Underground Cables Presented By: Er. H.S. Dhaliwal Assistant Professor,

Underground Cables Presented By: Er. H.S. Dhaliwal Assistant Professor, Deptt. Of Electrical Engg BHSBIET, Lehragaga. Punjab EDUSAT Socity 1 Introduction • Since the loads having the trends towards growing density. This requires the better appearance, rugged construction, greater service reliability and increased safety. An underground cable essentially consists of one or more conductors covered with suitable insulation and surrounded by a protecting cover. The interference from external disturbances like storms, lightening, ice, trees etc. should be reduced to achieve trouble free service. The cables may be buried directly in the ground, or may be installed in ducts buried in the ground. Punjab EDUSAT Socity 2 Introduction Punjab EDUSAT Socity 3 CABLE STRUCTURE Punjab EDUSAT Socity 4 Advantages & Disadvantages Advantages – Better general appearance – Less liable to damage through storms or lighting – Low maintenance cost – Less chances of faults – Small voltage drops Disadvantages – The major drawback is that they have greater installation cost and introduce insulation problems at high voltages compared with equivalent overhead system. Punjab EDUSAT Socity 5 Construction of Cables • Core or Conductor A cable may have one or more than one core depending upon the type of service for which it is intended. The conductor could be of aluminum or copper and is stranded in order to provide flexibility to the cable. • Insulation The core is provided with suitable thickness of insulation, depending upon the voltage to be withstood by the cable. The commonly used material for insulation are impregnated paper, varnished cambric or rubber mineral compound. Punjab EDUSAT Socity 6 Construction of Cables • Metallic Sheath A metallic sheath of lead or aluminum is provided over the insulation to protect the cable from moisture, gases or others damaging liquids • Bedding Bedding is provided to protect the metallic sheath from corrosion and from mechanical damage due to armoring. It is a fibrous material like jute or hessian tape. Punjab EDUSAT Socity 7 Construction of Cables • Armouring Its purpose is to protect the cable from mechanical injury while laying it or during the course of handling. It consists of one or two layers of galvanized steel wire or steel tape. • Serving To protect armouring from atmospheric conditions, a layer of fibrous material is provided. Punjab EDUSAT Socity 8 Construction of Cables Punjab EDUSAT Socity 9 Properties of Insulating Material High resistivity. High dielectric strength. Low thermal co-efficient. Low water absorption. Low permittivity. Non – inflammable. Chemical stability. High mechanical strength. High viscosity at impregnation temperature. Capability to with stand high rupturing voltage. High tensile strength and plasticity. Punjab EDUSAT Socity 10 Properties of Insulating Material Punjab EDUSAT Socity 11 Insulating Materials for Cables • Rubber It can be obtained from milky sap of tropical trees or from oil products. It has the dielectric strength of 30 KV/mm. Insulation resistivity of 10 exp 17 ohm.cm Relative permittivity varying between 2 and 3. They readily absorbs moisture, soft and liable to damage due to rough handling and ages when exposed to light. Maximum safe temperature is very low about 38 C Punjab EDUSAT Socity 12 Insulating Materials for Cables • Vulcanized India Rubber It can be obtained from mixing pure rubber with mineral compounds i-e zinc oxide, red lead and sulphur and heated upto 150 C. It has greater mechanical strength, durability and wear resistant property. The sulphur reacts quickly with copper so tinned copper conductors are used. It is suitable for low and moderate voltage cables. Punjab EDUSAT Socity 13 Insulating Materials for Cables • Impregnated Paper This material has superseded the rubber, consists of chemically pulped paper impregnated with napthenic and paraffinic materials. It has low cost, low capacitance, high dielectric strength and high insulation resistance. The only disadvantage is the paper is hygroscopic, for this reason paper insulation is always provided protective covering. • Varnished Cambric This is simply the cotton cloth impregnated and coated with varnish. As the varnish cambric is also hygroscopic so need some protection. Its dielectric strength is about 4KV / mm and permittivity is 2.5 to 3.8. Punjab EDUSAT Socity 14 Insulating Materials for Cables • Polyvinyl chloride (PVC) This material has good dielectric strength, high insulation resistance and high melting temperatures. These have not so good mechanical properties as those of rubber. It is inert to oxygen and almost inert to many alkalis and acids. • XLPE Cables (Cross Linked Poly-ethene) This material has temperature range beyond 250 – 300 C This material gives good insulating properties It is light in weight, small overall dimensions, low dielectric constant and high mechanical strength, low water absorption. These cables permit conductor temperature of 90 C and 250 C under normal and short circuit conditions. These cables are suitable up to voltages of 33 KV. Punjab EDUSAT Socity 15 XLPE cable Punjab EDUSAT Socity 16 CLSSIFICATION OF CABLES • Low tension (L.T) ----- up to 1000V • High tension (H.T) ----- up to 11, 000V • Super tension (S.T) ---- from 22KV to 33KV • Extra high tension (E.H.T) cables --- from 33KV to 66KV • Extra super voltage cables ------beyond 132KV Punjab EDUSAT Socity 17 Extra High Tension Cable Punjab EDUSAT Socity 18 Low Tension Cable Punjab EDUSAT Socity 19 3- Core Cables Belted Cables In these cables the conductors are wrapped with oil impregnated paper, and then cores are assembled with filler material. The assembly is enclosed by paper insulating belt. These can be used for voltages up to 11KV or in some cases can be used up to 22KV. High voltages beyond 22KV, the tangential stresses becomes an important consideration. As the insulation resistance of paper is quite small along the layer, therefore tangential stress set up, hence, leakage current along the layer of the paper insulation. This leakage current causes local heating, resulting breaking of insulation at any moment Punjab EDUSAT Socity 20 3-core belted Cable Punjab EDUSAT Socity 21 3- Core Cables • Screened Cables • These can be used up to 33kv but in certain cases can be extended up to 66kv. • These are mainly of two types H-type and S.L type cables Punjab EDUSAT Socity 22 3- Core Cables H-TYPE Cables: • Designed by H. Hochstadter. • Each core is insulated by layer of impregnated paper. • The insulation on each core is covered with a metallic screen which is usually of perforated aluminum foil. • The cores are laid in such a way that metallic screen make contact with one another. • Basic advantage of H-TYPE is that the perforation in the metallic screen assists in the complete impregnation of the cable with the compound and thus the possibility of air pockets or voids in the dielectric is eliminated. • The metallic screen increase the heat dissipation power of the cable. Punjab EDUSAT Socity 23 3- Core Cables (H-Type) Punjab EDUSAT Socity 24 3- Core Cables S.L - Type: (Separate Lead) • • • Each core insulation is covered by its own lead sheath. It has two main advantages, firstly the separate sheath minimize the possibility of core-to-core breakdown. Secondly the, bending of cables become easy due to the elimination of over all sheath. The disadvantage is that the lead sheaths of S.L is much thinner as compared to H-Type cables, therefore for greater care is required in manufacturing. Punjab EDUSAT Socity 25 3- Core Cables (S.L. Type) Punjab EDUSAT Socity 26 3- Core Cables • Pressurized Type Cables • In these cables, pressure is maintained above atmosphere either by oil or by gas. • Gas pressure cables are used up to 275KV. • Oil filled cables are used up to 500KV. Punjab EDUSAT Socity 27 3- Core Cables (Gas pressure) Punjab EDUSAT Socity 28 3- Core Cables • Oil Filled Cables • Low viscosity oil is kept under pressure and fills the voids in oil impregnated paper under all conditions of varying load. • There are three main types of oil filled cables a. Self-contained circular type b. Self-contained flat type c. Pipe Type cables Punjab EDUSAT Socity 29 3- Core Cables (Oil filled) Punjab EDUSAT Socity 30 Advantages of Oil Filled Cables • Greater operating dielectric stresses • Greater working temperature and current carrying capacity • Better impregnation • Impregnation is possible after sheath • No void formation • Smaller size of cable due to reduced dielectric thickness • Defect can easily be detected by oil leakage Punjab EDUSAT Socity 31 Gas Pressure Cables In these cables an inert gas like nitrogen is used to exert pressure on paper dielectric to prevent void formation. These are also termed as Compression cables They insulated cores similar to solid type The cable is inserted in a pressure vessel which may be a rigid steel pipe, commonly known as pipe line compression cable. The nitrogen gas is filled in vessel at nominal pressure of 1.38 * 10 exp 6 N/ square meter with a maximum pressure of 1.725 * 10 exp 6 N/ square meter. Punjab EDUSAT Socity 32 Gas Pressure Cables Punjab EDUSAT Socity 33 Gas Insulated Cables (GIC) • In GIC cables high pressure sulphur hexaflouride (SF6), fills the small spaces in oil impregnated paper insulation and suppresses the ionization. • Most EHV and UHV lines insulated with sulphur hexaflouride (SF6) gas are being used extensively for voltages above 132 KV up to 1200 KV. • These cables are very popular for short lengths, river crossings and high way crossings. Punjab EDUSAT Socity 34 Gas Insulated Cables (GIC) Punjab EDUSAT Socity 35 Advantages of GIC • • • • Gas Insulated Cables have several advantages over oil filled cables, Efficient heat transfer hence can carry more current. Low dielectric loss and low capacitance SF6 gas is non-toxic, chemically stable and non-inflamable. Terminations of GIC cables are simpler and cheaper. Punjab EDUSAT Socity 36 Laying of Underground Cables • The reliability of underground cable network depends to a considerable extent upon proper laying. • There are three main methods of Laying underground cables a. Direct Laying b. Draw in system c. Solid system Punjab EDUSAT Socity 37 Direct Laying • • • • • This method is cheap and simple and is most likely to be used in practice. A trench of about 1.5 meters deep and 45 cm wide is dug. A cable is been laid inside the trench and is covered with concrete material or bricks in order to protect it from mechanical injury. This gives the best heat dissipating conditions beneath the earth. It is clean and safe method Punjab EDUSAT Socity 38 Direct Laying Punjab EDUSAT Socity 39 Disadvantages of Direct Laying • • • Localization of fault is difficult It can be costlier in congested areas where excavation is expensive and inconvenient. The maintenance cost is high Punjab EDUSAT Socity 40 Draw in System • In this conduit or duct of concrete is laid in ground with main holes at suitable positions along the cable route. • The cables are then pulled into positions from main holes. Punjab EDUSAT Socity 41 Advantages of Draw in System • It is very high initial cost • Heat dissipation conditions are not good • This method is suitable for congested areas where excavation is expensive and inconvenient • This is generally used for short lengths cable route such as in workshops, road crossings where frequent digging is costlier and impossible Punjab EDUSAT Socity 42 Solid System • In this system the cable is laid in open pipes or troughs dug out in earth along the cable route. • The troughing is of cast iron or treated wood • Troughing is filled with a bituminous after cables is laid. • It provides good mechanical strength • It has poor heat dissipation conditions • It requires skilled labour and favorable weather conditions • It is very much expensive system Punjab EDUSAT Socity 43 Solid System Punjab EDUSAT Socity 44 Grading of Cables • Since the stresses are maximum at surface of the conductor or inner most part of the dielectric. • The stress goes on decreasing as outer most layer is reached. • Since the process of achieving the uniform electrostatic stresses on the dielectric of cables is known as Grading of cables Punjab EDUSAT Socity 45 Grading of Cables • The unequal distribution of stresses is undesirable because, • if dielectric is chosen according to maximum stress the thickness of cable increases or either this may lead to breakdown of insulation. • The following are the two main methods of grading Capacitance grading Inter sheath grading Punjab EDUSAT Socity 46 Cables are generally laid in the ground or in ducts in the underground distribution system. For this reason, there are little chances of faults in underground cables. However, if a fault does occur it is difficult to locate and repair the fault because conductors are not visible. Nevertheless, the following are the faults most likely to occur in underground cables 1) open circuit fault 2) short circuit fault 3)earth fault Punjab EDUSAT Socity 47 • When there is a break in the conductor of a cable, it is called open circuit fault. • The open circuit fault can be checked by megger. For this purpose, the three conductors of the 3core cable at the far end are shorted and earthed. • The resistance between each conductor and earth is measured by a megger and it will indicate zero resistance in the circuit of the conductor that is not broken. • However, if the conductor is broken, the megger will indicate infinite resistance in its circuit Punjab EDUSAT Socity 48 • When two conductors of a multi-core cable come in electrical contact with each other due to insulation failure, it is called a short circuit fault. • Again, we can seek the help of a megger to check this fault. • For this purpose the two terminals of the megger are connected to any two conductors. • If the megger gives zero reading, it indicates short circuit fault between these conductors. • The same steps is repeated for other conductors taking two a time. Punjab EDUSAT Socity 49 EARTH FAULTS • When the conductor of a cable comes in contact with earth, it is called earth fault or ground fault. • To identify this fault, one terminal of the megger is connected to the conductor and the other terminal connected to earth. • If the megger indicates zero reading, it means the conductor is earthed. The same procedure is repeated for other conductors of the cable. Punjab EDUSAT Socity 50 Physical Limitations of Underground Lines The main argument against constructing underground systems is usually financial. But costs are not the only limitation. The laws of physics limit how physically long a power line can be. These limits are relatively unimportant on overhead lines but will severely limit high voltage underground cable systems The higher the voltage the shorter the line length must be. The limiting effects become very important at transmission voltages, especially 100,000 Volts and above. Limiting effects may also be important for subtransmission voltages, 69,000 Volts and 35,000 Volts. Punjab EDUSAT Socity 51 Physical Limitations: The Effect of Capacitance o Capacitance causes current to flow even when no load is connected to the cable. This is called “line charging current”. o Underground line capacitance for power cables is far higher than overhead line capacitance. o Wires are closer to each other o Wires are closer to the earth (within a few inches). o Underground lines have 20-75 times the line charging current that an overhead line has (depending on line voltage). o If a line is long enough the charging current could be equal to the total amount of current the line can carry. This will severely limit its ability to deliver power. Punjab EDUSAT Socity 52 Summary of Costs: Overhead vs. Underground • Transmission: Underground may be 4-20 times Overhead. • Sub transmission: Underground may be 4-20 times Overhead • Distribution: Underground may be 2-10 times Overhead • New underground may be cheaper than overhead in special conditions and costs vary greatly from utility to utility and place to place. Punjab EDUSAT Socity 53 THANKS Presented By: Er. H.S. Dhaliwal [email protected] 098150-74800 Punjab EDUSAT Socity 54

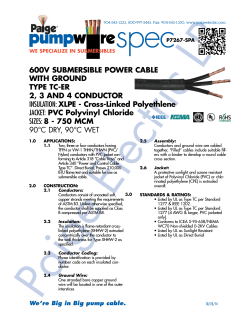

© Copyright 2026