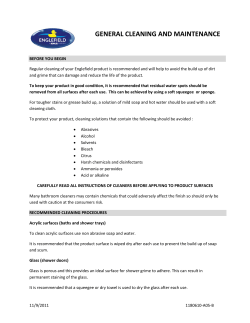

3-A Sanitary Standards General Requirements T-00-00