Servitization in the Capital Goods Industry Geert-Jan van Houtum

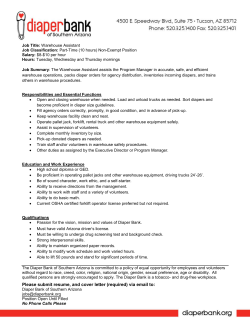

Euroma Service Operations Management Forum, Tilburg, 22 Sept. 2014 Servitization in the Capital Goods Industry Geert-Jan van Houtum Prof. of Maintenance, Reliability, and Quality Eindhoven University of Technology [email protected] / School of Industrial Engineering 10/15/2014 PAGE 1 Key words: System availability Total Cost of Ownership / School of Industrial Engineering 10/15/2014 PAGE 2 Size capital goods industry Netherlands Import: 117 billion Euro Export: 117 billion Euro Source: Statistisch Jaarboek, 2009 Concerns: “Machines en apparaten, Elektrotechnische machines en apparaten, Transportmiddelen” / School of Industrial Engineering 10/15/2014 PAGE 3 Size capital goods industry Netherlands Import: 117 billion Euro Export: 117 billion Euro Potential size services: Equally large !!! Source: Statistisch Jaarboek, 2009 Concerns: “Machines en apparaten, Elektrotechnische machines en apparaten, Transportmiddelen” / School of Industrial Engineering 10/15/2014 PAGE 4 Life Cycle Needs and requirements Design Production Big influence on System Availability and TCO One may look at: • Modular design • More reliable components • Building in redundancy • Means to facilitate monitoring and diagnosis •… / School of Industrial Engineering Exploitation Disposal • The maximum system availability is determined in the design phase • A large portion of the TCO is made in this phase 10/15/2014 PAGE 5 Long term trends • Maintenance of complex systems becomes too complicated for users themselves • Users require higher system availabilities (less downtime) • Users look at TCO • Maintenance is outsourced to third party or OEM (pooling resources, pooling data, remote monitoring) • More extreme: One sells function plus availability • Feedback to design (better systems, higher sustainability) / School of Industrial Engineering 10/15/2014 PAGE 6 Challenges for the OEM\third party? • Definition of the service portfolio / School of Industrial Engineering 10/15/2014 PAGE 7 Example of a service portfolio / School of Industrial Engineering 10/15/2014 PAGE 8 Challenges for the OEM\third party? • Definition of the service portfolio • Design of the service supply chain / School of Industrial Engineering 10/15/2014 PAGE 9 Service supply chain: Example Reg. repl.: 1-2 weeks Local Stockpoint Central Stockpoint Emergency Shipm.: 1-2 days Supply spare parts Direct sales / School of Industrial Engineering Customers with contracts Lateral Shipments: A few hours Customers with contracts Reg. repl.: 1-2 weeks Local Stockpoint 10/15/2014 PAGE 10 Challenges for the OEM\third party? • • • • • • • Definition of the service portfolio Design of the service supply chain Design of the service processes Pricing Organization New business models … / School of Industrial Engineering 10/15/2014 PAGE 11 PURPOSE OF THIS TALK Showing how we can contribute via OM research / School of Industrial Engineering 10/15/2014 PAGE 12 CONTENTS 1. Introduction 2. Creation of differentiation while keeping the portfolio effect 3. Effect of product design: Redundancy decision 4. New opportunity: Remote monitoring data 5. General OM research agenda / School of Industrial Engineering 10/15/2014 PAGE 13 2. Creation of differentiation while keeping the portfolio effect (Tiemessen, Fleischmann, v.Houtum, v.Nunen, and Pratsini, EJOR, 2013) / School of Industrial Engineering 10/15/2014 PAGE 14 Spare parts network for high-tech equipment HUB Legend Local Warehouse 4hr response area 2hr response area customer (region) / School of Industrial Engineering 10/15/2014 PAGE 15 Spare parts network for high-tech equipment Spare parts network Legend HUB Local Warehouse 4hr response area 2hr response area customer (region) Key features: Lateral transshipments Multiple customer classes / School of Industrial Engineering 10/15/2014 PAGE 16 Setting • • • • Central Warehouse (CW): Infinite stock Multiple Local Warehouses (LW’s) Poisson demand processes Cost factors: • Cost to fulfill a demand at point x from LW i or from the CW • Unit replenishment costs • Penalty costs for violating the maximum response time constraints / School of Industrial Engineering 10/15/2014 PAGE 17 Planning problems Tactical planning problem: Decision on base stock levels: Given in this study Operational planning problem: We consider two allocation rules Static: Common in practice Dynamic: Exploits real-time stock level information / School of Industrial Engineering 10/15/2014 PAGE 18 The two allocation rules Static Allocation (SA-rule): • • • • Fulfill demand from nearest LW with positive on-hand stock But, fulfill from CW if cheaper Easy to compute, easy to execute (Markov model) Weak differentiation between customer classes Dynamic Allocation (DA-rule): • Estimate near-future effect when fulfilling from one of the LW’s with positive on-hand stock (Use of Appr. Dyn. Progr.) • Select LW or CW with lowest “direct + near-future costs” • Requires computer support to be applied • Better differentiation between customer classes / School of Industrial Engineering 10/15/2014 PAGE 19 Computational experiment Large instances: Relative savings of DA-rule compared to SArule: 7.9% Conclusion: • Savings relative to the static rule are significant • Dynamic rule gives a better way to differentiate between customer classes • You get implicitly a kind of dynamic, reserved stock levels for high-priority customers / School of Industrial Engineering 10/15/2014 PAGE 20 3. Effect of product design: Redundancy decision (Öner, Scheller-Wolf, and van Houtum, OR, 2013) / School of Industrial Engineering 10/15/2014 PAGE 21 Setting Production site Spare parts stock Regular replenishments Emergency supply procedure (in case of stockout) / School of Industrial Engineering 10/15/2014 PAGE 22 Model (cont.) Component 1 Component 2 Component 2 Component i Component m Component m Per machine: • Multiple critical components • Serial structure / School of Industrial Engineering 10/15/2014 PAGE 23 Model (cont.) Three possible policies per component 1. No redundancy 2. No redundancy, apply emergency supply procedure when on-hand stock drops to 1 3. Redundancy Optimization problem Min. TCO s.t. system availability constraint / School of Industrial Engineering 10/15/2014 PAGE 24 Approach • Generation of the efficient frontier for TCO and system availability (via Lagr. Rel.) • One curve for case with policy 2 • One curve for case without policy 2 • One gets an order for which components have to be made redundant / School of Industrial Engineering 10/15/2014 PAGE 25 Analysis per component Costs Policy 1 Policy 2 Policy 3 Policy 1 optimal / School of Industrial Engineering Policy 2 optimal Policy 3 optimal 10/15/2014 PAGE 26 Efficient frontier Without policy 2 With policy 2 included Availability / School of Industrial Engineering 10/15/2014 PAGE 27 Efficient frontier Notice: Without The optimal designpolicy depends strongly 2 on the required availability So: Multiple customer classes => multiple With policy 2 designs included Availability / School of Industrial Engineering 10/15/2014 PAGE 28 4. New opportunity: Remote monitoring data (based on Topan, Dekker Tan, and Van Houtum, WP, 2014) / School of Industrial Engineering 10/15/2014 PAGE 29 Monitoring data Sample Data: Collected at central level, for one critical unit • Condition data: parameters which are directly or indirectly related with the health state of Module X • Failure data: failure time PAGE 30 MACHINE NUMBER TIME STAMP VALUE MACHINE TYPE SITE ID CUSTOMER CONTINENT CUSTOMER CUSTOMER PARAM COUNTRY NUMBER ID M1297 M2572 M2488 17-Dec-09 22-Oct-09 30-Jul-09 -8.856 T0010 -8.9597 T0005 -3.9977 T0083 1288 Asia 665 Asia 755 Other South Korea 188 Singapore 2046 Other OT01 M0822 14-Jul-09 -4.0141 T0016 1284 Asia South Korea 188 960 M1621 08-May-09 -3.8854 T0010 South Korea 1146 957 M1647 23-Oct-09 -3.9167 T0001 1294 Asia North 277 America USA 196 966 M0003 21-Jul-09 -3.873 T0010 1291 Asia South Korea 188 990 M0004 M2862 M2631 21-Feb-09 27-Aug-09 06-Jan-09 -3.8264 T0010 -3.7398 T0004 -8.551 T0004 1291 Asia 629 Asia 801 Europe South Korea 188 Taiwan 222 France 192 966 993 972 M1141 M3241 M0051 M1171 M1171 10-Aug-09 22-Apr-09 05-Sep-09 28-Feb-09 12-Aug-09 -6.8885 -8.551 -8.9597 -3.9977 -6.8885 1290 629 1178 629 629 South Korea Taiwan Taiwan Taiwan Taiwan 966 963 996 987 990 M1614 04-Dec-09 M1951 16-Jul-09 T0011 T0010 T0008 T0006 T0006 -8.551 T0007 -8.9597 T0019 Asia Asia Asia Asia Asia 1146 222 386 222 222 1284 Asia South Korea 188 1286 Asia / School of South KoreaIndustrial 188 Engineering 3756 990 981 990 960 10/15/2014 Imperfect warnings Demand signals produced by the prediction model are imperfect: • Prediction model can produce false signals (false positives) • Exact time of the failure is uncertain • Prediction model may also produce false negatives − Sudden, unpredicted failures which cannot be detected in advance by the monitoring system PAGE 31 / School of Industrial Engineering 10/15/2014 Research topic Value of the imperfect warnings for spare parts supply Remark: We do not look at preventive replacements. Setting: • Single stockpoint (a local warehouse, gets replenishments from a central warehouse) • Single item • Imperfect warnings = Imperfect Advance Demand Information (ADI) PAGE 32 / School of Industrial Engineering 10/15/2014 Imperfect ADI demand lead time Demand [ t ] l u p L supply lead time Supply t PAGE 33 p: probability that a signal will ever become a demand realization = reliability (false positives) [l, u] : prediction interval for the demand lead time (timing) q : ratio of predicted demand to total demand = sensitivity (false negatives) / School of Industrial Engineering 10/15/2014 Approach 3 scenarios: 1. Optimal cost without ADI (benchmark) 2. Optimal cost with imperfect ADI, but no returns allowed 3. Optimal cost with imperfect ADI, and returns allowed Each scenario: Analyzed by a Markov decision model PAGE 34 / School of Industrial Engineering 10/15/2014 Case study at an OEM • 4 parts that OEM supplies its customers all over the world. • p, q, [l, u] : obtained from prediction model in use • cem: transportation cost + high downtime cost cem = 75000 Euro • cr: transportation cost + pipeline holding cost • L : 2 weeks PAGE 35 / School of Industrial Engineering 10/15/2014 Case study at an OEM Part P T X W h [𝝉𝒍 , 𝝉𝒖 ] 𝝀 (€/unit/week) (week) (unit/week) 2720 112 152 646 [2,8] [8,16] [0,4] [0,1] 0.0188 0.0600 0.0019 0.0036 𝒑 𝒒 𝒄𝒓 0.42 0.90 0.45 0.90 0.44 0.90 0.43 0.50 5500 325 400 1400 𝒈𝑵𝒐𝑨𝑫𝑰 𝒈𝑨𝑫𝑰𝑵𝒐𝑹𝒆𝒕𝒖𝒓𝒏 (€/week) (€/week) 1406.01 248.13 145.29 273.28 1399.68 139.78 138.83 273.28 𝒈𝑨𝑫𝑰 𝑷𝑪𝑹𝑨𝑫𝑰𝑵𝒐𝑹𝒆𝒕𝒖𝒓𝒏 (€/week) 956.06 131.80 134.37 260.00 0.45% 43.67% 4.45% 0.00% 𝑷𝑪𝑹𝑨𝑫𝑰 32.00% 46.88% 7.52% 4.86% • Part P (p and q are low and information is timely) • value of information is high when returning excess inventory is allowed. • benefit of returns • Policy with ADI and no returns: Local warehouse carries no stock + a spare part is shipped to the local warehouse only if a warning is issued • Part T (p and q are high and information is timely), • value of information is high even for without return case. PAGE 36 / School of Industrial Engineering 10/15/2014 Case study at an OEM Part P T X W h [𝝉𝒍 , 𝝉𝒖 ] 𝝀 (€/unit/week) (week) (unit/week) 2720 112 152 646 [2,8] [8,16] [0,4] [0,1] 0.0188 0.0600 0.0019 0.0036 𝒑 𝒒 𝒄𝒓 0.42 0.90 0.45 0.90 0.44 0.90 0.43 0.50 5500 325 400 1400 𝒈𝑵𝒐𝑨𝑫𝑰 𝒈𝑨𝑫𝑰𝑵𝒐𝑹𝒆𝒕𝒖𝒓𝒏 (€/week) (€/week) 1406.01 248.13 145.29 273.28 1399.68 139.78 138.83 273.28 𝒈𝑨𝑫𝑰 𝑷𝑪𝑹𝑨𝑫𝑰𝑵𝒐𝑹𝒆𝒕𝒖𝒓𝒏 (€/week) 956.06 131.80 134.37 260.00 0.45% 43.67% 4.45% 0.00% 𝑷𝑪𝑹𝑨𝑫𝑰 32.00% 46.88% 7.52% 4.86% • Parts X and W (L > l), • value of information is low even when return is allowed => negative impact of timing of information on the value of information PAGE 37 / School of Industrial Engineering 10/15/2014 5. General OM research agenda / School of Industrial Engineering 10/15/2014 PAGE 38 Topic: Servitization in the capital goods industry Purpose of this talk: Showing how can we contribute with OM research 1. Creation of differentiation while keeping the portfolio effect 2. Effect of product design: Redundancy decision 3. New opportunity: Remote monitoring data / School of Industrial Engineering 10/15/2014 PAGE 39 General OM research agenda • Design of service networks and processes • • • • Creation of differentiation while keeping the portfolio effect Location strategy For spare parts, service engineers, tools, back office,… Where to decompose: For the offered services and between service provider and user • Effect of product design decisions in general • • • • • Redundancy decision, choice of components/suppliers,… Commonality across multiple machine types Level of modularity How to deal with modifications Design per type of service contract? / School of Industrial Engineering 10/15/2014 PAGE 40 General OM research agenda • Exploiting new technologies in general • • Remote monitoring data Use of 3D printers • Sharing of resources/data by multiple companies • Service costs and pricing • Sustainability issues: • Re-use of systems and components • CO2 and other emissions • … / School of Industrial Engineering 10/15/2014 PAGE 41 Questions/Discussion / School of Industrial Engineering 10/15/2014 PAGE 42

© Copyright 2026