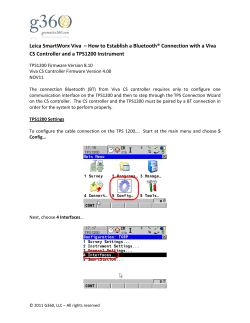

Constant & Variable air volume controllers Air volume the smart way