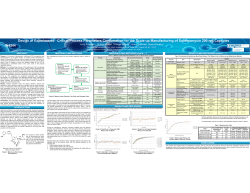

ABSTRACT METHODS

Design for 6 Sigma: The Utility of Process Capability Analysis Early in Pharmaceutical Process Development Majuru, 1Lovy Pradeep, 1David Pereira, 2Christin Hollis, 2Harry Cocolas, 3Ray Thomas, 3Joseph Schlee RESULTS CONTINUED Solithromycin is currently in Phase 3 of clinical development for the treatment of community-acquired bacterial pneumonia and uncomplicated gonorrhea. The dosage forms under development include hard gelatin capsules, a lyophilized formulation for parenteral administration and a powder for oral suspension for the pediatric population. The capsule dosage form consists of a solithromycin granulation with suitable excipients encapsulated into a size 0 hard gelatin capsule with a fill weight of 325 mg and a strength of 200 mg. In the course of development, clinical supplies were successfully manufactured at batch sizes ranging from 5,000 to 150,000 capsules, and no major process related issues were encountered. Based on the stage of clinical testing, the qualitative and quantitative composition of the capsule formulation has already been fixed, however the manufacturing process needed to be optimized. In order to support the continued product development, it was necessary to manufacture batches for registration stability testing. In preparation for registration batch manufacture, it was necessary to review the batch history and to optimize the manufacturing process. In this regard, a Design-of-Experiments (DOE) approach was utilized to characterize the design space and identify the operation ranges for parameters during the granulation, drying, blending and encapsulation. A scale-up and three registration batches (160,000 capsules) were then manufactured using the identified parameters. The objective of this study was to utilize a Design-For-Six-Sigma (DFSS) approach and process capability analysis of the scale-up and registration batches as a tool for an early assessment of the process’ potential for Six Sigma Capability. This analysis will guide further development activities and validation batch manufacture. 100 95 Table 1: In-process and bulk product results for solithromycin capsules Batch#1402287 Batch#1402288 Parameter Acceptance Criteria Batch *1401679 In-process Testing Data Xbar Chart LSL UCL=100.789 Overall Within Specifications LSL 95 USL 105 LCL=98.509 3 4 5 6 7 8 9 10 90 93 96 R Chart 99 UCL=3.570 Blend Uniformity Assay Dissolution NMT 2.5 % w/w 2.08 Mean 100.6 Std. Dev 0.81 Min 99.84 Max 101.98 Bulk Capsule Testing Data 90.0-110.0 % of Label Claim 100.8 Mean 97 NLT 75% Q in 45 RSD 1.3 minutes Min 85 Max 98 NMT 6% w/w 3.0 USP/NF <905> *Record for the blend that was encapsulated under record 1402067 3.1 1.90 1.62 1.70 99.41 0.42 98.85 100.23 99.05 0.43 97.95 99.53 99.56 0.27 99.22 99.94 100.1 96 1.0 95 97 3.3 97.9 95 1.5 93 96 3.3 99.1 94 1.1 93 95 3.3 2.4 3.4 2.1 108 3 4 5 6 7 8 9 98 100 102 Capability Plot Overall Within StDev 0.7961 Cp 2.09 Cpk 1.95 PPM 0.00 100 415 20 10 Last 10 Subgroups 102 420 Within 5 Overall StDev 0.7591 Pp 2.20 Ppk 2.04 Cpm * PPM 0.00 9 17 6 8 33 41 49 57 73 The in-process filled capsule weight checks for the scale-up and registration batches indicated that the process was in control with all of the observations within the control limits (Figure 4). 20 30 40 AD: 0.981, P: 0.014 UCL=19.88 _ R=8.71 10 9 17 25 33 41 49 57 65 73 410 Last 25 Subgroups 420 410 420 Overall 430 Within Overall StDev 4.270 Pp 3.28 Ppk 3.26 Cpm * PPM 0.00 Specs 65 70 Batch # f2 f1 65 6 1402287 76 3 Similar to clinical batch based on f2 > 50 Not different from clinical batch based on f1 < 15 70 Comments Capability Plot Within StDev 4.206 Cp 3.33 Cpk 3.31 PPM 0.00 60 60 1402067 LCL=0 1 50 Normal Prob Plot 430 Figure 3: Process capability sixpack: blend uniformity 10 Figure 7: Dissolution profile in pH 2.5 phosphate buffer Table 2: Comparison of Dissolution profiles with Clinical Batch (14703.004) as the reference 385 396 407 418 429 440 451 462 0 10 Sample 0 Time (min) Specifications LSL 377.76 USL 461.73 LCL=413.61 65 Scale-up Batch 1402067 Reg. Batch 1402287 Reg. Batch 1402288 Reg. Batch 1402289 40 0 Overall Within R Chart Specs 4 25 1 60 USL __ X=419.95 1 LCL=0 2 2 Report Results (% of Theoretical) 105 _ R=1.565 98 Moisture of dried granulation 102 AD: 1.580, P: < 0.005 LSL 80 20 Capability Histogram UCL=426.30 5 425 Normal Prob Plot 2 Batch # 1402288 Xbar Chart USL 99 2 Batch # 1402289 Process Capability Sixpack Report for Filled Capsule Weight __ X=99.649 4 Batch # 1402067 The process capability sixpack for the filled capsule weight is shown in Figure 6. As seen in the Figure, the process has a Cp of 3.33 and a Cpk of 3.31. This indicates that the process is capable of producing capsules within specifications and a fill weight distribution that is centered around the target. S a m p le M e a n 100 1 Batch # 1402287 Capability Histogram 101 1 Batch 1402289 100 410 Figure 5: Boxplot for in-process filled capsule weight The process capability sixpack is shown in Figure 3. Based on the results, the Cp was 2.09 and the Cpk 1.95, indicating that the process is capable of producing blends with a uniformity within 95-105 % of the theoretical value. Dissolution profiles were also generated in pH 2.5 phosphate buffer using USP apparatus I at 50 RPM for all the four batches and the profiles are shown in Figure 7. The data indicates that the dissolution profiles of all the four batches are comparable. The profiles of capsules from the B-M-E of encapsulation were consistent with those of Figure 7. Furthermore, the similarity of the profiles to a reference clinical batch was determined using f2 and f1 testing. Based on the analysis (Table 2), the dissolution profiles of all the four batches are similar to the reference clinical batch (f2 >50). Also the profiles are not different (f1<15). 420 Batch#1402289 Figure 2: Boxplots for blend uniformity for batches 1401679, 1402287, 1402288, and 1402289 0 Results Batch Batch 1402287 1402288 430 400 Batch#1401679 Process Capability Sixpack for Blend Uniformity The manufacturing process yielded acceptable blends that were successfully encapsulated into size 0 hard gelatin capsules. The in-process blend uniformity and capsules assay, moisture content and dissolution results are shown in Table 1 below. The results indicated that the process was capable of producing blends that met the in-process specifications and further produced capsules that met pre-established critical quality attributes. As shown in Table 1, the results indicate that the granulation, drying, milling and blending processes yield in-process materials that meet moisture and blend uniformity results pre-established criteria. Granulation moisture results ranged from 1.62 to 2.08 % w/w while blend uniformity results for all four batches ranged from 97.95-101.98% of theoretical. Moisture Uniformity of Dosage units (by weight variation) Figure 1: Solithromycin 105 S a m p le R a n g e Solithromycin, a new chemical entity under development by Cempra Pharmaceuticals, is a fourth-generation macrolide antibiotic, and the first fluoroketolide. The chemical structure of solithromycin is shown in Figure 1 below. 440 90 Values INTRODUCTION RESULTS AND DISCUSSION Filled Capsule Weight (mg) Boxplot Boxplot of Blend Uniformity V a lu e s Conclusion: Process capability analysis indicated that the process used for registration batch manufacture was capable of meeting specifications (Cp >1.33) and is centered with a Cpk greater than 1.33. The process has potential for Six Sigma performance, thus demonstrating the utility of process capability analysis early in development. Figure 5 shows a boxplot for in-process weight variation. Based on the box plot, the median values are close to the theoretical value and the spread of the data across the four batches is similar. 110 75 1402288 76 4 1402289 68 5 80 Sample Figure 6: Fill weight capability sixpack Run Chart for Batch # 1402067,1402287, 1402289, 1402288 450 Filled capsule weight (mg) Results: The results for blend uniformity, assay, dosage uniformity and dissolution indicated that all batches manufactured, were within specifications. Process capability analysis for the granulation and blending (blend uniformity) as well as the encapsulation yielded Cp values greater than 1.33. Additionally, process analysis indicated that it was centered as indicated by a Cpk greater than 1.33. The histogram and trend charts generated also indicated that the process was capable of meeting specifications and that it was centered. Analysis of control charts indicated that the encapsulation process was in control and that the process statistic was normal with at least 99.73% of all the points within the control limits. Dissolution profiles of the batches indicated that they were consistent from batch-tobatch and with those of solithromycin capsule batches used in clinical testing. The resulting blend was filled into Capsugel size 0 hard gelatin capsules using an Index K120i encapsulation machine. After machine setup, capsules (10) were taken every 30 minutes and the individual gross filled capsule weight determined. The target filled capsule weight was 420 mg with ±5% the upper and lower weight control limit across all four batches. Capsules were weight-sorted using an IMA Precisa 120 weight sorter and inspected on an inspection belt. Capsules were also submitted for bulk release testing, which included assay, content uniformity by weight variation, moisture, and dissolution (single point). Additionally, dissolution profiles were collected for bulk capsules and for capsules from the beginning, middle, and end (B-M-E) of encapsulation. Dissolution testing was conducted in 900 mL (50 mM) of phosphate buffer with a pH of 2.5 at 37 ± 0.5 oC using USP apparatus 1 at 50 RPM. The data collected was analyzed using Minitab® 17 Software. Process boxplots, probability plots, process control charts and the process capability metrics (Cp and Cpk) were used to characterize the process. Additionally, the dissolution profiles of the capsules manufactured were compared to those of capsules used in clinical studies. Figure 2 shows the boxplot of the blend uniformity for the four batches. It is noted that the scale-up batch (1401679) exhibited greater variability in blend uniformity than the registration batches (1402287, 1402289 and 1402288). % Solithromycin Released METHODS The manufacturing process involves high shear granulation, fluid bed drying, milling, blending and encapsulation. Solithromycin and excipients, except for the magnesium stearate were screened through a 20 mesh screen and transferred to a granulation bowl. Granulation was performed using a VG 200 high shear granulator with povidone dissolved in water as the binder solution. Following granulation, the material was divided into four sub-lots of approximately 25 kg each and dried using a fluid bed drier (GPCG-15) equipped with a 45 L bowl. The dried granules were passed through an 18 mesh screen. The granules retained on the 18 mesh screen were milled using a Comil equipped with a 0.5 mm round hole screen. All of the screened and milled dry granules were transferred to a V-blender and the required amount of magnesium stearate was added followed by blending for three minutes. Ten samples for blend uniformity testing were taken from the top middle and bottom of the blend. Filled Capsule W eight (mg) ABSTRACT Purpose: Solithromycin is a fourth-generation macrolide antibiotic, and the first fluoroketolide. Current development is focused on treatment of community-acquired bacterial pneumonia and uncomplicated gonorrhea. In preparation for capsule registration batches it was necessary to optimize the manufacturing process. The objective of this study was to utilize a Design-For-Six-Sigma (DFSS) approach and process capability analysis as a tool for an early assessment of the process’ potential for Six Sigma Capability. Methods: The manufacturing process involves high shear granulation, fluid bed drying, milling, lubrication and encapsulation. Critical quality process parameters were identified, and a Design-of-Experiments (DOE) was used as a guide towards understanding of the design space. Confirmation and registration batches were manufactured; blend uniformity, in-process fill weight, assay and dissolution data were collected and analyzed using Minitab® 17 Software. Process histograms, probability plots, process control charts and the process capability metrics (Cp and Cpk) were used to characterize the process. Additionally, the dissolution profiles of the capsules manufactured were compared to those of capsules used in clinical studies. W4305 Inc., 6320 Quadrangle Drive, Suite 360, Chapel Hill, NC 27517 Pharma Solutions, 1100 Enterprise Drive, Winchester, KY 40391 Pharma Solutions, 160 Pharma Drive, Morrisville, NC 27560 Blen d U n ifirm ity ( % o f the o re tic al) 3Catalent Mean Blend Uniformity (%) 1Cempra, 2Catalent Sample Range 1Shingai W4305 CONCLUSIONS UCL = 440 mg 440 One scale-up and three registration scale batches (52 kg) were successfully manufactured and predetermined critical product attributes were met. Process capability analysis indicated that the process used for registration batches manufacture was capable of meeting specifications (Cp >1.33) and is centered with a Cpk greater than 1.33. The capability of the process will continue to be monitored during scale-up to commercial batch size and the manufacture of validation and launch batches. The data generated so far indicates that the process has potential for Six Sigma performance, thus demonstrating the utility of process capability analysis early in development. 430 420 410 LCL= 400 mg 400 390 1 5 10 15 20 25 30 35 40 45 50 55 60 Sample Number of runs about median: 39 Expected number of runs: 41.0 Longest run about median: 8 Approx P-Value for Clustering: 0.326 Approx P-Value for Mixtures: 0.674 Number of runs up or down: 61 Expected number of runs: 53.0 Longest run up or down: 2 Approx P-Value for Trends: 0.984 Approx P-Value for Oscillation: 0.016 Figure 4: Filled capsule weight run chart 65 70 75 80 REFERENCES 1. Chowdhury, M.R., Process Capability Analysis in Pharmaceutical Production. International Journal of Pharmaceutical and Life Sciences Vol.2(2) 2013: 85-89

© Copyright 2026