Project Manual For CHERRY CREEK SHOPPING CENTER

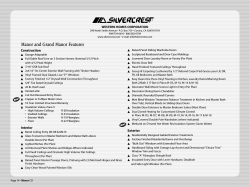

Project Manual For CHERRY CREEK SHOPPING CENTER NORTH PAD REDEVELOPMENT 2900 E. First Avenue, Denver, Colorado July 24, 2014 Bulletin #3 – RH ARCHITECT OF RECORD Hobbs + Black Associates Inc. 100 N. State Street Ann Arbor, Michigan 48104 Phone: (734) 663-4189 H+B Project Number: 13-422 THIS PAGE INTENTIONALLY LEFT BLANK CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 TABLE OF CONTENTS PAGES TABLE OF CONTENTS TOC 1 thru 4 011219 012500 012600 012613 012900 013113 013119 013216 013323 013323.1 014216 014523 014550 015000 016000 017123 017329 017423 017700 017829 017836 017839 1 thru 2 1 thru 4 1 thru 2 1 thru 2 1 thru 4 1 thru 3 1 thru 3 1 thru 4 1 thru 4 1 thru 2 1 thru 4 1 thru 7 1 thru 18 1 thru 9 1 thru 5 1 thru 2 1 thru 3 1 thru 2 1 thru 3 1 only 1 only 1 thru 4 032000R 033000R 033543R 1 thru 6 1 thru 20 1 thru 8 042200R 047200R 1 thru 13 1 thru 7 DIVISION 00 – PROCUREMENT AND CONTRACTING REQUIREMENTS Sections Separately Issued by Castle Building Group DIVISION 01 - GENERAL REQUIREMENTS 011219 012500 012600 012613 012900 013113 013119 013216 013323 013323.1 014216 014523 014550 015000 016000 017123 017329 017423 017700 017829 017836 017839 Contract Interface Substitution Procedures Contract Modification Procedures Requests for Interpretation (RFI) Payment Procedures Project Coordination Project Meetings Construction Progress Schedule Shop Drawings, Product Data, and Samples Agreement to Use Digital Data Definitions Quality Control Testing and Inspection Services Structural Testing, Inspection, and Quality Assurance Temporary Facilities and Controls Common Product Requirements Field Engineering Cutting and Patching Final Clearing Closeout Procedures Final Site Survey Warranties Project Record Documents DIVISION 02 – NOT USED DIVISION 03 – CONCRETE 032000 033000 033543 Concrete Reinforcing Cast-in-Place Concrete Diamond Polished Concrete Finishing DIVISION 04 – MASONRY 042200 047200 Concrete Unit Masonry Cast Stone Masonry DIVISION 05 – METALS Table of Contents – RH TOC - 1 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 051200 051213 053100 054000 055000 055113 055213 Structural Steel Framing Architecturally Exposed Structural Steel Framing Steel Decking Lightgage Metal Framing (Cold-Formed Framing) Metal Fabrications Metal Pan Stairs Pipe and Tube Railings H+B Project No. 13-422 July 24, 2014 051200R 051213R 053100R 054000R 055000R 055113R 055213R 1 thru 15 1 thru 6 1 thru 9 1 thru 6 1 thru 13 1 thru 8 1 thru 8 061053R 061600R 1 thru 7 1 thru 3 071113R 071326R 071900R 072100R 072500R 074113R 075216R 1 thru 3 1 thru 5 1 thru 4 1 thru 5 1 thru 6 1 thru 12 1 thru 12 076200R 077100R 077200R 077253R 077620R 078100R 078123R 078413R 078446R 079200R 1 thru 11 1 thru 10 1 thru 7 1 thru 2 1 thru 4 1 thru 8 1 thru 8 1 thru 6 1 thru 4 1 thru 10 081113R 081115R 082120R 081315R 1 thru 8 1 thru 9 1 thru 5 1 thru 6 084110R 085200R 086300R 1 thru 8 1 thru 5 1 thru 10 DIVISION 06 – WOOD, PLASTICS, AND COMPOSITES 061053 061600 Miscellaneous Rough Carpentry Sheathing DIVISION 07 – THERMAL AND MOISTURE PROTECTION 071113 071326 071900 072100 072500 074113 075216 076200 077100 077200 077253 077620 078100 078123 078413 078446 079200 Bituminous Dampproofing Self-Adhering Sheet Waterproofing Water Repellents Thermal Insulation Weather Barriers Standing Seam Metal Roof Panels Styrene-Butadiene-Styrene (SBS) Modified Bituminous Membrane Roofing Sheet Metal Flashing and Trim Roof Specialties Roof Accessories Snow Guards Roof Pavers and Pedestals Sprayed-on Fire Protection Intumescent Fireproofing Penetration Firestopping Fire-Resistive Joint Systems Joint Sealants DIVISION 08 – OPENINGS 081113 081115 082120 081315 084110 085200 086300 Exterior Hollow Metal Doors and Frames Interior Hollow Metal Doors and Frames Aluminum Clad Wood Doors Custom Steel Doors and Frames [Section first issued with Bull. 3] Aluminum Entrances Aluminum Windows Metal-Framed Skylights Table of Contents – RH TOC - 2 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 087100 088000 Door Hardware [Section re-issued with Bull. 3] Glass and Glazing H+B Project No. 13-422 July 24, 2014 087100R 1 thru 17 088000R 1 thru 11 092116R 092200R 092216R 092900R 099113R 1 thru 5 1 thru 5 1 thru 6 1 thru 7 1 thru 7 142100R 1 thru 20 210517R 211200R 1 thru 4 1 thru 12 220000R 220500R 220513R 220516R 220519R 220523R 220529R 220553R 220700R 221116R 221119R 221316R 221319R 221413R 221423R 1 thru 17 1 thru 8 1 thru 2 1 thru 3 1 thru 5 1 thru 7 1 thru 10 1 thru 4 1 thru 12 1 thru 14 1 thru 5 1 thru 9 1 thru 6 1 thru 6 1 thru 6 DIVISION 09 – FINISHES 092116 092200 092216 092900 099113 Gypsum Board Shaft Wall Assemblies Portland Cement Plaster Non-Structural Metal Framing Gypsum Board Exterior Painting [Section re-issued with Bull. 3] DIVISION 10 THRU 13 – NOT ISSUED DIVISION 14 – CONVEYING SYSTEMS 142100 Electric Traction Elevators DIVISION 15 THRU 20 – NOT USED DIVISION 21 – FIRE SUPPRESSION 210517 211100 Sleeves and Sleeve Seals for Fire Suppression Piping Fire Suppression Standpipes DIVISION 22 – PLUMBING 220000 220500 220513 220516 220519 220523 220529 220553 220700 221116 221119 221316 221319 221413 221423 General Plumbing Requirements Common Work Results for Plumbing Common Motor Requirements for Plumbing Equipment Expansion Fittings and Loops for Plumbing Piping Meters and Gages for Plumbing Piping General-Duty Valves for Plumbing Piping Hangers and Supports for Plumbing Piping Equipment Identification for Plumbing Piping and Equipment Plumbing Insulation Domestic Water Piping Domestic Water Piping Specialties Sanitary Waste and Vent Piping Sanitary Waste Piping Specialties Facility Storm Drainage Piping Storm Drainage Piping Specialties Table of Contents – RH TOC - 3 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 DIVISION 23 – HEATING, VENTILATING AND AIR CONDITIONING 230000 230500 230513 230523 230529 230553 230593 230700 231123 233113 233300 233416 233713 237433 238000 238239 General Mechanical Requirements Common Work Results for HVAC Common Motor Requirements for HVAC Equipment General-Duty Valves for HVAC Piping Hangers and Supports for HVAC Piping Equipment Identification for HVAC Piping and Equipment Testing, Adjusting and Balancing for HVAC HVAC Insulation Facility Natural-Gas Piping Metal Ducts Air Duct Accessories Centrifugal HVAC Fans Diffusers, Registers, and Grilles Energy Recovery Ventilating Units Variable Refrigerant Flow System Equipment Electric Heaters 230000R 230500R 230513R 230523R 230529R 230553R 230529R 230700R 231123R 233113R 233300R 233416R 233713R 237433R 238000R 238239R 1 thru 17 1 thru 8 1 thru 3 1 thru 5 1 thru 7 1 thru 6 1 thru 4 1 thru 14 1 thru 12 1 thru 12 1 thru 8 1 thru 8 1 thru 5 1 thru 8 1 thru 12 1 thru 8 260500R 260510R 260519R 260526R 260529R 260533R 260553R 262220R 262413R 262416R 262726R 262813R 262819R 264313R 266013R 1 thru 7 1 thru 2 1 thru 4 1 only 1 thru 2 1 thru 6 1 thru 2 1 thru 3 1 thru 6 1 thru 3 1 thru 4 1 thru 2 1 thru 2 1 thru 5 1 thru 4 DIVISION 24 AND 25 – NOT USED DIVISION 26 – ELECTRICAL 260500 260510 260519 260526 260529 260533 260553 262220 262413 262416 262726 262813 262819 264313 266013 Common Work Results for Electrical Electrical Remodeling Provisions Low-Voltage Electrical Power Conductors and Cables Grounding and Bonding for Electrical Systems Hangers and Supports for Electrical Systems Raceway and Boxes for Electrical Systems Identification for Electrical Systems Low-Voltage Transformers Switchboards Panelboards Wiring Devices Fuses Enclosed Switches Transient Voltage Surge Suppression (TVSS) Roof Gutter and Downspout Heat Trace System DIVISIONS 27 THRU 31 – NOT ISSUED DIVISION 33 – LANDSCAPE 321440.14 Flagstone Paving (Dry Set) 321440.14R 1 thru 5 END OF TABLE OF CONTENTS - RH Table of Contents – RH TOC - 4 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 SECTION 081315 - CUSTOM STEEL DOORS AND FRAMES PART 1 - GENERAL 1.1 SUMMARY A. Section Includes: Custom steel doors and frames at the high exterior door openings on the First Level, to match the appearance of the aluminum clad stile and rail wood doors and frames at the upper levels. B. Related Documents: Refer to: 1. 2. 3. 4. 5. 1.2 Division 00 - Procurement and Contracting Requirements, and Division 01 - General Requirements, are hereby made part of this Section. Division 05 Sections “Structural Steel Framing” and “Cold-Formed Framing Units” for exterior wall framing. Section 082120R, Aluminum Clad Stile and Rail Wood Doors. Section 087100R, Door Hardware, for hardware other than hinges and sills. Section 088000R, Glass and Glazing, for insulating glass. PERFORMANCE REQUIREMENTS A. Delegated Design: Design the custom steel doors and frames, including comprehensive engineering analysis by a qualified professional engineer, using performance requirements and design criteria indicated. B. Wind Loads: As indicated on the Drawings. C. Deflection of Framing Members: 1. Deflection Normal to Wall Plane: Edge of glass in a direction perpendicular to glass plane shall not exceed the following, whichever is less: a. b. c. 2. Deflection Parallel to Glazing Plane: Limited to the following, whichever is smaller: a. b. 1.3 L/175 of the glass edge length for each individual glazing lite, per International Building Code recommendations for framing members supporting glass. 1/175 of clear span, per AAMA TIR-A11 recommendations 3/4 inch edge deflection of individual glazing lites. L/360 of clear span or 1/8 inch. An amount not exceeding that which reduces glazing bite to less than 75 percent of design dimension and that which reduces edge clearance between framing members and glazing or other fixed components directly below them to less than 1/8 inch and clearance between members and operable units directly below them to less than 1/16 inch. SUBMITTALS A. General: Submit in accordance with Section 013323. CUSTOM STEEL DOORS AND FRAMES 081315R - 1 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 B. Product Data: For each type of product indicated. C. Shop Drawings: Indicate location, size and hand of each door; elevation of each kind of door; Construction details not covered in Product Data; and other pertinent data. D. Samples for verification: 1. For each type of exposed finish required, prepared on samples of note less than 6” typical. 2. Sample of specified muntin, showing welded intersections and glazing beads. 3. Color sample of finish E. Delegated-Design Submittal: Indicated to comply with performance requirements and design criteria, including analysis data signed and sealed by the qualified professional engineer responsible for their preparation. F. Warranties: Submit 10 year warranty from the date of project opening for the door and frame assembly. 1.4 INFORMATIONAL SUBMITTALS A. 1.5 Product Test Reports: For each type of custom steel door and frame assembly, for tests performed by a quality testing agency. QUALITY ASSURANCE A. Quality Standard: Comply with Custom Hollow Metal Door standards. B. Installation of doors shall be done by experienced door installers. C. Allowable tolerances: Size dimensions + 1/16” D. Quality of Power of 5 finishing process shall meet or exceed the following ASTM designations: 1. ASTM D714 – Paint Blistering Test 2. ASTM D4585 – Humidity Test 3. ASTM B117 – Salt Spray (Fog) Test 4. ASTM D1654 – Painted Products in Corrosive Environments 5. ASTM G85 – Cyclic Fog/Dry Test (Prohesion) 6. ASTM D5894 – Salt Fog/ UV Painted Metal 7. ASTM D4541 – Pull off Strength of Coating Test CUSTOM STEEL DOORS AND FRAMES 081315R - 2 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 1.6 H+B Project No. 13-422 July 24, 2014 DELIVERY, STORAGE, AND HANDLING A. Delivery: Deliver materials to site undamaged in manufacturer’s or sales branch’s original, unopened containers and packaging, with labels clearly identifying manufacturer and product name. Include installation instructions. B. Storage: Store materials in an upright position, off ground, under cover, and protected from weather, direct sunlight, and construction activities. C. Handling: Protect materials and finish during handling and installation to prevent damage. PART 2 - PRODUCTS 2.1 MANUFACTURERS A. Manufacturers: following: 1. 2. 2.2 Subject to compliance with requirements, provide products by one of the Hope’s Windows, Inc., Jamestown, New York, 716.665.5124, www.hopeswindows.com. Custom steel entrance fabricators, as approved by architect. CUSTOM STEEL FRENCH HINGED DOORS A. Hinged French Doors: Pairs of steel French doors, out swinging, installed in frames, and matching the stile, rail and mullion profiles of the clad aluminum doors on the upper levels, in 6’0” by 12’-1” openings, unless otherwise indicated. Basis of Design: Hope’s 5000 Series in custom color to match architect’s sample. 2.3 1. Frame: Overall depth 4”, unless otherwise indicated on the documents. 2. Hinges: Corrosion-resistant leaves, with wear-resistant hinge bushings and stainless steel pin and decorative cap. At least four hinges per door panel. 3. Sill: As indicated in the door schedule. anodized. 4. Finish: Custom factory applied finish - color to match architect’s sample Prefinished extruded aluminum with bronze MATERIALS A. Door and frames shall be manufactured from 12 gauge galvanized steel. B. Muntins 1. True Divided Lite Muntins: a. Muntins shall be manufactured from solid hot-rolled steel, size to be determined by the design. CUSTOM STEEL DOORS AND FRAMES 081315R - 3 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 b. Glazing rebate surfaces must be perpendicular to the stem of this profile. Rebate surfaces that are tapered will not be acceptable. c. C. Profile to match architects sample. Glazing System Glazing: As specified in Section 088000, Glazing. D. Door Hardware 1. As specified in 087100R Door Hardware E. Glazing beads shall be extruded aluminum alloy 6063-T5 with a minimum thickness of .062 inches. F. Hardware reinforcements shall be 7, 10 or 12 gauge galvanized steel to suit specified hardware. G. All hardware for trim, covers, anchoring, weather bars, water dams, etc. shall be non-ferrous brass or stainless steel. Glazing bead screws permitted to be plated steel. 2.4 FABRICATION A. Fabricate steel doors in accordance with approved shop drawings. B. Perimeter frame corners shall be coped and fully welded for maximum strength and weather tightness with face welds dressed smooth. C. Head and jamb door stops shall be an integral portion of the frame with a 5/8” high rebate. D. Door leaves shall have inside and outside skins laser cut from single sheet and joined at the door style. E. Doors and door frames shall be mortised, reinforced, drilled and tapped to receive specified hardware. F. Muntins 1. F. True divided lite muntins shall be coped and welded to the perimeter frame. Muntin intersections shall be slotted, cross notched and welded. All interior muntin joints shall be face welded and ground smooth. Glazing 1. All doors shall be designed for inside or outside glazing. 2. Provide replacement continuous snap-in glazing beads to suit the glass as specified. 3. Glazing beads shall be cut and shop fitted to each glass lite prior to shipment. 4. Manufacturer to provide correct glazing wedge and tape in accordance with the tested assembly. CUSTOM STEEL DOORS AND FRAMES 081315R - 4 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 2.5 H+B Project No. 13-422 July 24, 2014 FACTORY FINISHING A. Cleaning 1. B. All hot-rolled steel profiles must be acid pickled as defined by SSPC – SP8 to ensure a pristine, white metal substrate prior to fabrication. Factory Finish: Clean, pretreat and apply manufacturer’s standard ultrathane polyurethane top coat with epoxy primer. 1. Color: Match Architect’s Sample TOLERANCES A. Doors shall accommodate the following opening tolerances: 1. 2. 3. 2.6 Vertical Dimensions between High and Low Points: Plus 1/8 inch, minus 0 inch. Width Dimensions: Plus 1/8 inch, minus 0 inch. Building Columns or Masonry Openings: Plus or minus 1/8 inch from plumb. INSTALLATION ACCESSORIES A. Flashing/Sealant Tape: Aluminum-foil-backed butyl window and door flashing tape, UV resistant.. Maximum Total Thickness: 0.013 inch. Verify sealant compatibility with sealant manufacturer. B. Interior Insulating – Foam Sealant: window and door foam sealant. C. Exterior Perimeter Sealant: “Pella Window and Door Installation Sealant” or equivalent high quality, multi-purpose sealant as specified in the joints sealant section. Low-expansion, low-pressure polyurethane insulating PART 3 - EXECUTION 3.1 EXAMINATION A. 3.2 Examine areas to receive doors. Notify Architect of conditions that would adversely affect installation or subsequent use. Do not proceed with installation until unsatisfactory conditions are corrected. PREPARATION A. Remove welded-in shipping spreaders installed at factory. Restore exposed finish by grinding, filling, and dressing, as required to make repaired area smooth, flush and invisible on exposed faces. B. Drill and tap doors and frames to receive nontemplated, mortised, and surface-mounted door hardware. CUSTOM STEEL DOORS AND FRAMES 081315R - 5 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 3.3 H+B Project No. 13-422 July 24, 2014 INSTALLATION A. Install doors and frames in accordance with manufacturer’s instructions and approved shop drawings. B. Install doors to be weather-tight and freely operating. C. Maintain alignment with adjacent work. D. Secure assembly to framed openings, plumb and square, without distortion. E. Integrate door system installation with exterior water-resistant barrier using flashing/sealant tape. Apply and integrate flashing/sealant tape with water-resistant barrier using watershed principles in accordance with door manufacturer’s instructions. F. Place interior seal around door perimeter to maintain continuity of building thermal and air barrier using insulating-foam sealant. G. Seal door to exterior wall cladding with sealant and related backing materials at perimeter of assembly H. Leave doors closed and locked with shoot bolts extended. 3.4 CLEANING A. Clean doors, frames and glass in accordance with Division 1 requirements. B. Do not use harsh cleaning materials or methods that would damage finish. C. Remove labels and visible markings. 3.5 PROTECTION A. Protect installed doors and frames to ensure that, except for normal weathering, doors will be without damage or deterioration at time of substantial completion. END OF SECTION 081315R CUSTOM STEEL DOORS AND FRAMES 081315R - 6 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 SECTION 087100 – DOOR HARDWARE PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this Section. SUMMARY A. Section Includes: 1. Mechanical door hardware for the following: a. Swinging doors. B. Related Sections: 1. Section 081113 "Exterior Hollow Metal Doors and Frames". 2. Section 081115 “Interior Hollow Metal Doors and Frames” for astragals provided as part of labeled fire-rated assemblies and per door silencers provided as part of hollow-metal frames. 3. Section 082120 “Aluminum Clad Wood Doors” per installation / coordination of entrance door hardware, including cylinders. 4. Section 084110 "Aluminum Entrances" for installation of entrance door hardware, including cylinders. 1.3 ACTION SUBMITTALS A. Product Data: For each type of product indicated. Include construction and installation details, material descriptions, dimensions of individual components and profiles, and finishes. B. Other Action Submittals: 1. Door Hardware Schedule: Prepared by or under the supervision of Installer, detailing fabrication and assembly of door hardware, as well as installation procedures and diagrams. Coordinate final door hardware schedule with doors, frames, and related work to ensure proper size, thickness, hand, function, and finish of door hardware. a. b. c. Submittal Sequence: Submit door hardware schedule concurrent with submissions of Product Data, Samples, and Shop Drawings. Coordinate submission of door hardware schedule with scheduling requirements of other work to facilitate the fabrication of other work that is critical in Project construction schedule. Format: Comply with scheduling sequence and vertical format in DHI's "Sequence and Format for the Hardware Schedule." Double space entries, and number and date each page. Content: Include the following information: 1) DOOR HARDWARE Identification number, location, hand, fire rating, size, and material of each door and frame. 087100R - 1 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 2) 3) 4) 5) 6) 7) 8) C. 1.4 H+B Project No. 13-422 July 24, 2014 Locations of each door hardware set, cross-referenced to Drawings on floor plans and to door and frame schedule. Complete designations, including name and manufacturer, type, style, function, size, quantity, function, and finish of each door hardware product. Description of electrified door hardware sequences of operation and interfaces with other building control systems. Fastenings and other pertinent information. Explanation of abbreviations, symbols, and codes contained in schedule. Mounting locations for door hardware. List of related door devices specified in other Sections for each door and frame. Keying Schedule: Prepared by or under the supervision of Installer, detailing Owner's final keying instructions for locks. Include schematic keying diagram and index each key set to unique door designations that are coordinated with the Contract Documents. INFORMATIONAL SUBMITTALS A. Qualification Data: For Architectural Hardware Consultant. B. Product Certificates: For electrified door hardware, from the manufacturer. 1. Certify that door hardware approved for use on types and sizes of labeled fire-rated doors complies with listed fire-rated door assemblies. C. Product Test Reports: For compliance with accessibility requirements, based on evaluation of comprehensive tests performed by manufacturer and witnessed by a qualified testing agency, for door hardware on doors located in accessible routes. D. Warranty: Special warranty specified in this Section. 1.5 CLOSEOUT SUBMITTALS A. 1.6 Maintenance Data: For each type of door hardware to include in maintenance manuals. Include final hardware and keying schedule. QUALITY ASSURANCE A. Installer Qualifications: Supplier of products and an employer of workers trained and approved by product manufacturers and an Architectural Hardware Consultant who is available during the course of the Work to consult with Contractor, Architect, and Owner about door hardware and keying. 1. Warehousing Facilities: In Project's vicinity. 2. Scheduling Responsibility: Preparation of door hardware and keying schedules. 3. Engineering Responsibility: Preparation of data for electrified door hardware, including Shop Drawings, based on testing and engineering analysis of manufacturer's standard units in assemblies similar to those indicated for this Project. B. Architectural Hardware Consultant Qualifications: A person who is experienced in providing consulting services for door hardware installations that are comparable in material, design, and extent to that indicated for this Project and who is currently certified by DHI as follows: 1. For door hardware, an Architectural Hardware Consultant (AHC) or Architectural Openings Consultant (AOC). DOOR HARDWARE 087100R - 2 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 C. Source Limitations: Obtain each type of door hardware from a single manufacturer. D. Fire-Rated Door Assemblies: Where fire-rated door assemblies are indicated, provide door hardware rated for use in assemblies complying with NFPA 80 that are listed and labeled by a qualified testing agency, for fire-protection ratings indicated, based on testing at positive pressure according to NFPA 252 or UL 10C, unless otherwise indicated. E. Smoke- and Draft-Control Door Assemblies: Where smoke- and draft-control door assemblies are required, provide door hardware that meet requirements of assemblies tested according to UL 1784 and installed in compliance with NFPA 105. 1. Air Leakage Rate: Maximum air leakage of0.3 cfm/sq. ft. (3 cu. m per minute/sq. m) at the tested pressure differential of 0.3-inch wg (75 Pa) of water. F. Means of Egress Doors: Latches do not require more than 15 lbf (67 N) to release the latch. Locks do not require use of a key, tool, or special knowledge for operation. G. Accessibility Requirements: For door hardware on doors in an accessible route, comply with the U.S. Architectural & Transportation Barriers Compliance Board's ADA-ABA Accessibility Guidelines ICC/ANSI A117.1. 1. Provide operating devices that do not require tight grasping, pinching, or twisting of the wrist and that operate with a force of not more than 5 lbf (22.2 N). 2. Comply with the following maximum opening-force requirements: a. Interior, Non-Fire-Rated Hinged Doors: 5 lbf (22.2 N) applied perpendicular to door. b. Sliding or Folding Doors: 5 lbf (22.2 N) applied parallel to door at latch. c. Fire Doors: Minimum opening force allowable by authorities having jurisdiction. 3. Bevel raised thresholds with a slope of not more than 1:2. Provide thresholds not more than 1/2 inch (13 mm) high. 4. Adjust door closer sweep periods so that, from an open position of 70 degrees, the door will take at least 3 seconds to move to a point 3 inches (75 mm) from the latch, measured to the leading edge of the door. H. Keying Conference: Conduct conference to comply with requirements in Section 013113 "Project Coordination." In addition to Owner, Construction Manager, Contractor, and Architect, conference participants shall also include Owner's security consultant. Incorporate keying conference decisions into final keying schedule after reviewing door hardware keying system including, but not limited to, the following: 1. Function of building, flow of traffic, purpose of each area, degree of security required, and plans for future expansion. 2. Preliminary key system schematic diagram. 3. Requirements for key control system. 4. Requirements for access control. 5. Address for delivery of keys. I. Preinstallation Conference: Conduct conference at Project site. 1. Review and finalize construction schedule and verify availability of materials, Installer's personnel, equipment, and facilities needed to make progress and avoid delays. 2. Inspect and discuss preparatory work performed by other trades. 3. Inspect and discuss electrical roughing-in for electrified door hardware. 4. Review sequence of operation for each type of electrified door hardware. DOOR HARDWARE 087100R - 3 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 1.7 H+B Project No. 13-422 July 24, 2014 DELIVERY, STORAGE, AND HANDLING A. Inventory door hardware on receipt and provide secure lock-up for door hardware delivered to Project site. B. Tag each item or package separately with identification coordinated with the final door hardware schedule, and include installation instructions, templates, and necessary fasteners with each item or package. C. Deliver keys and permanent cores to Owner by registered mail or overnight package service. 1.8 COORDINATION A. Coordinate layout and installation of floor-recessed door hardware with floor construction. Cast anchoring inserts into concrete. B. Installation Templates: Distribute for doors, frames, and other work specified to be factory prepared. Check Shop Drawings of other work to confirm that adequate provisions are made for locating and installing door hardware to comply with indicated requirements. C. Security: Coordinate installation of door hardware, keying, and access control with Owner's security consultant. 1.9 WARRANTY A. Special Warranty: Manufacturer's standard form in which manufacturer agrees to repair or replace components of door hardware thatfail in materials or workmanship within specified warranty period. 1. Failures include, but are not limited to, the following: a. Faulty operation of doors and door hardware. b. Deterioration of metals, metal finishes, and other materials beyond normal weathering and use. B. Warranty Period: One year from date of Project Opening, unless otherwise indicated. 1. Mortise Locks: Three years from date of Project Opening. 2. Exit Devices: Three years from date of Project Opening. 3. Manual Closers: Ten years from date of Project Opening. PART 2 - PRODUCTS 2.1 SCHEDULED DOOR HARDWARE A. Provide door hardware for each door as scheduled in Part 3 "Door Hardware Schedule" Article to comply with requirements in this Section. 1. 2. Door Hardware Sets: Provide quantity, item, size, finish or color indicated, and named manufacturers' products. Sequence of Operation: Provide electrified door hardware function, sequence of operation, and interface with other building control systems indicated. DOOR HARDWARE 087100R - 4 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 B. Designations: Requirements for design, grade, function, finish, size, and other distinctive qualities of each type of door hardware are indicated in Part 3 "Door Hardware Schedule" Article. Products are identified by using door hardware designations, as follows: 1. 2.2 H+B Project No. 13-422 July 24, 2014 Named Manufacturers' Products: Manufacturer and product designation are listed for each door hardware type required. Manufacturers' names are abbreviated in Part 3 "Door Hardware Schedule" Article. HINGES A. Hinges: BHMA A156.1. Provide template-produced hinges for hinges installed on hollow-metal doors and hollow-metal frames. 1. Basis-of-Design Product: Subject to compliance with requirements, provide product indicated on schedule or comparable product by one of the following: a. b. c. d. e. 2.3 Bommer Industries, Inc. Hager Companies. IVES Hardware; an Allegion company. McKinney Products Company; an ASSA ABLOY Group company. Stanley Commercial Hardware; Div. of The Stanley Works. CENTER-HUNG AND OFFSET PIVOTS A. Center-Hung and Offset Pivots: BHMA A156.4. 1. Basis-of-Design Product: Subject to compliance with requirements, provide product indicated on schedule or comparable product by one of the following: a. b. 2.4 IVES Hardware; an Allegion company. Rixson Specialty Door Controls; an ASSA ABLOY Group company. CONTINUOUS HINGES A. Continuous Hinges: BHMA A156.26; minimum 0.120-inch- (3.0-mm-) thick, hinge leaves with minimum overall width of 4 inches (102 mm); fabricated to full height of door and frame and to template screw locations; with components finished after milling and drilling are complete. B. Continuous, Gear-Type Hinges: Extruded-aluminum, pinless, geared hinge leaves joined by a continuous extruded-aluminum channel cap; with concealed, self-lubricating thrust bearings. 1. Basis-of-Design Product: Subject to compliance with requirements, provide product indicated on schedule or comparable product by one of the following: a. b. c. DOOR HARDWARE IVES Hardware; an Allegion company. Select Products Limited. Pemko; an ASSA ABLOY Group company. 087100R - 5 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 2.5 H+B Project No. 13-422 July 24, 2014 MECHANICAL LOCKS AND LATCHES A. Lock Functions: As indicated in door hardware schedule. B. Lock Throw: Comply with testing requirements for length of bolts required for labeled fire doors, and as follows: 1. 2. 3. Bored Locks: Minimum 1/2-inch (13-mm) latchbolt throw. Mortise Locks: Minimum 3/4-inch (19-mm) latchbolt throw. Deadbolts: Minimum 1-inch (25-mm) bolt throw. C. Lock Backset: 2-3/4 inches (70 mm), unless otherwise indicated. D. Lock Trim: 1. 2. Description: Schlage escutcheon trim with lever return. Levers: Forged. a. 3. 4. E. Escutcheons and Roses: Wrought, Forged or Cast. Dummy Trim: Match lock trim and escutcheons. Strikes: Provide manufacturer's standard strike for each lock bolt or latchbolt complying with requirements indicated for applicable lock or latch and with strike box and curved lip extended to protect frame; finished to match lock or latch. 1. 2. 3. F. Extra-Long-Lip Strikes: For locks used on frames with applied wood casing trim. Aluminum-Frame Strike Box: Manufacturer's special strike box fabricated for aluminum framing. Rabbet Front and Strike: Provide on locksets for rabbeted meeting stiles. Mortise Locks: BHMA A156.13; Operational and Security Grade 1; stamped steel case with steel parts; Series 1000. 1. Basis-of-Design Product: Subject to compliance with requirements, provide product indicated on schedule or comparable product by one of the following: a. b. c. d. G. Schlage 17N. Corbin Russwin Architectural Hardware; an ASSA ABLOY Group company. SARGENT Manufacturing Company; an ASSA ABLOY Group company. Schlage Commercial Lock Division; an Allegion company. Yale Security Inc.; an ASSA ABLOY Group company. Decorative Owner specific design locks/latches. 1. 2. Manufacturers: Rocky Mountain Hardware. Design: As directed by the Tenant or the Tenant’s representative. All Restoration Hardware design specific Rocky Mountain Hardware designs and styles shall be verified and approved prior to submittal and ordering. Subject to compliance with requirements, provide product type as indicated on schedule. DOOR HARDWARE 087100R - 6 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 2.6 H+B Project No. 13-422 July 24, 2014 SURFACE BOLTS A. Surface Bolts: 1. 2. 2.7 Manufacturers: Subject to compliance with requirements, available manufacturers offering products that may be incorporated into the Work include, but are not limited to, the following: Rocky Mountain Hardware as approved by the Tenant or the Tenant’s representative. MANUAL FLUSH BOLTS A. Manual Flush Bolts: BHMA A156.16; minimum 3/4-inch (19-mm) throw; designed for mortising into door edge. 1. Basis-of-Design Product: Subject to compliance with requirements, provide product indicated on schedule or comparable product by one of the following: a. 2.8 Any member of B.H.M.A. EXIT DEVICES AND AUXILIARY ITEMS A. Exit Devices and Auxiliary Items: BHMA A156.3. 1. Manufacturers: Subject to compliance with requirements, provide products by one of the following: a. 2.9 Von Duprin; an Allegion company. LOCK CYLINDERS A. Lock Cylinders: Tumbler type, constructed from brass or bronze, stainless steel, or nickel silver in small format interchangeable core (SFIC) configuration. 1. Manufacturers: following: a. B. 2.10 A. Best Access Systems; Div. of Stanley Security Solutions, Inc. Construction Cores: Provide construction cores that are replaceable by permanent cores. Provide 10 construction master keys. KEYING Keying System: Factory registered, complying with guidelines in BHMA A156.28, Appendix A. Incorporate decisions made in keying conference. 1. B. Subject to compliance with requirements, provide products by the Great-Grand Master Key System: Change keys, a master key, a grand master key, and a great-grand master key operate cylinders. Keys: Nickel silver or Brass. DOOR HARDWARE 087100R - 7 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 1. Stamping: Permanently inscribe each key with a visual key control number and include the following notation: a. 2. A. Cylinder Change Keys: Three. Master Keys: Five. Grand Master Keys: Five. Great-Grand Master Keys: Five. OPERATING TRIM Operating Trim: BHMA A156.6; brass, bronze or stainless steel, unless otherwise indicated. 1. Basis-of-Design Product: Subject to compliance with requirements, provide product indicated on schedule or comparable product by one of the following: a. 2.12 Notation: "DO NOT DUPLICATE." and/or Information furnished by Owner. Quantity: In addition to one extra key blank for each lock, provide the following: a. b. c. d. 2.11 H+B Project No. 13-422 July 24, 2014 Any member of B.H.M.A. ACCESSORIES FOR PAIRS OF DOORS A. Coordinators: BHMA A156.3; consisting of active-leaf, hold-open lever and inactive-leaf release trigger; fabricated from steel with nylon-coated strike plates; with built-in, adjustable safety release and with internal override. B. Astragals: BHMA A156.22. 2.13 A. SURFACE CLOSERS Surface Closers: BHMA A156.4; rack-and-pinion hydraulic type with adjustable sweep and latch speeds controlled by key-operated valves and forged-steel main arm. Comply with manufacturer's written recommendations for size of door closers depending on size of door, exposure to weather, and anticipated frequency of use. Provide factory-sized closers, adjustable to meet field conditions and requirements for opening force. 1. Manufacturers: Subject to compliance with requirements, provide products by one of the following: a. 2.14 A. LCN Closers; an Allegion company. MECHANICAL STOPS AND HOLDERS Wall- and Floor-Mounted Stops: BHMA A156.16; brass, bronze, or stainless steel base metal. 1. Basis-of-Design Product: Subject to compliance with requirements, provide product indicated on schedule or comparable product by one of the following: DOOR HARDWARE 087100R - 8 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 a. 2.15 A. Overhead Stops and Holders: BHMA A156.8. Basis-of-Design Product: Subject to compliance with requirements, provide product indicated on schedule or comparable product by one of the following: a. b. c. A. Door Gasketing: BHMA A156.22; air leakage not to exceed 0.50 cfm per foot (0.000774 cu. m/s per m) of crack length for gasketing other than for smoke control, as tested according to ASTM E 283; with resilient or flexible seal strips that are easily replaceable and readily available from stocks maintained by manufacturer. Basis-of-Design Product: Subject to compliance with requirements, provide product indicated on schedule or comparable product by one of the following: a. b. c. A. Thresholds: BHMA A156.21; fabricated to full width of opening indicated. Basis-of-Design Product: Subject to compliance with requirements, provide product indicated on schedule or comparable product by one of the following: a. b. c. d. e. A. National Guard Products. Pemko Manufacturing Co.; an ASSA ABLOY Group company. Reese Enterprises, Inc. THRESHOLDS 1. 2.18 Architectural Builders Hardware Mfg., Inc. Glynn-Johnson; an Allegion company. Rixson; an ASSA ABLOY Group company. DOOR GASKETING 1. 2.17 Any member of B.H.M.A. OVERHEAD STOPS AND HOLDERS 1. 2.16 H+B Project No. 13-422 July 24, 2014 National Guard Products. Pemko Manufacturing Co.; an ASSA ABLOY Group company. Reese Enterprises, Inc. Wooster Products Company. Safe-T-Metal Company. METAL PROTECTIVE TRIM UNITS Metal Protective Trim Units: BHMA A156.6; fabricated from 0.050-inch- (1.3-mm-) thick stainless steel; with manufacturer's standard machine or self-tapping screw fasteners. 1. Manufacturers: Subject to compliance with requirements, available manufacturers offering products that may be incorporated into the Work include, but are not limited to, the following: DOOR HARDWARE 087100R - 9 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 a. 2.19 A. Any member of B.H.M.A. AUXILIARY DOOR HARDWARE Auxiliary Hardware: BHMA A156.16. 1. Manufacturers: Subject to compliance with requirements, available manufacturers offering products that may be incorporated into the Work include, but are not limited to, the following: a. 2.20 H+B Project No. 13-422 July 24, 2014 Any member of B.H.M.A. FABRICATION A. Base Metals: Produce door hardware units of base metal indicated, fabricated by forming method indicated, using manufacturer's standard metal alloy, composition, temper, and hardness. Furnish metals of a quality equal to or greater than that of specified door hardware units and BHMA A156.18. B. Fasteners: Provide door hardware manufactured to comply with published templates prepared for machine, wood, and sheet metal screws. Provide screws that comply with commercially recognized industry standards for application intended, except aluminum fasteners are not permitted. Provide Phillips flat-head screws with finished heads to match surface of door hardware, unless otherwise indicated. 1. 2. Concealed Fasteners: For door hardware units that are exposed when door is closed, except for units already specified with concealed fasteners. Do not use through bolts for installation where bolt head or nut on opposite face is exposed unless it is the only means of securely attaching the door hardware. Where through bolts are used on hollow door and frame construction, provide sleeves for each through bolt. Fire-Rated Applications: a. Wood or Machine Screws: For the following: 1) 2) 3) b. Steel Through Bolts: For the following unless door blocking is provided: 1) 2) 3) 3. 4. 5. Hinges mortised to doors or frames; use threaded-to-the-head wood screws for wood doors and frames. Strike plates to frames. Closers to doors and frames. Surface hinges to doors. Closers to doors and frames. Surface-mounted exit devices. Spacers or Sex Bolts: For through bolting of hollow-metal doors. Fasteners for Wood Doors: Comply with requirements in DHI WDHS.2, "Recommended Fasteners for Wood Doors." Gasketing Fasteners: Provide noncorrosive fasteners for exterior applications and elsewhere as indicated. DOOR HARDWARE 087100R - 10 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 2.21 H+B Project No. 13-422 July 24, 2014 FINISHES A. Provide finishes complying with BHMA A156.18 as indicated in door hardware schedule. B. Protect mechanical finishes on exposed surfaces from damage by applying a strippable, temporary protective covering before shipping. C. Appearance of Finished Work: Variations in appearance of abutting or adjacent pieces are acceptable if they are within one-half of the range of approved Samples. Noticeable variations in the same piece are not acceptable. Variations in appearance of other components are acceptable if they are within the range of approved Samples and are assembled or installed to minimize contrast. PART 3 - EXECUTION 3.1 EXAMINATION A. Examine doors and frames, with Installer present, for compliance with requirements for installation tolerances, labeled fire-rated door assembly construction, wall and floor construction, and other conditions affecting performance. B. Examine roughing-in for electrical power systems to verify actual locations of wiring connections before electrified door hardware installation. C. Proceed with installation only after unsatisfactory conditions have been corrected. 3.2 PREPARATION A. Steel Doors and Frames: For surface applied door hardware, drill and tap doors and frames according to ANSI/SDI A250.6. B. Wood Doors: Comply with DHI WDHS.5 "Recommended Hardware Reinforcement Locations for Mineral Core Wood Flush Doors." 3.3 INSTALLATION A. Mounting Heights: Mount door hardware units at heights to comply with the following unless otherwise indicated or required to comply with governing regulations. 1. 2. 3. B. Standard Steel Doors and Frames: ANSI/SDI A250.8. Custom Steel Doors and Frames: HMMA 831. Wood Doors: DHI WDHS.3, "Recommended Locations for Architectural Hardware for Wood Flush Doors." Install each door hardware item to comply with manufacturer's written instructions. Where cutting and fitting are required to install door hardware onto or into surfaces that are later to be painted or finished in another way, coordinate removal, storage, and reinstallation of surface protective trim units with finishing. Do not install surface-mounted items until finishes have been completed on substrates involved. DOOR HARDWARE 087100R - 11 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 1. 2. H+B Project No. 13-422 July 24, 2014 Set units level, plumb, and true to line and location. Adjust and reinforce attachment substrates as necessary for proper installation and operation. Drill and countersink units that are not factory prepared for anchorage fasteners. Space fasteners and anchors according to industry standards. C. Hinges: Install types and in quantities indicated in door hardware schedule but not fewer than the number recommended by manufacturer for application indicated or one hinge for every 30 inches (750 mm) of door height, whichever is more stringent, unless other equivalent means of support for door, such as spring hinges or pivots, are provided. D. Intermediate Offset Pivots: Where offset pivots are indicated, provide intermediate offset pivots in quantities indicated in door hardware schedule but not fewer than one intermediate offset pivot per door and one additional intermediate offset pivot for every 30 inches (750 mm) of door height greater than 90 inches (2286 mm). E. Lock Cylinders: Install construction cores to secure building and areas during construction period. 1. Replace construction cores with permanent cores as indicated in keying schedule and as directed by Owner. F. Thresholds: Set thresholds for exterior doors and other doors indicated in full bed of sealant complying with requirements specified in Section 079200 "Joint Sealants." G. Perimeter Gasketing: Apply to head and jamb, forming seal between door and frame. H. Meeting Stile Gasketing: Fasten to meeting stiles, forming seal when doors are closed. I. Door Bottoms: Apply to bottom of door, forming seal with threshold when door is closed. 3.4 ADJUSTING A. Initial Adjustment: Adjust and check each operating item of door hardware and each door to ensure proper operation or function of every unit. Replace units that cannot be adjusted to operate as intended. Adjust door control devices to compensate for final operation of heating and ventilating equipment and to comply with referenced accessibility requirements. 1. B. 3.5 Door Closers: Adjust sweep period to comply with accessibility requirements and requirements of authorities having jurisdiction Occupancy Adjustment: Approximately three months after date of Substantial Completion, Installer's shall examine and readjust each item of door hardware, including adjusting operating forces, as necessary to ensure function of doors, and door hardware. CLEANING AND PROTECTION A. Clean adjacent surfaces soiled by door hardware installation. B. Clean operating items as necessary to restore proper function and finish. C. Provide final protection and maintain conditions that ensure that door hardware is without damage or deterioration at time of Substantial Completion. DOOR HARDWARE 087100R - 12 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 3.6 DEMONSTRATION A. 3.7 H+B Project No. 13-422 July 24, 2014 Engage a factory-authorized service representative to train Owner's maintenance personnel to adjust, operate, and maintain door hardware and door hardware finishes. Refer to Section 017900 "Demonstration and Training." DOOR HARDWARE SCHEDULE HARDWARE SET NO. 01 EACH TO HAVE: 1 EA CONT. HINGE 1 EA FIRE EXIT HARDWARE 1 EA SURFACE CLOSER 1 EA KICK PLATE 1 SET WEATHER SEAL 1 EA DOOR SWEEP 1 EA THRESHOLD 224HD 98-EO-F 4111 SCUSH MC 8400 10" X 2" LDW B4E 5050B 600 425HD 710 313 US10B 613 BRN DKB DKB IVE VON LCN IVE NGP NGP NGP 5BB1HW 4.5 X 4.5 NRP 98-L-BE-F-996-03 4011 MC 8400 10" X 2" LDW B4E WS447 640 313 US10B 613 613 IVE VON LCN IVE IVE 5BB1HW 4.5 X 4.5 NRP MB12 L304 4040XP H MC 8400 10" X 1" LDW B4E 115N 600 813 613 613 DKB US10B 613 DKB DKB DKB IVE RKY RKY LCN IVE NGP NGP NGP MB12 L304 613 DKB RKY RKY HARDWARE SET NO. 02 EACH TO HAVE: 3 EA HW HINGE 1 EA FIRE EXIT HARDWARE 1 EA SURFACE CLOSER 1 EA KICK PLATE 1 EA WALL STOP HARDWARE SET NO. 03 EACH TO HAVE: 8 EA HW HINGE 2 EA SURFACE BOLT 1 EA LATCHSET TRIM 2 EA SURFACE CLOSER 2 EA KICK PLATE 1 SET ASTRAGAL 2 EA DOOR SWEEP 1 EA THRESHOLD HARDWARE SET NO. 03.1 EACH TO HAVE: 2 EA SURFACE BOLT 1 EA (DUMMY) TRIM DOOR HARDWARE 087100R - 13 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 DOOR/WINDOW PANELS ARE INOPERABLE. HARDWARE ITEMS ARE NON-FUNCTIONING AND ARE FOR APPEARANCE ONLY. HARDWARE SET NO. 03.2 (ADDED FOR DOORS A112.1, A112.2, A112.3 & A112.4) EACH TO HAVE: 8 EA HW HINGE 1 EA REMOVABLE MULLION 2 EA DOOR PULL TRIM 1 EA PANIC HARDWARE 1 EA PANIC HARDWARE 1 EA SFIC RIM CYLINDER 2 EA SURFACE CLOSER 2 EA KICK PLATE 1 SET ASTRAGAL 2 EA DOOR SWEEP 1 EA THRESHOLD 5BB1HW 4.5 X 4.5 NRP 5654 G263 55-EO 55-NL-OP-110MD 80-116 4040XP H MC 8400 10" X 1" LDW B4E 115N 600 813 613 313 DKB 613 613 613 US10B 613 DKB DKB DKB IVE VON RKY VON VON SCH LCN IVE NGP NGP NGP THE EXIT DEVICES MAY BE DOGGED (LATCHBOLT HELD RETRACTED) FOR PUSH/PULL OPERATION. HARDWARE SET NO. 03.3 (ADDED FOR DOORS A303.1 & A304.1) EACH TO HAVE: 8 EA HW HINGE 2 EA SURFACE BOLT 1 EA LOCK TRIM 1 EA SFIC MORTISE CYL. 2 EA SURFACE CLOSER 2 EA KICK PLATE 1 SET ASTRAGAL 2 EA DOOR SWEEP 1 EA THRESHOLD 5BB1HW 4.5 X 4.5 NRP MB12 L304 (CLASSROOM) 80-110 4040XP H MC 8400 10" X 1" LDW B4E 115N 600 813 613 613 DKB 613 US10B 613 DKB DKB DKB IVE RKY RKY SCH LCN IVE NGP NGP NGP LATCHBOLT RETRACTED BY LEVER FROM EITHER SIDE UNLESS RETAIL SIDE LEVER IS LOCKED BY KEY. RETAIL SIDE LEVER IS UNLOCKED BY KEY FROM RETAIL SIDE ONLY. BRIDGE SIDE LEVER IS ALWAYS FREE FOR IMMEDIATE EGRESS 24/7/365. HARDWARE SET NO. 04 EACH TO HAVE: 10 EA HW HINGE 2 EA SURFACE BOLT 1 EA LATCHSET TRIM 2 EA SURFACE CLOSER 2 EA KICK PLATE 1 SET ASTRAGAL 2 EA DOOR SWEEP 1 EA THRESHOLD DOOR HARDWARE 5BB1HW 5 X 4.5 NRP MB12 L304 4040XP H MC 8400 10" X 1" LDW B4E 115N 600 813 613 613 DKB US10B 613 DKB DKB DKB IVE RKY RKY LCN IVE NGP NGP NGP 087100R - 14 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 HARDWARE SET NO. 05 EACH TO HAVE: 10 EA HW HINGE 2 EA DOOR PULL TRIM 2 EA PANIC HARDWARE 2 EA PANIC HARDWARE 2 EA SURFACE CLOSER 2 EA KICK PLATE 2 EA KICK PLATE 2 EA DOOR SWEEP 2 EA THRESHOLD 5BB1HW 5 X 4.5 NRP G263 55-EO 5547-EO 4040XP H MC 8400 10" X 1" LDW B4E 8400 10” X 2” LDW B4E 600 813 613 DKB 613 626 US10B 613 613 DKB DKB IVE RKY VON VON LCN IVE IVE NGP NGP 224HD LV9080BDC 03N 4111 SHCUSH MC 5050B 600 425HD 710 613 US10B BRN DKB DKB IVE SCH LCN NGP NGP NGP 5BB1HW 4.5 X 4.5 NRP MB12 L304 4040XP H MC 8400 10" X 1" LDW B4E 115N 600 813 613 613 DKB US10B 613 DKB DKB DKB IVE RKY RKY LCN IVE NGP NGP NGP MB12 L304 613 DKB RKY RKY HARDWARE SET NO. 06 EACH TO HAVE: 1 EA CONT. HINGE 1 EA STOREROOM LOCK 1 EA SURFACE CLOSER 1 SET WEATHER SEAL 1 EA DOOR SWEEP 1 EA THRESHOLD HARDWARE SET NO. 07 EACH TO HAVE: 6 EA HW HINGE 2 EA SURFACE BOLT 1 EA LATCHSET TRIM 2 EA SURFACE CLOSER 2 EA KICK PLATE 1 SET ASTRAGAL 2 EA DOOR SWEEP 1 EA THRESHOLD HARDWARE SET NO. 07.1 EACH TO HAVE: 2 EA SURFACE BOLT 1 EA (DUMMY) TRIM DOOR/WINDOW PANELS ARE INOPERABLE. HARDWARE ITEMS ARE NON-FUNCTIONING AND ARE FOR APPEARANCE ONLY. DOOR HARDWARE 087100R - 15 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 HARDWARE SET NO. 08 EACH TO HAVE: 1 EA CONT. HINGE 1 EA FIRE EXIT HARDWARE 1 EA SURFACE CLOSER 1 EA WALL STOP 1 SET WEATHER SEAL 1 EA DOOR SWEEP 1 EA THRESHOLD 224HD 98-EO-F-WH PBAR 4011 MC WS447 5050B 600 425HD 710 313 US10B 613 BRN DKB DKB IVE VON LCN IVE NGP NGP NGP 5BB1HW 4.5 X 4.5 NRP LV9080BDC 03N 4040XP CUSH MC 613 613 US10B IVE SCH LCN 224HD SB453 8" TB LV9080BDC 03N 90H 5050B 115N 600 425HD 710 640 613 613 BRN DKB DKB DKB IVE IVE SCH GLY NGP NGP NGP NGP 5BB1HW 4.5 X 4.5 NRP MB12 L304 4040XP H MC 600 813 613 613 DKB US10B DKB DKB IVE RKY RKY LCN NGP NGP 224HD 710 IVE HARDWARE SET NO. 09 EACH TO HAVE: 3 EA HW HINGE 1 EA STOREROOM LOCK 1 EA SURFACE CLOSER HARDWARE SET NO. 10 EACH TO HAVE: 2 EA CONT. HINGE 2 EA SURFACE BOLT 1 EA STOREROOM LOCK 2 EA OH STOP & HOLDER 1 SET WEATHER SEAL 1 SET ASTRAGAL 2 EA DOOR SWEEP 1 EA THRESHOLD HARDWARE SET NO. 11 EACH TO HAVE: 6 2 1 2 2 1 EA EA EA EA EA EA HW HINGE SURFACE BOLT LATCHSET TRIM SURFACE CLOSER DOOR SWEEP THRESHOLD HARDWARE SET NO. 12 EACH TO HAVE: 1 EA CONT. HINGE DOOR HARDWARE 087100R - 16 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 1 EA STOREROOM LOCK LV9080L LLL 03N L283-150 H+B Project No. 13-422 July 24, 2014 613 SCH END OF SECTION 087100R DOOR HARDWARE 087100R - 17 THIS PAGE INTENTIONALLY LEFT BLANK CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 SECTION 099113 - EXTERIOR PAINTING PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Division 00 - Procurement and Contracting Requirements, and Division 01 - General Requirements, are hereby made part of this Section. SUMMARY A. 1.3 Section includes surface preparation and the application of paint systems on exterior substrates as shown on drawings and in schedules.. ACTION SUBMITTALS A. Product Data: instructions. B. Samples for Initial Selection: For each type of topcoat product. C. Samples for Verification: For each type of paint system and each color and gloss of topcoat. 1. 2. 3. 4. D. Include preparation requirements and application Submit Samples on rigid backing, 8 inches (200 mm) square. Step coats on Samples to show each coat required for system. Label each coat of each Sample. Label each Sample for location and application area. Product List: For each product indicated, include the following: 1. 2. 3. 1.4 For each type of product. Cross-reference to paint system and locations of application areas. Use same designations indicated on Drawings and in schedules. Printout of current "MPI Approved Products List" for each product category specified, with the proposed product highlighted. VOC content. MAINTENANCE MATERIAL SUBMITTALS A. Furnish extra materials that match products installed and that are packaged with protective covering for storage and identified with labels describing contents. 1. 1.5 Paint: 5 percent, but not less than 1 gal. (3.8 L) of each material and color applied. QUALITY ASSURANCE A. Mockups: Apply mockups of each paint system indicated and each color and finish selected to verify preliminary selections made under Sample submittals and to demonstrate aesthetic effects and set quality standards for materials and execution. EXTERIOR PAINTING 099113R - 1 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 1. Architect will select one surface to represent surfaces and conditions for application of each paint system specified in Part 3. a. b. Vertical and Horizontal Surfaces: Provide samples of at least 100 sq. ft. (9 sq. m). Other Items: Architect will designate items or areas required. 2. Final approval of color selections will be based on mockups. 3. Approval of mockups does not constitute approval of deviations from the Contract Documents contained in mockups unless Architect specifically approves such deviations in writing. Subject to compliance with requirements, approved mockups may become part of the completed Work if undisturbed at time of Substantial Completion. 4. 1.6 H+B Project No. 13-422 July 24, 2014 DELIVERY, STORAGE, AND HANDLING A. Store materials not in use in tightly covered containers in well-ventilated areas with ambient temperatures continuously maintained at not less than 45 deg F (7 deg C). 1. 2. 1.7 Maintain containers in clean condition, free of foreign materials and residue. Remove rags and waste from storage areas daily. FIELD CONDITIONS A. Apply paints only when temperature of surfaces to be painted and ambient air temperatures are between 50 and 95 deg F (10 and 35 deg C). B. Do not apply paints when relative humidity exceeds 85 percent; or to damp or wet surfaces. PART 2 - PRODUCTS 2.1 MANUFACTURERS A. Manufacturers: Subject to compliance with requirements, provide products by the following: 1. 2. 3. 4. 5. 2.2 Benjamin Moore & Co. ICI Paints. PPG Architectural Finishes, Inc. Sherwin-Williams Company (The). Tnemec Company, Inc. PAINT, GENERAL A. MPI Standards: Provide products that comply with MPI standards indicated and that are listed in its "MPI Approved Products List." B. Material Compatibility: 1. Provide materials for use within each paint system that are compatible with one another and substrates indicated, under conditions of service and application as demonstrated by manufacturer, based on testing and field experience. EXTERIOR PAINTING 099113R - 2 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 2. C. H+B Project No. 13-422 July 24, 2014 For each coat in a paint system, provide products recommended in writing by manufacturers of topcoat for use in paint system and on substrate indicated. Colors: Refer to Material Legend. PART 3 - EXECUTION 3.1 EXAMINATION A. Examine substrates and conditions, with Applicator present, for compliance with requirements for maximum moisture content and other conditions affecting performance of the Work. B. Maximum Moisture Content of Substrates: When measured with an electronic moisture meter as follows: 1. 2. Concrete: 12 percent. Masonry (Clay and CMU): 12 percent. C. Verify suitability of substrates, including surface conditions and compatibility with existing finishes and primers. D. Proceed with coating application only after unsatisfactory conditions have been corrected. 1. 3.2 Application of coating indicates acceptance of surfaces and conditions. PREPARATION A. Comply with manufacturer's written instructions and recommendations in "MPI Manual" applicable to substrates and paint systems indicated. B. Remove hardware, covers, plates, and similar items already in place that are removable and are not to be painted. If removal is impractical or impossible because of size or weight of item, provide surface-applied protection before surface preparation and painting. 1. C. After completing painting operations, use workers skilled in the trades involved to reinstall items that were removed. Remove surface-applied protection. Clean substrates of substances that could impair bond of paints, including dust, dirt, oil, grease, and incompatible paints and encapsulants. 1. Remove incompatible primers and reprime substrate with compatible primers or apply tie coat as required to produce paint systems indicated. D. Concrete Substrates: Remove release agents, curing compounds, efflorescence, and chalk. Do not paint surfaces if moisture content or alkalinity of surfaces to be painted exceeds that permitted in manufacturer's written instructions. E. Masonry Substrates: Remove efflorescence and chalk. Do not paint surfaces if moisture content or alkalinity of surfaces or mortar joints exceeds that permitted in manufacturer's written instructions. EXTERIOR PAINTING 099113R - 3 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 F. Shop-Primed Steel Substrates: Clean field welds, bolted connections, and abraded areas of shop paint, and paint exposed areas with the same material as used for shop priming to comply with SSPC-PA 1 for touching up shop-primed surfaces. G. Galvanized-Metal Substrates: Remove grease and oil residue from galvanized sheet metal by mechanical methods to produce clean, lightly etched surfaces that promote adhesion of subsequently applied paints. 3.3 APPLICATION A. Apply paints according to manufacturer's written instructions and recommendations in "MPI Manual." 1. 2. 3. 4. 5. Use applicators and techniques suited for paint and substrate indicated. Paint surfaces behind movable items same as similar exposed surfaces. Before final installation, paint surfaces behind permanently fixed items with prime coat only. Paint both sides and edges of exterior doors and entire exposed surface of exterior door frames. Do not paint over labels of independent testing agencies or equipment name, identification, performance rating, or nomenclature plates. Primers specified in painting schedules may be omitted on items that are factory primed or factory finished if acceptable to topcoat manufacturers. B. Tint undercoats same color as topcoat, but tint each undercoat a lighter shade to facilitate identification of each coat if multiple coats of same material are to be applied. Provide sufficient difference in shade of undercoats to distinguish each separate coat. C. If undercoats or other conditions show through topcoat, apply additional coats until cured film has a uniform paint finish, color, and appearance. D. Apply paints to produce surface films without cloudiness, spotting, holidays, laps, brush marks, roller tracking, runs, sags, ropiness, or other surface imperfections. Cut in sharp lines and color breaks. E. Painting Fire Suppression, Plumbing, HVAC, Electrical, Communication, and Electronic Safety and Security Work: 1. Paint the following work where exposed to view: a. b. c. d. e. f. 3.4 Equipment, including panelboards. Uninsulated metal piping. Uninsulated plastic piping. Pipe hangers and supports. Metal conduit. Plastic conduit. FIELD QUALITY CONTROL A. Dry Film Thickness Testing: Owner may engage the services of a qualified testing and inspecting agency to inspect and test paint for dry film thickness. 1. 2. Contractor shall touch up and restore painted surfaces damaged by testing. If test results show that dry film thickness of applied paint does not comply with paint manufacturer's written recommendations, Contractor shall pay for testing and apply EXTERIOR PAINTING 099113R - 4 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 H+B Project No. 13-422 July 24, 2014 additional coats as needed to provide dry film thickness that complies with paint manufacturer's written recommendations. 3.5 CLEANING AND PROTECTION A. At end of each workday, remove rubbish, empty cans, rags, and other discarded materials from Project site. B. After completing paint application, clean spattered surfaces. Remove spattered paints by washing, scraping, or other methods. Do not scratch or damage adjacent finished surfaces. C. Protect work of other trades against damage from paint application. Correct damage to work of other trades by cleaning, repairing, replacing, and refinishing, as approved by Architect, and leave in an undamaged condition. D. At completion of construction activities of other trades, touch up and restore damaged or defaced painted surfaces. 3.6 EXTERIOR PAINTING SCHEDULE A. CMU Substrates: MPI EXT 4.2A 1. Latex System: a. b. c. B. Galvanized-Metal Substrates: 1. 2. C. Alkyd System: MPE EXT 5.3B. a. Prime Coat: Cementitious galvanized-metal primer. b. Intermediate Coat: Exterior alkyd enamel matching topcoat. Topcoat: Exterior alkyd enamel (flat). Steel Substrates, where noted on drawings: 1. Water-Based Light Industrial Coating System: a. b. c. D. Prime Coat: Block filler, latex, interior/exterior. Intermediate Coat: Latex, exterior, matching topcoat. Topcoat: Latex, exterior, Gloss Level and color as noted in Material Finish Legend. Prime Coat: Primer, alkyd, anti-corrosive for metal, MPI #79. Intermediate Coat: Light industrial coating, exterior, water based, matching topcoat. Topcoat: Light industrial coating, exterior, water based, semi-gloss (Gloss Level and color as noted in material Finish Legend. Exterior Steel exposed to view (for AESS steel as noted on drawings). 1. 2. For warranty purposes, the Contractor shall insure that the specified primer in Division 5 “Architecturally Exposed Structural Steel Framing” and the intermediate and finish coats specified below are from the same manufacturer. Intermediate Coat: a. 3. Tnemec: One (1) coat TNEMEC Series 161 TNEMEC - Fascure @ 4.0 to 6.0 mils DFT. Finish Coat: EXTERIOR PAINTING 099113R - 5 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 a. b. 3.7 H+B Project No. 13-422 July 24, 2014 Tnemec: One (1) coat TNEMEC Series 1075U Endura-Shield @ 2.0 to 5.0 mil DFT. Color as noted in material Finish Legend. ELECTRICAL, COMMUNICATIONS, AND SAFETY & SECURITY A. Exterior Exposed Electrical Conduit Fittings, Boxes, and other miscellaneous exterior electrical items. 1. First Coat – Galvanized Metal: a. b. c. d. 2. First Coat - Ferrous Metal: a. b. c. d. 3. Benjamin Moore: M04 Acrylic Metal Primer. ICI Paints: Devoe Coatings DevFlex 4020PF Direct to Metal Primer & Flat Finish. Pittsburgh Paints: 90-708 Series, Pitt-Tech One Pack Interior/Exterior Industrial Primer. Sherwin Williams: DTM Acrylic Primer/Finish, B66W1. Second and Third Coats: a. b. c. d. 3.8 Benjamin Moore: M04 Acrylic Metal Primer. ICI Paints: Devoe Coatings DevFlex 4020PF Direct to Metal Primer & Flat Finish. Pittsburgh Paints: 90-708 Series, Pitt-Tech One Pack Interior/Exterior Industrial Primer. Sherwin Williams: DTM Acrylic Primer/Finish, B66W1. Benjamin Moore: Impervex Enamel 309. ICI Paints: Devoe Coatings Tru-Glaze 4418 Waterborne Acrylic Epoxy Coating. Pittsburgh Paints: 90-374 Series, Pitt-Tech One Pack Interior/Exterior Gloss High Performance Industrial Enamel. Sherwin Williams: DTM Acrylic Gloss Coating (Water Reducible), B66 Series. MECHANICAL, PLUMBING AND FIRE SUPPRESSION A. Apparatus, Equipment, and Equipment Supports. 1. First Coat: a. b. c. d. 2. Benjamin Moore: M04 Acrylic Metal Primer. ICI Paints: Devoe Coatings DevFlex 4020PF Direct to Metal Primer & Flat Finish. Pittsburgh Paints: 90-708 Series, Pitt-Tech One Pack Interior/ Exterior. Sherwin Williams: DTM Acrylic Primer/Finish B66W1. Second Coat: a. b. c. EXTERIOR PAINTING Benjamin Moore: Moorcraft Latex Semi Gloss Enamel 276. ICI Paints: Devoe Coatings DevFlex 4216HP High Performance Waterborne Acrylic Semi-Gloss Enamel. Pittsburgh Paints: 90-474 Series, Pitt-Tech One Pack Interior/Exterior Satin High Performance Industrial Enamel. 099113R - 6 CHERRY CREEK SHOPPING CENTER – RH Bulletin No. 3 d. B. Sherwin Williams: Metalatex Semi Gloss Enamel, B42 Series. Exposed Bare Piping, Valves, Fittings, and Hangers: 1. First Coat: a. Benjamin Moore: M04 Acrylic Metal Primer. b. ICI Paints: Devoe Coatings DevFlex 4020PF Direct to Metal Primer & Flat Finish. c. Pittsburgh Paints: 90-708 Series, Pitt-Tech One Pack Interior/Exterior Industrial Primer. d. Sherwin Williams: DTM Acrylic Primer/Finish, B66W1 at all metals except copper. At copper, use Ken Kromik Metal Primer, B50 Series. 2. Second Coat: a. b. c. d. C. H+B Project No. 13-422 July 24, 2014 Benjamin Moore: Moorcraft Latex Semi Gloss 276. ICI Paints: Devoe Coatings DevFlex 4216HP High Performance Waterborne Acrylic Semi-Gloss Enamel. Pittsburgh Paints: 90-474 Series, Pitt-Tech One Pack Interior/Exterior Satin High Performance Industrial Enamel. Sherwin Williams: Metalatex Semi Gloss Enamel, B42 Series. Exterior Ductwork Exposed to Weather 1. First Coat (Heavy coat of one of the following): a. b. c. d. 2. Glidden: 61778 Glid-Guard Top Service Thick Black. ICI Paints: Devoe Coatings Bar-Rust 235 Multi-Purpose Epoxy Coating. Pittsburgh Paints: 95-240 Series, Pitt-Guard Rapid Coat D-T-R. Sherwin Williams: Macropoxy 646 Fast Cure, B58-600/B58V600. Second and Third Coats (allow 24 hours drying time after first coat): a. b. c. d. Glidden: 61780 Coat Tar Emulsion. ICI Paints: Devoe Coatings Bar-Rust 235 Multi-Purpose Epoxy Coating. Pittsburgh Paints: 95-240 Series, Pitt-Guard Rapid Coat D-T-R. Sherwin Williams: Hi-Solids Polyurethane B65-300. END OF SECTION 099113R EXTERIOR PAINTING 099113R - 7 THIS PAGE INTENTIONALLY LEFT BLANK

© Copyright 2026