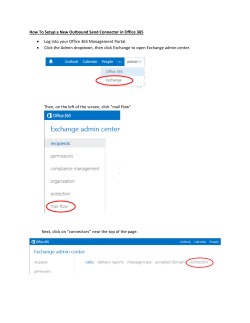

Document 333297