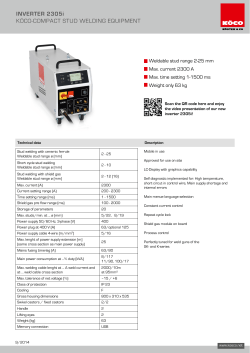

ROYAL ARC ELECTRODES LTD