonic unit for 10 minutes at 45-50 kHz 5. Rinse instruments in purified / distilled water for 3 minutes, or until no visible contamination remains 6. Repeat above sonication and rinse steps 7. Dry instruments using clean, lint-free cloth and/or compressed air to remove moisture from crevices and hard to reach areas • Repeat if necessary Cleaning Agents Used in Validation (prepared according to Manufacturer’s recommendations) • Enzol® by Johnson&Johnson (1 oz/gallon, using lukewarm tap water • Renu-Klenz™ by Steris (1/4 oz / gallon, using lukewarm tap water in ultrasonic unit) Final Rinse Used in Validation Reverse Osmosis / Deionized water (RO/DI) AUTOMATED CLEANING (WASHER/DISINFECTOR): 1. Rinse instruments with cold tap water for 2 minutes, ensure visible contamination is removed 2. Scrub instruments with soft brush, as necessary 3. Load instruments into automated washer/disinfector in fully extended, open positions to maximize surface exposure 4. Run washer at recommended manufacturer instructions 5. Check instruments for visible contamination following automated cycle Automated Cycle Used in Validation Phase Time (Min.) Temp. Detergent/ Concentration Pre-Wash 02:00 Cold tap water N/A Enzyme Wash 01:00 Hot tap water Enzol® by J&J (1 oz/gal) Wash 1 02:00 66ºC (151ºF) (set point) Renu-Klenz™ by Steris (1/4 oz/gal) Rinse 1 00:15 Hot tap water N/A PURW Rinse 00:10 (non-recirculation) 66ºC (151ºF) Drying 07:00 N/A 115.5ºC (240ºF) N/A 3. INSPECTION, LUBRICATION, AND TESTING 1. Carefully inspect instruments to ensure all visible contamination removed. Reassemble instruments, as necessary, to test instrument function. • • 2. Lubricate all moving mechanisms on instruments with a steam penetrable, watersoluble product after every cleaning cycle. (Such as Surgislip® or Premixslip® by Ruhof.) 3. Test action of movable parts to ensure smooth operation / uninhibited movement. Do not use any instruments that appear damaged or broken (cracked, deformed, nonfunctional, or altered) Lubricate articulated instruments after every cleaning cycle 4. STEAM STERILIZATION (see page 7 for quick table) 1. Prepare instruments for sterilization by loosening, unlocking, and disassembling all moving mechanisms or removable parts where possible 2. Arrange instruments to ensure steam sterilization can penetrate all surfaces 3. Wrap instruments or instrument tray in 2 layers of 1-ply polypropylene wrap, using sequential wrapping techniques 4. Place wrapped instruments in prevacuum steam sterilizer, following validated sterilization parameters. Steam Sterilization Parameters Validated Sterilizer Type: Prevacuum Preconditioning Pulses: 3 Minimum Temperature: 132ºC (270ºF) Full Cycle Time: 4 Minutes Minimum Dry Time: 30 Minutes Configuration for Validation Wrapped in 2 layers of 1-ply polypropylene wrap (Kimguard® KC600, by Kimberly Clark Healthcare) using sequential wrapping techniques • Total weight of wrapped instruments or tray may not exceed 11.4kg (25 pounds) (Weight gain, post-sterilization must not exceed 3% of 11.4kg ( (25 pounds) 5. STORAGE AND USE If package integrity is compromised or suspect, repeat Processing / Reprocessing Instructions (All Sections: 1 - 4) STORAGE Store sterile, packaged instruments in a limited access area that is well-ventilated, protected from contaminants, and dry USE Carefully examine sterile instrument packaging prior to use, ensuring package integrity is maintained 4 THOMPSON SURGICAL INSTRUMENTS, INC. CLEANING & STERILIZATION MANUAL PROCESSING / REPROCESSING INSTRUCTIONS - ILLUMINATION PRODUCTS: Hospital must ensure operations are performed using the appropriate equipment, materials, and trained personnel. Any deviations from this manual should be evaluated for effectiveness to avoid potential adverse consequences. 1. POINT OF USE / PRE-CLEANING (ILLUMINATION PRODUCTS ONLY) 1. Gently remove Lite Clip (where applicable) from illumination product; open / unlock joint (where applicable) 2. Distal light emitting end(s) pointed downward, rinse under warm (not hot) tap water 3. Use soft brush to gently scrub instrument while rinsing (at least 1 minute) 4. Rinse instruments and actuate joint, ensuring all areas are accessed • Clean instruments as soon as reasonably practical, or within 30 minutes following use Allow instruments to cool (if hot or warm) Keep away from flammables • Never soak / avoid cold rinse • • Do not slide Lite Clip from distal end; carefully and slowly push off from side. Handle illumination products with care; treat glass surfaces / fiber cables as fine, optical devices. When removing Lite Clips, do so carefully and slowly. Do not “yank” or use tools to pry them off to avoid breakage. 2. MANUAL CLEANING ONLY (ILLUMINATION PRODUCTS ONLY) MANUAL CLEANING 1. Prepare enzymatic solution, according to manufacturer’s recommendations 2. Dip soft bristled brush into solution, then gently scrub instrument until all visible soil is removed 3. Pay extra attention to hidden / hard to reach areas of instrument 4. Rinse under warm, gently running tap water - distal end pointed down 5. REPEAT STEPS 2 - 4 6. Dry instruments using clean, soft, and lint free cloth 7. Visually inspect cloth to ensure no visible soil remains Materials Used in Validation (Xenon illumination products) • Enzol® by Johnson&Johnson (1 oz / gallon, using warm tap water) • M-16: soft bristled brush Never immerse or soak illumination products. Automated / sonification NOT allowed. If visible or residual soil is found, REPEAT entire Manual Cleaning process. 3. INSPECTION, LUBRICATION, AND TESTING (ILLUMINATION PRODUCTS ONLY) 1. Carefully inspect instruments to ensure all visible contamination removed and no instrument damage. • • 2. Lubricate joint with a steam penetrable, watersoluble product after every cleaning cycle. (Such as Surgislip® or Premixslip® by Ruhof.) 3. Test articulation of joint to ensure smooth operation / uninhibited movement. Do not use if cable shows signs of damage (punctures or kinks, for example) or if any parts become loose (light emitting pieces). Replacement recommended when 30% or more of fibers are no longer working. 4. STEAM STERILIZATION (ILLUMINATION PRODUCTS ONLY) (see page 7 for quick table) 1. Prepare instruments for sterilization by ensuring joint is open / unlocked (where applicable) and disassemble Lite Clip (where applicable) from illumination product 2. Wrap illumination product, per product (Xenon or LED) Test Article Configuration, as indicated in validated steam sterilization 3. Place wrapped / sealed instruments in prevacuum steam sterilizer, following validated sterilization parameters, per illumination product (Xenon or LED) Xenon illumination products will survive a MAXIMUM of 100 cycles prevacuum steam sterilization. LED illumination products will survive a MINIMUM of 100 cycles prevacuum steam sterilization. Validated Steam Sterilization for XENON Illumination Products Sterilizer Type: Prevacuum Preconditioning Pulses: 3 Minimum Temperature: 132ºC (270ºF) Full Cycle Time: 3 Minutes Minimum Dry Time: 30 Minutes Validated Steam Sterilization for LED Illumination Products Sterilizer Type: Prevacuum Preconditioning Pulses: 3 Minimum Temperature: 132ºC (270ºF) Full Cycle Time: 4 Minutes Minimum Dry Time: 20 Minutes Xenon Test Article Configuration Individually wrapped in 2 layers of 1-ply polypropylene wrap (Kimguard® KC600, by Kimberly Clark Healthcare) using sequential envelope folding techniques. Xenon ilumination products (Lite Wand, Lite Clip) were sterilized inside Lite Wand Instrument Case. LED Test Article Configuration Individually placed/sealed in SPSmedical Self-Seal Pouch along with STEAMPlus™ Integrator. Placed in pouch divider for processing. 5. STORAGE AND USE If package integrity is compromised or suspect, repeat Processing / Reprocessing Instructions (All Sections: 1 - 4) USE STORAGE Store sterile, packaged instruments in a limited access area that is well-ventilated, protected from contaminants, and dry www.thompsonsurgical.com Carefully examine sterile instrument packaging prior to use, ensuring package integrity is maintained THOMPSON SURGICAL INSTRUMENTS, INC. CLEANING & STERILIZATION MANUAL 5 PROCESSING / REPROCESSING INSTRUCTIONS - SILICONE SLEEVE ACCESSORY: Hospital must ensure operations are performed using the appropriate equipment, materials, and trained personnel. Any deviations from this manual should be evaluated for effectiveness to avoid potential adverse consequences. 1. POINT OF USE / PRE-CLEANING (SILICONE SLEEVE ACCESSORY ONLY) 1. Gently rinse Silicone Sleeve under warm / lukewarm water 2. Ensure any visible debris is removed from inner / outer surfaces of sleeve Silicone Sleeves must be clean and kept moist from pre-clean through sterilization. 2. MANUAL CLEANING ONLY (SILICONE SLEEVE ACCESSORY ONLY) MANUAL CLEANING 1. Prepare enzymatic solution, according to manufacturer’s recommendations 2. Immerse or soak sleeve in solution, while gently using clean, non-abrasive cloth to wipe any residual debris 3. Rinse sleeve under warm running water If visible or residual soil is found, REPEAT entire Manual Cleaning process. 3. INSPECTION (SILICONE SLEEVE ACCESSORY ONLY) Carefully inspect Silicone Sleeve to ensure all visible contamination removed and no tears or damage present. 4. STEAM STERILIZATION (SILICONE SLEEVE ACCESSORY ONLY) (see page 7 for quick table) 1. Gently wrap Silicone Sleeve in muslin cloth or sterilization paper 2. Place in clean, open tray 3. Place wrapped instruments in prevacuum steam sterilizer, following validated sterilization parameters. Steam Sterilization Parameters Validated Sterilizer Type: Prevacuum Preconditioning Pulses: 3 Minimum Temperature: 132ºC (270ºF) Full Cycle Time: 3 Minutes Minimum Dry Time: 30 Minutes Do not crush or compress Silicone Sleeve during sterilization. Ensure cylinder shape is maintained. 5. STORAGE AND USE • • Resterilizable Disposable STORAGE Silicone sleeves may remain in storage for up to 5 years. (Refer to expiration date on product label.) USE • • Silicone Sleeve must be discarded after one surgical use. Silicone Sleeve may be altered to patient size. 6 THOMPSON SURGICAL INSTRUMENTS, INC. CLEANING & STERILIZATION MANUAL STEAM STERILIZATION: QUICK REFERENCE TABLE PRODUCT MIN. CYCLE TEMP MIN. EXPOSURE TIME MIN. DRY TIME CYCLE LIFE Thompson Retractor Systems and Instrument Cases (incl. IHRC) 132ºC (270ºF) 4 Minutes 30 Minutes Unlimited Adjustable Height Rail Clamp (discontinued) 132ºC (270ºF) 10 Minutes 30 Minutes Unlimited MIS Articulating Arm (Spine) Max of: 134ºC (273ºF) 5 Minutes 30 Minutes Unlimited Silicone Sleeve Accessory 132ºC (270ºF) 3 Minutes 30 Minutes N/A Illumination Products and Cases: XENON 132ºC (270ºF) 3 Minutes 30 Minutes 100 MAXIMUM Illumination Products and Cases: LED 132ºC (270ºF) 4 Minutes 20 Minutes 100 MINIMUM Note: If sterilizing MIS Articulating Arm with MIS Retractor Lite LED, use higher exposure time of 5 minutes. (Dependent on # of cycles sterilized in this configuration, LED Lite cycle life could decrease from 100 max to 80 max.) EXCEPTIONS (NON-STERILE PRODUCTS): • Stay Put Arm (42137H) Arm must be draped for sterile use • LED Light Source (LLS-2000) May only be disinfected/wiped down using cleaning agents compliant with other electrical medical equipment. NEVER IMMERSE IN WATER OR EXPOSE TO LIQUID/EXCESS MOISTURE. EQUIPMENT RETURNS: HOSPITAL RESPONSIBILITIES ALL loaner and trial equipment returns must be fully reprocessed before shipping to Thompson Surgical Instruments, Inc. (10321 East Cherry Bend Road, Traverse City, MI 49684) Hospital must indicate cleaning / sterilization of instruments on return (RMA) packaging. Prevent damage of returned equipment: - ALWAYS place parts in designated holders / spaces when using organized instrument cases - NEVER ship Elite II Rail Clamps / Infinite Height Rail Clamps / Power Rail Clamps inside instrument cases; MUST package separately PRODUCT WARRANTY / GUARANTEE Thompson Surgical Instruments, Inc. warrants all instruments* free from defects in material or workmanship for the life of the instrument. Warranty (guarantee) void if product failure resulted from accident, abuse, misapplication, negligence, or if the product has been damaged, altered, or repaired outside of Thompson Surgical’s facility. - Malleable blades carry a 2 year guarantee against defects in both material and workmanship - Illumination Products Xenon products carry a 60 day guarantee LED products carry a 1 year guarantee UPGRADE PROGRAM Discounts are given on the exchange of old components, or exchange of another brand of retractors, toward the purchase of new updated designs. REFURBISHMENT PROGRAM Most Thompson Surgical components and accessories may be sent to our facility and refurbished to like-new quality. Please call 800.227.7543 or visit our website at www.thompsonsurgical.com for details and pricing. Repair of obsolete or “beyond repair” products may require a replacement purchase. Not all products are eligible for refurbishment. Contact your Account Manager for details. REFERENCES AAMI TIR12 “Designing, testing, and labeling reusable medical devices for reprocessing in health care facilities: A guide for medical device manufacturers” AAMI TIR30 “A compendium of processes, materials, test methods, and acceptance criteria for cleaning reusable medical devices” FDA “Draft Guidance for Industry and FDA Staff: Processing / Reprocessing Medical Devices in Health Care Settings: Validation Methods and Labeling” ISO 15223 “Medical devices – Symbols to the used with medical device labels, labelling, and information to be supplied” ISO 17664 “Sterilization of medical devices – information to be provided by the manufacturer for the processing of resterilizable medical devices” www.thompsonsurgical.com THOMPSON SURGICAL INSTRUMENTS, INC. CLEANING & STERILIZATION MANUAL 7 Rev C 060314 ster0614 10170 East Cherry Bend Road Traverse City, Michigan 49684 phone: 231.922.0177 fax: 231.922.0174 thompsonsurgical.com EC REP Emergo Europe Molenstraat 15 2513 BH, The Hague THE NETHERLANDS 0297 © 2014 Thompson Surgical Instruments, Inc. Traverse City, Michigan. Printed in U.S.A. ® The “T-Circle” logo is a Registered Trademark of Thompson Surgical Instruments, Inc. Made in the USA

© Copyright 2026