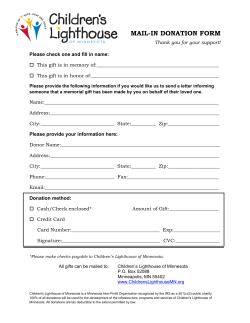

The Network News November 2014

The Network News Tri-State Manufacturers’ Association Newsletter November 2014 This Issue TSMA’s November Company of the Month found success by counteracting the “burnt toast” theory. Are you intrigued? Read on to learn about the heat-generating products manufactured by Thawzall, LLC. Founded as T.H.E. Machine Company in Glenwood, MN, in 1997, Jerome Jakobson conceived the idea of a portable hydronic heating system when a contractor friend found himself behind schedule as the winter freeze caught up with him. A plumber by trade, Jakobson produced hundreds of hydronic heater prototypes before settling on a version that used a low pressure, closed-loop system to deliver heat. Believing his portable hydronic heater to be better than a competitor’s product, Jakobson received a patent in 1999 for a model with a manifold fluid distribution system that featured quick disconnects and multiple heat zones. The patented technology is called HEATZONE®. In 2007, Jakobson sold his company to five local Alexandria investors and on July 1, the name changed to Thawzall LLC under new ownership and management. Current GM David Reller joined the company in 2011, and Thawzall relocated to a 20,000 square foot facility in Alexandria in 2012. After the great recession, Thawzall embraced a new business model in which they eliminated their in-house fabrication department and began outsourcing all components. The present day shop floor specializes in efficient, on-demand assembly of several standard units, with options available. So – back to the “burnt toast” theory. Competing “ground thaw” products deliver heat in an uncontrolled method that results in uneven heat distribution – reminiscent of the unpredictable toaster we’ve all encountered that randomly burns your toast. 4 Education Partnership Mtg 5 Celebrating MN Mfg Week! 6 Nominations for Member of Year 6 TSMA Elections Underway 7 Billboard Cost-Share % Increase 10 Scholarship Deadline - Nov. 14 11 Board Highlights of Oct Meeting Thawzall is the only company in the business that offers a product with HEATZONE® technology - multiple heat zones that can be controlled with the push of a button. Thawzall’s portable heating and curing system is available in two models, the TCH150 and TCH 250. Both models are mounted on a trailer to enable movement from one job site to the next. These systems operate by using a diesel powered oil burner to heat a mixture of glycol (40%) and water (60%) running through multiple hoses. The hoses are laid out in a zig-zag pattern on the frozen ground, similar to the layout used for in-floor heat systems installed in homes and buildings. The smaller unit utilizes two 600’ hoses and the larger unit is equipped with five separate 600’ hoses. Once the hoses are laid out on the frozen ground, they are covered with construction blankets to retain the 180° heat being generated. The TCH150 has the capacity to thaw Continued on Page 2 TSMA is affiliated with Midwest Manufacturers' Association. m Page 2 November 2014 Thawzall, LLC Con’t from pg 1 12” of frost in 24 hours in a 2,400 square foot area, while the TCH250 can impact 6,000 square feet. Thawing the ground isn’t the only challenge for construction projects impeded by winter weather, so the HEATZONE® technology has also been adapted for use in curing concrete. To continue the above scenario, excavators at the build site remove the top 12” of now frost-free soil. The hoses are then repositioned for another 24 hours and an additional 12” thawed followed by excavation, and so on until the desired depth is reached. Concrete is poured, but cold temperatures greatly impact the amount of time needed for curing. HEATZONE® hoses are positioned on the concrete and covered with blankets to create the 75° F environment ideal for the concrete curing process. When Thawzall was impacted in 2009-2010 by the decline in construction during the recession, the owners decided to use that down-time to diversify the company with a second heat-generating product line: the HEATZONE® Flameless Heater. Available in two sizes, the H750 (patent pending) and the patented H1350, Thawzall’s flameless heaters utilize a considerably more efficient (up to 94%efficient) technology that was developed just four years ago. The Flameless Heater is also a portable unit mounted on a trailer. It operates with an internal combustion diesel engine that ingeniously captures four sources of heat: mechanical shaft to thermal heat conversion, exhaust heat, radiant heat from the engine block, and coolant heat. Fans are used to expel the captured heat through two output ducts, with the operator having control over both discharge temperature (max 250° F or 275° F) and rate of expulsion. The largest application for Flameless Heaters is the oil and gas industry. A single H1350 unit at a Wyoming well site is used to simultaneously heat six well-heads—this unit replaces six competing units used for the same application. Thawzall is the only company to provide a Flameless Heater that actually works in the harsh conditions at the Prudhoe Bay oil field, a cold, remote location in extreme northern Alaska. Five units recently shipped to the natural gas industry in Kazakhstan (a former republic of the USSR); the customer’s freight forwarder played an integral role for successful shipment. Currently, Thawzall exports about ten percent of total production. An important feature of Thawzall flameless products is the use of safe, clean, fume-free heat. In numerous scenarios, particularly mines and drilling rigs where methane may be encountered, flameless heat is an important safety measure. Fuel efficiency is also a critical feature. Because the HEATZONE® technology Phone: 800-654-5773 is based on the most efficient heat transfer methodology, Thawzall products operate with up to seven times LESS fuel than competing products. This translates to huge fuel savings … fuel costs are greatly reduced in conjunction with a much more favorable impact on the environment. With the success of the Flameless Heaters, which now account for approximately fifty percent of sales, Thawzall is renting additional assembly space in a secondary location in Alexandria. Although still impacted by a seasonal sales spike – the “busy season” runs from spring to late winter - the company’s 20-employee workforce is now stable throughout the year with no layoffs. Production averages five to ten units a week. The company also offers accessories, such as generators for when electricity is not available on location, transformers to accommodate European electrical requirements, and a remote manifold to extend the reach of the hoses. The sales force consists of Reller, and another employee, Steve Knisley, and several regional independent sales reps. Of interest, the company’s largest customers are big rental agencies like Hertz Equipment and United Rental and many large independent rental companies. Reller explained the current business model in which contractors and mining companies have gone away from managing their own assets. Much of the equipment needed to get a job done, including Thawzall units, is rented, expensed to the specific job, maintained by the rental company, and returned when the job is over. That said, the sales force still spends considerable time visiting construction sites and mines in an effort to generate demand for Thawzall products. Thawzall LLC has experienced significant growth of late. To date, company sales in 2014 are double what they were one year ago. This summer, the company accepted an order for 50 ground thaw units that will ship to the gas fields in West Virginia. In this application, the hoses are not intended for thawing or curing, but rather, to keep the blow off protection valves on a drilling rig operable and water in pipelines and frack tanks from freezing. With oil and gas markets still expanding due to the new drilling processes, the future looks promising for Thawzall. Their biggest challenge is figuring out a way to accommodate significant growth in terms of facility space, available workforce, and cash flow. Meanwhile, many happy customers are pleased to have an option other than “burnt toast!” Written by Sandy Kashmark, TSMA Exec. Director [email protected] www.tsma.org m Page 3 November 2014 Thawzall Photos Thawzall’s H1350 Flameless Heater utilizes technology developed just four years ago to bring portable heat to mining operations across the globe. HEATZONE® technology in the TCH250 employs five 600’ hoses filled with a glycol/water mixture to deliver controlled heat to construction and mining sites. The arrival of November reminds us of a special day. It was planned to be a day of thanks. I look forward to the feast of delicious food, family, good friends, and way too much football. E Says... Elroy Vesta EJ Enterprises, Fergus Falls Reliving the Past To Enhance the Present This month I want to consider how the gratitude we have for our past can and does shape our present. The impact of gratitude on our lives is significant. We do not come to a lifestyle of gratitude on a whim. This pattern likely had its beginning in childhood and was sharpened with the impact of mentors throughout our lives. T – Time is needed to become one whom people remember with fondness because we reflect our grateful spirit in all that we do. For me, gratitude was first learned from parents who reminded (commanded) me to say “thanks.” Teachers, a boss at the newspaper, a look from a family member, and many others have been constantly influencing me to be more grateful. H – Help is needed for this to develop. I have read extensively. Textbooks, biographies, magazines, self- help books, and the Bible all have provided reminders that THANKS should be part of my life. I remember that boss who in gentle but firm ways helped me to understand that more effort would be given by the newspaper carriers if I expressed thanks rather than commands. This is a lifelong lesson that continues to shape who I am becoming. A – Attitude guides how we can develop into thankful people. There are still people around us who are takers. I don’t know about Phone: 800-654-5773 [email protected] you, but I find these people burdensome. The takers’ attitude is marked with a selfishness that hinders partnership and participation. Attitude adjustment requires a willingness to be responsible for how one views life. I find it helpful to take moments to walk, rest, or spend time with a positive influence and my attitude changes. N – Names are important. When you say thank you, be certain that you call the person by name. We all like to be remembered by the name we bear. I’ve been embarrassed by using an incorrect name; it is best to own up to the mistake and learn from the error. All of us like to hear our name used in a positive manner, so make this part of the way you show gratefulness. K – Kindness involves showing appreciation in a manner that is generous and considerate. I have heard thanks expressed in a grudgelike manner. It does not feel good when this happens. In all instances I have observed, the lack of kindness leads to questioning whether there was a true expression of gratitude. S – Supportive is the way gratitude unfolds when I recognize its value to the person to whom I am expressing appreciation. When THANKS is expressed, I know someone took note of my work and words and values what I have offered. When is the right time to value another by means of expressing gratefulness for their investment in your work and world? Always. From my house and office to your lives – THANKS! You have made a difference in life for me and I am blessed to be part of your life. www.tsma.org m Page 4 November 2014 Tuesday, November 4 Alexandria Alexandria Area High School 4300 Pioneer Rd SE Schedule of Events 4:30 PM 5:30 PM 6:15 PM 7:15 PM Tour: Alexandria Area High School Dinner/Networking in Commons TSMA General Mtg/Guest Speakers Adjourn Discussion Topic Connecting Manufacturing and K-12 Education Presented by: Jason Murray, Exec. Director, EDC Alexandria Area Duane Taillefer, VP Operations, Massman The audience will learn how the Alexandria community came together to plan, develop and fundraise to support curriculum focusing on career development in the region. Presenters will share background on the academy model built by the community, curriculum in manufacturing, and key equipment acquired to support the academy. RSVP by Friday, Oct. 31 Register Here Tour: NEW Alexandria Area High School The new school building is a model in environmentally friendly design and construction, and will accommodate 1,400 students in grades 9 through 12. It features a cutting edge learning environment. With over 4 million dollars in private donations the school has some exceptional features not usually seen in high schools - making this a tour well worth your while. TSMA Education Partnership Hats off to our current K-12 partners: Alexandria District 206 Brandon-Evansville High School Breckenridge School District Campbell-Tintah School Tri-State Mfg. Association Detroit Lakes High School offers FREE membership Fergus Falls Public Schools to K-12 schools in the Frazee-Vergas High School region. To learn more, Hawley High School visit www.tsma.org or Henning Public Schools contact the office. Herman-Norcross School Holdingford High School Minnewaska Area HIgh School Morris Area High School New York Mills High School Osakis Public Schools Rothsay Public Schools West Central Area Schools Meeting registration is required. $20.00 per Person Educators are invited to attend FREE of charge! Teachers, administrators, counselors, school board members ... be our guest! TSMA requests remittance for all reservations notcancelled prior to the event. Phone: 800-654-5773 [email protected] www.tsma.org m Page 5 Minnesota Manufacturers Week Celebrated Across the State Dream It. Do It. Statewide Tour of Manufacturing logs a successful 4th year November 2014 Over 1,500 students from 26 high schools throughout Minnesota participated in Minnesota’s Statewide Tour of Manufacturing on October 23-25, 2014. A total of 85 manufacturers from all corridors of the state, along with three technical colleges, opened their doors for public or “student only” tours to provide an up close look at what manufacturers do and how they do it. (The number of visits from the PUBLIC was not yet available as of press time.) Tour of Manufacturing provides a rare opportunity to see the inner workings of a factory, meet the people who work there, gain insight into the skills, education and training necessary for a career in manufacturing, and learn more about the economic impact of manufacturing. Nearly 800 visits were logged to the Tour of Manufacturing website during Minnesota Manufactures Week. Highlights of the 2014 Minnesota Manufacturers Week include: • Minnesota Governor Dayton issued a proclamation declaring “Manufacturers Week” in Minnesota to highlight the importance of the industry to the state’s economy. • A Manufacturing Breakfast in central Minnesota, featuring the Minnesota DEED Commissioner (Katie Clark Sieben) as keynote speaker, helped bring political attention to the importance of this event. • A Manufacturers’ Appreciation luncheon was hosted by the Southeast Chamber of Commerce, with 90 people taking a tour. • Speeches and videos promoting manufacturing career opportunities were shared at high schools surrounding the tour dates. • 360º Center of Excellence, supported transportation scholarships for “student-only” tours throughout the state. • DreamItDoItmn.com tattoos were supplied to each manufacturer as a giveaway for students to connect with more information about Minnesota manufacturing and career opportunities. • Promotional toolkits were provided by download to all tour hosts via the website. • Radio spots, press releases and newspaper highlights were broadcast throughout the state. • Manufacturers celebrated industry success at association-hosted events in St. Cloud, Winona, Brooklyn Park, Fargo, and more. • A “Made in Winona” series was developed in the Southeast region-featuring a local manufacturer on the front page of their daily newspaper and online. • A career exploration program was launched in the Southeast region with an industry partner discussing the many careers involved with manufacturing, and they promoted the Dream It. Do It. MN resource. • A Manufacturers’ Breakfast in west central Minnesota focused on an impressive new manufacturing education program in a high school setting. Kudos to the TSMA members who hosted a tour this year: Massman Automation (Villard), UMC (Monticello) and Windings (New Ulm). 2014 Statewide Tour of Manufacturing Comments from Teachers I knew we had hit a home run when we arrived back at the high school. Practically all of the students gave me high fives, knuckles and thanks for a great field trip as they left the bus. I think they really appreciated it and I then thought to myself, “This school will not let you down.” ‘Author Unknown’ A huge “Thank You” to all of you folks that made this outstanding education tour possible. This was such a great opportunity for not only our curious, but very eager students to see our local industry in action (real time). Wow! Wow! Many of our CIM (Computer Integrated Manufacturing) students were skeptical prior to this tour, however, the huge look in their eyes told the story when they saw the Pequot Tool & Manufacturing and Truss Worthy operations in action. It was so precious and clearly an eye opener. Thank you, Trent and Mary Ruth, for the guidance. Phone: 800-654-5773 [email protected] www.tsma.org m Page 6 TSMA Seeks Nominees for “2014 Member of the Year” Award November 2014 The TSMA Board of Directors is excited to call for nominees for the TSMA 2014 Member of the Year Award. Please call or email the office with your nomination – nominate your own company or a fellow member. All members-in-good-standing are eligible, including service providers. The award will be issued to a company, not an individual. The selection process will take the following criteria into account. • Regular attendance at TSMA meetings/ events. 2014 M E M B E R TSMA Member of the Year PAST RECIPIENTS 2010 2011 2012 2013 Alexandria Tech & Comm College Innova Industries Inc. Lind-Rite Precision EJ Enterprises • Extra effort to assist TSMA with its goals. Examples: participate on a committee, support workforce development activities, sponsor the golf social, promote the TSMA scholarship program, advertise in the newsletter or directory, sponsor a meeting, host a tour, provide a guest speaker, submit articles for the newsletter, etc. • Effort to promote TSMA to others. Bring a guest to a meeting, submit the names of potential members, share the membership directory, provide a link to the TSMA website, etc. The deadline for nominations is December 1, 2014. The award winner will be acknowledged at the TSMA annual meeting in January 2015. Call or email the office to request a nomination form, or download the form located on the home page at www. tsma.org. Help us acknowledge our deserving members; submit your nomination today! DEED Tour Day Cancelled Regrettably, “Manufacturing Tour Day” scheduled with DEED Commissioner Katie Clark Sieben on October 7, 2014, was largely cancelled. TSMA did proceed with a luncheon meeting in Fergus Falls, with Deputy Commissioner Blake Chaffee filling in as guest speaker, followed by a tour of West Tool & Design. Although tours of Lind-Rite Precision in Osakis, Aagard Group in Alexandria, and Shoremaster in Fergus Falls were cancelled, we want to express appreciation to these companies (along with West Tool & Design) for their willingness to spotlight modern manufacturing for state officials and legislators. TSMA Election Underway TSMA members, check your email for a link to the BALLOT for TSMA’s 2015 Board of Director election. Cast your vote by Noon on Tuesday, November 4, 2104. Ballots were issued via email to the “primary contact” for each member (one ballot per company). Six nominees are listed on the ballot, with four positions up for election. Thank you to all nominees and potential nominees for your interest in serving TriState Manufacturers’Association! Election results will be announced at TSMA’s November 4th general meeting. Phone: 800-654-5773 [email protected] www.tsma.org m Page 7 November 2014 Billboard Cost-Share Increases to 75%! Call the TSMA office to inquire about the Billboard Cost-Share program. The program recently adopted a 75/25 formula, meaning grant funding from West Central Initiative will pay 75% of the cost of a billboard (max of $1,500) that promotes YOUR company and Dream It. Do It. Use billboard advertising to remind people that manufacturing is alive and well in west central Minnesota! Limited funding available; call today. Minnesota Manufacturing Summit Held October 1 A crowd of 135 people attended the recent 2014 MN Manufacturers’ Summit in Bloomington. Thomas Edison’s great grandniece, Sarah Miller Caldicott, shared insights on how Edison used collaboration as a driver of his innovation success and how it can be applied to business today. Building and sustaining a world class manufacturing workforce was the subject of keynote speaker, Dr. Annette Parker, president, South Central College followed by a panel presentation about the opportunities and challenges facing Minnesota manufacturers. Thank you Minnesota Chamber of Commerce for spearheading the annual Summit, held in conjunction with Manufacturers month this year. TSMA Strives for Effective Email Communication Phone: 800-654-5773 “Topic specific” distribution lists are under development in the TSMA database. These can target your special interests or can target specific employees in your company. For example, perhaps you want your Human Resources personnel to receive only information related to HR. They could be marked as “Human Resources” in our database. To the right is a list of the categories we have identified. Let us know who in your company is intersted in what topic. Please know you can change your selection(s) at any time by contacting the TSMA office. [email protected] • • • • • • • • Meeting Announcements Newsletter Government Affairs Workforce Development Sales/Marketing Human Resources Quality & Continuous Improvement Safety/Compliance •Golf Social Please contact Steph Davis (stephd@ runestone.net) to have your name (or that of a fellow employee) added to one or more of the lists above. To date, nonmembers are also encouraged to share their email address. www.tsma.org m Page 8 Modern Manufacturing Learning Lab Coming to Fergus Falls High School TSMA Goals 2014 Phone: 800-654-5773 November 2014 Remarkably, community members in Fergus Falls are less than fifteen percent away from reaching their 3-year goal to raise $350,000 to implement a Modern Manufacturing Learning Lab at Fergus Falls High School. Launched in early 2014, the program raised $300,000 in just a few short months! The new Lab will teach the use of CNC machines, creativity, innovation, and accuracy – all skills that are in demand in manufacturing. The improvement project involves the installation of commercial flooring, wall coating and lighting; improved ventilation; and expanded electric service. New equipment includes: welders, 3D printer, laser engraver, and CNC router, milling, and plasma CAM. Tri-State is pleased to contribute $500 towards this project. Evan Westra, TSMA President, hands Rick Schara a check - both are taskforce members raising money for this project. The TSMA Board of Directors established four goals to guide decision making in 2014: 1.Effective partnerships: Increase TSMA’s effectiveness by having the right conversations with the right people. 2.Growth: Increase the number of companies paying membership and becoming actively involved in TSMA. 3.Workforce Collaboration: Continue to collaborate on innovative projects focused on increasing the number of people interested in careers in manufacturing. 4.Government Relations: Improve legislative advocacy in the manufacturing community. [email protected] www.tsma.org m Page 9 November 2014 November 18, 2014 Educational Program: 9:00 a.m.-4:30 p.m. Networking Reception: 4:30-6:00 p.m. Sheraton Minneapolis West, Minnetonka, MN Learn how the Internet of Things: • Impacts the industrial world • Changes the fundamentals of automation through pervasive sensing • Affects product design Who should attend: • Manufacturers engineers & technicians • Product development engineers & technicians • Manufacturing business and human resource managers • Manufacturing chief technology officers • Manufacturing business owners Rockin’ Transformation With an innovative approach to design and high building standards, W. Gohman Construction recently renovated and added to the Public Works facility in Maple Grove, MN. The result was a stunning transformation that yielded optimal work and storage space. GENERAL CONTRACTING Lea indust rn from ry topi c leade about rs h Interne ow the to is tran f Things sfo manuf rming acturin g! REGISTRATION COST Professional: $95 Student: $30 TO LEARN MORE Visit www.360mn.org Contact Karen White 218-755-2206 [email protected]. An affirmative action, equal opportunity employer and educator. State Launches Initiatives to Encourage Small Business Growth The Minnesota Department of Employment and Economic Development (DEED) has launched three new initiatives that offer assistance to help small businesses in Minnesota expand or improve their operations. DESIGN/BUILD CONSTRUCTION MANAGEMENT wgohman.com Officials said the Greater Minnesota Job Expansion Program, Innovation Voucher Pilot Program and Job Training Incentive Pilot Program will encourage job growth, increase private investments and expand the tax base. Read more.... St. Joseph, MN • 320.363.7781 • [email protected] Phone: 800-654-5773 [email protected] www.tsma.org m Page 10 TSMA Scholarship Program Nov. 14 Deadline Contributed By: Brad Stevens, Relationship Manager Defining Interest Rates Brad Stevens is a Relationship Manager with Alerus Financial, a full service commercial bank serving in your best interest. With over twenty years experience, Brad works closely with business owners to provide advice and financial solutions amongst the ever-changing market cycles. Contact Brad at 651.746.6153 to discuss fresh, innovative financial strategies for your business. Alerus Financial Phone: (952) 417-3753 [email protected] Phone: 800-654-5773 November 2014 Promote TSMA’s scholarship opportunities to your employees and it could be someone you know receiving money to help fund their manufacturing-related careers! www.tsma.org Back in college I had an Economics Professor that declared to my class, “Never try to predict Interest Rates, even though you have a 50% chance of being right, chances are you will always be wrong”. Over the past 35+ years I would say the Professor was right, every time I heard an interest rate prognosticator try his luck, the market proved him wrong. Even recently, in the past year when I heard that interest rates had hit bottom and were headed up, they confounded the “experts” and went down further. As a business owner you should know about interest rates, what they mean and how they work, even if they cannot be predicted. Simply put, interest rates are nothing more than the cost of using money. Banks will pay you to use your money via a savings account interest rate. You get the privilege of paying the bank an interest rate to use their money when you borrow from them. There are essentially two kinds of interest rates, short term and long term. Short term rates are typically any rate that will or can adjust in less than a year. The Prime Rate is one example of a short term rate. The Federal Reserve Discount Rate is also a short term rate. This rate, The Federal Reserve Discount Rate, is the price charged to banks for borrowing from the Federal Reserve to meet daily needs. If the Government wants more stimulus in the market, they will cut this rate which in turn the banks pass on by lowering the Prime Rate to its clients. Any interest rate tied to the Prime Rate will thus move down, allowing for a cheaper cost of funds to the client. If the Fed wants [email protected] the economy to contract, they will raise the discount rate. Any short term borrowing that you have will be priced at a short term rate. Short term rates are then tied to what the Federal Reserve does, essentially. Long term rates are associated with lending for one year or longer. The longer term rates will typically reflect the “Market” predictions of how inflation will have impacted the core principal either invested or borrowed out to the maturity date, whether that is 1, 3, 5, or longer in years. These rates are typically set in the Bond Market, with the core being Treasury Bonds/Bills. Corporate Bonds are typically priced for interest rate purposes at the corresponding maturity plus a risk premium. Your term loans will be based on a core bond rate plus a similar premium. The “Bond Market” thus sets the long term rates. While the Federal Reserve may have some influence in this market by the amount of bonds they issue, it is really the investment market with the expectations they have on the return they want that will, in the end, influence what you have to pay to borrow for that next piece of equipment. While you cannot always predict where interest rates are going, you now have a bit of information on the back ground of rates and where to look for any trends on where they might be going. www.tsma.org m Page 11 November 2014 Highlights from the October Board Meeting The Tri-State Manufacturers’ Association Board of Directors met on October 7, 2014, at West Central Initiative, Fergus Falls, MN. The consent agenda was approved, including September 9, 2014 meeting minutes, September 2014 financial reports, and updates on membership, PMMC, investment strategy, career expos, and holiday party. Discussion was heard regarding the outcomes from Manufacturing Bound. The TSMA Events Committee will advise on whether or not to host a like event in the future. Six nominations were confirmed for the TSMA election ballot. Ballots will be issued electronically in October and tabulated at the November 4th general meeting. Regarding the Billboard Cost-Share program, the board passed a motion accepting the extended deadline of June 30, 2015 and changing the parameters from a 50/50 costshare offer to 75/25 cost-share, pending approval from the granting agency, West Central Initiative. Kashmark reported on funds remaining re: the Robotics Gear Up Grant. TSMA is attempting to collaborate with LCSC to combine remaining grant funds and offer additional LEGO League workshops, but finding an available instructor has proved challenging. Discussion to continue. In an effort to further expand secondary school involvement with manufacturing, the board passed a motion authorizing staff time to develop an all-inclusive contact list for K-12 superintendents, principals, and career counselors in the TSMA service region and commence with monthly communication from TSMA. The board approved grant funding of $1,000 each for Rothsay Schools to purchase LEGO kits and for general expenses for the QWERTY robotics team from Detroit Lakes. Discussion was heard regarding nominees for TSMA 2014 Member of the Year. Suggested programs and tours were discussed for upcoming TSMA general meetings. With regard to expanding partnerships, Enterprise Minnesota will be invited to the November board meeting. The next TSMA board meeting is scheduled at 3:00 PM on November 4, 2014, at the Alexandria High School in conjunction with the general meeting. Mark Your Calendar TSMA Holiday Social TSMA Annual Meeting Elbow Lake Fergus Falls Tuesday, December 16 Tuesday, January 6 Join your TSMA friends at the Knotty Pine for the annual Holiday Social Mark you calendars for the TSMA Annual Meeting 5:00 p.m. Social 6:00 p.m. Dinner Dinner/Meeting - Bigwood Event Center Tour - PAYDAC PLASTICS, Inc. Final details pending Click here for flyer and to register. Phone: 800-654-5773 [email protected] www.tsma.org m Page 12 November 2014 Meeting Update: $100 Cash New Member Corner A welcome is extended to the newest member of Tri-tate Manufacturers’ Association... Welcome! Drawing, and Thank You Remember to turn in your business card at each Tri-State meeting for a chance to win $100 at a future meeting! One business card will be drawn from “the hat” each month; the person named on the card must be present to win. At the October TSMA meeting the name of Elroy Vesta, EJ Enterprises, was drawn. Elroy was present to win the $100 prize. DMK Intellectual Property Law PLLC 18281 Minnetonka Blvd, Suite F Wayzata, MN 55391 Deirdre Kvale, Patent Attorney [email protected] www.dmkiplaw.com 952-476-4005 Thank You Legal services for intellectual property law, patents and trademarks. Blake Chaffee, Deputy Commissioner at MN Department of Employment and Economic Development for stepping in to update TSMA membership on the state of the economy especially in regards to manufacturing at the October 7 meeting. Career Opportunities in Manufacturing Thank you West Tool & Design for hosting a tour of your facility! http://youtu.be/lSSshHHJCxM Productive Alternatives Your Source of SUB-CONTRACT LABOR Manufacturers Directory and Database TSMA Members save 20%! SILK SCREENING •Quality silk screening on a variety of materials •Factory direct pricing on decals, real Purchase an online Manufacturing Database from MNI and save 20%! This offer is available to members of AMFA, CMMA, TSMA and the Brainerd Manufacturing Alliance when you order online using the link below. www.manufacturersnews.com FREE search offer! The MMA office has access to database information in the five-state area and members are encouraged to request a “basic search” free of charge. Examples of research that typically takes just a few minutes of time: address or contact name for a particular company; list of companies in a certain city, county or state; capability search by SIC or NAICS code; and more. Call to inquire! Phone: 800-654-5773 for your production needs MACHINE WORK Drilling, riveting, blister packing, heat sealing, shrink wrapping... estate signs, magnetic and custom signs for industrial, municipal and commercial use WOODWORKING •Complete start to finish or your product components •Stakes - hardwood or softwood WHY PRODUCTIVE ALTERNATIVES, INC? RELIABILITY ~Quality products on time SAVE MONEY ~Pay by the piece ~Pay only for items completed to your satisfaction ~Don't pay for freight [email protected] ASSEMBLY •Simple and Complex •Small and Large •We assemble to your specifications PACKING •Blister packing •Heat sealing •Shrink wrapping •Other types of packing BULK MAILINGS We collate, fold, insert and label millions of items/year. Call for a free estimate! Steve Lorshbough Productive Alternatives 1205 N Tower Road Fergus Falls MN 56537 Ph. 800-477-7246 Fax 218-736-2541 www.tsma.org m Page 13 November 2014 A cost effective way to reach a broad manufacturing audience. Promote your product or service to AMFA, CMMA and TSMA for one annual fee. To learn more, contact Sandy Kashmark at 800-654-5773 or [email protected] - CNC Milling - CNC Turning - CNC Router (60” x 144”) - Manual Machining (Vertical, Horizontal) - CNC Forming - TIG/MIG Welding - Waterjet Cutting - Fabrication - Prototyping - Short and Long Runs - Short Lead Times We are able to process virtually any kind of material! 417 Co. Hwy 88 South Rothsay, MN 56579 Phone:(218)867-2244 / Fax:(218)867-2280 E-mail: [email protected] www.galaxy-enterprises.com Visit www.tsma.org Industrial Machinery Movers Would you like your company featured as Company of the Month in the Network News? Contact the TSMA office at 800-654-5773 or [email protected] • Moving all types of industrial equipment • One piece or Entire Plant • Fully Insured • Air Ride Tractors, Trailers • Presses ~ Brakes ~Shears • CNC Machining Centers Cell: 701-899-0543 • Ph: 701-642-9515 Wahpeton, ND Phone: 800-654-5773 All it takes is about an hour or so of your time. The interview can be done in the comfort of your office or remotely over the telephone. Call Steph to schedule your company as Company of the Month. [email protected] www.tsma.org m Page 14 The “Legislator Connection” November 2014 A program called “Legislator Connection” encourages manufacturing members to use TSMA staff time to coordinate a visit from a local senator or representative. We want to make it easy for you to develop and nurture a relationship with your legislators. Feedback suggests that plant tours are incredibly effective in changing outdated perceptions and increasing awareness of the high skill, high wage, high technology careers options the industry has to offer. You get one-on-one time to express concerns, ask questions, and express appreciation for a job well done. Call or email the office today to utilize the Legislator Connection! Senator Klobuchar Visits ITW Heartland Minnesota Home to Innovative Business and Cool Products Minnesota is known as the best place to live, work and play. And it’s the 10th most innovative state in the U.S., according to 2014 rankings by Bloomberg. Minnesota is home to innovative manufacturing companies, suppliers and products. And cool products can be found in the Made in Minnesota Directory, a database launched by DEED in 2013 with thousands of diverse products. Here’s a small sample: Jaeckel Inc. New mechanical action pipe organs are made at Jaeckel Inc. in Duluth. Dan Jaeckel is considered one of the most respected organ builders in the world. His organs have been sold nationwide and internationally. Productive Alternatives Inc. Ice fishing and other products are made by Productive Alternatives Inc., a non-profit agency in Fergus Falls. The products are made by persons with disabilities. (Is a TSMA Member) Clay Squared to Infinity. Handmade tile and polymer clay art are produced by a husband and wife team. Their art has been awarded the Best of the Twin Cities - 2014 Midwest Home - Best Assist for Period Purists and Best of 2014 Customer Satisfaction on Houzz. The Company, Clay Squared to Infinity, is in Minneapolis. Phone: 800-654-5773 [email protected] Indian Island Winery. 100 percent Minnesota grown wine production is the focus of the Indian Island Winery, which is family-owned and operated. And the quality of the wine stands out. The winery recently entered the 2014 Finger Lakes International Wine competition and garnered silver and bronze medals for several of their wines. The winery also offers Happy Hour Yoga. RapidPure Inc. A water filtration system contained in a bottle is made by RapidPure Inc., creating clean drinking water from water that is unsafe. It is especially useful for camping, traveling and emergencies. All these companies can be found in the Made in Minnesota Directory. The directory makes it easy for companies to find – and be found – by home state suppliers. Using the directory helps manufacturers by saving time, money on transportation costs and other long-distance expenses. In addition, manufacturers can meet their other sourcing goals such as finding organic supplies or purchasing from a specific county of the state. The directory has nearly 900 manufacturers and suppliers listed and is free to use and be listed. Try it now and see what cool products you can find! For more information about the Made in Minnesota Directory, contact Magda Olson at 651-258-7183. www.tsma.org m Page 15 ADOPT‐A‐SCHOOL GUIDE A Toolkit for Employers November 2014 Imagine a partnership that is a win-win scenario one that offers high potential to show a long term return on your investment, a future talent pool for your industry, and relationships that pave the way to give back to the community. TSMA Website Offers FREE Job Posting & Classified Ad Opportunities The TSMA website has a page for posting current job openings and posting classified ads. Whether you are trying to find an employee, looking for a job, or trying to sell excess equipment, start on the TSMA website. Visit: www.tsma.org Get your copy of the “Adopt a School Guide: A Toolkit for Employers” today. Available in hard copy from the TSMA office or as an electronic link (PDF) at www.tsma.org, the 16-page guide provides a wealth of information about developing a relationship with your local school. Manufacturers - take the first step today: get your hands on a copy of the all new Adopt-A-School Guide! Intelligent. Just Like You. Whether you need a new system, repairs or replacement parts, you can depend on flexible solutions from American Time. • Wireless System Clocks • Wired System Clocks • Power over Ethernet Clocks • Wi-Fi Clocks – NEW! • Battery Clocks Personalized with your logo! FREE Call 800-328-8996 Click atsclock.com Fax 800-789-1882 TSMA14 Phone: 800-654-5773 [email protected] www.tsma.org m Page 16 November 2014 TSMA Board of Directors TSMA Standing Committees President: Evan Westra West Tool & Design Fergus Falls MN 218-739-4990 [email protected] Directors: John Hansen Bell State Bank & Trust Fergus Falls 218-998-5600 [email protected] Tri-State members are invited to join a committee at any point throughout the year. Contact the TSMA office or the committee chair directly. Vice President: Tyler Wirth Spartan Staffing Alexandria MN 320-762-2001 [email protected] Secretary/Treasurer: Bob Grove Cosmos Enterprises Elbow Lake MN 218-685-4403 [email protected] Tom Mastellar Blackhawk Industrial St. Cloud MN 320-253-1020 Special Events Committee, Chair: Tom Mastellar John Hansen, Dan Kotek, Marilyne Morisette, Kathy Pesta, Director Emeritus Clint Grove, retired Elbow Lake MN 218-685-5230 [email protected] Kevin Schutz OECS, Inc. Golden Valley MN 763-417-9599 [email protected] Elroy Vesta EJ Enterprises Fergus Falls MN 218-739-9677 [email protected] Membership Committee, Chair: Mike Westergard Elroy Vesta, Gerry Nelson Workforce Committee, Chair: Bob Grove Evan Westra, Tyler Wirth Government Relations Committee, Chair: Kevin Schutz Ed Bolas, Brent Cochran TSMA Membership Dues Mike Westergard StoneL Fergus Falls MN 218-739-5774 [email protected] The Network News is edited and published at the Midwest Manufacturers' Association office located at 117 Central Avenue North, PO Box 150, Elbow Lake, MN 56531. MMA/ TSMA phone 218-685-5356. Fax 218-685-5397. Toll-free 800-654-5773. Email: [email protected]. Office hours are 8:30 AM to 5:00 PM Monday through Friday. However, messages can be left on the answering machine at any time. TSMA Core Values The TSMA Membership Dues Structure is identical for manufacturing and associate members. Dues are based on number of employees. No. of Employees Annual Dues 1 person shop.............. $100 2to5.......................... $150 6 to 15........................ $200 16to30........................ $225 31to50........................ $275 51to100...................... $300 101to200...................... $350 201ormore.................... $375 Gov/Edu........................... $ 225 TSMA Mission Statement Tri-State Manufacturers’ Association assists manufacturing related companies by providing advocacy, education, networking, and programs to enhance the success of members and their communities. 1. Tri-State Manufacturers' Association is committed to developing people and companies by providing opportunities for members to acquire industry relevant knowledge or skills. 2. Integrity and trust are guiding principals for Tri-State Manufacturers' Association. 3. Tri-State Manufacturers' Association believes that open, accurate and timely communication is important to accomplishing its mission. Phone: 800-654-5773 [email protected] Membership Plaques are presented to current members at TSMA networking events. Several TSMA members collaborated with the Machine Technology students at North Dakota State College of Science to produce the plaques. www.tsma.org

© Copyright 2026