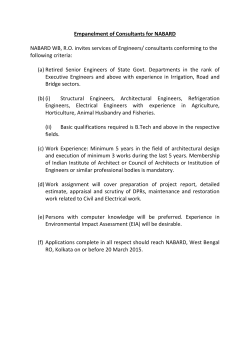

ORBITFORM SOLUTIONS LAB IT ALL STARTS WITH THE CUSTOMER’S PART

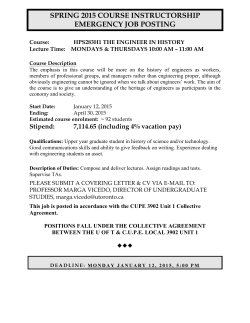

MADE IN THE USA ASSEMBLY SOLUTIONS LAB IT ALL STARTS WITH THE CUSTOMER’S PART ORBITFORM SOLUTIONS LAB At Orbitform it all starts with the customer’s part in our Assembly Solutions Lab. Our application engineers know the best way to optimize an assembly process is by assembling your sample parts. Product engineers receive invaluable feedback, suggestions for part features, and a more efficient and cost effective process. What sets us apart is our unbiased approach as you’re not restricted to a single product line. Orbitform offers a range of assembly processes including: Orbital, Radial, Impact, Hot Upset, Roller Forming, Pressing, and Projection and Resistance welding. ORBITAL FLARING When spot-welding failed, an automotive parts supplier contacted Orbitform to attach a hardened steel gear to a metal stamping. Orbitform engineers suggested adding an extrusion and orbitally flaring the extruded lip over the gear, eliminating the need for a costly fastener. Extrusion Peen Gear 1600 Executive Dr. Jackson, MI 49203 - (800) 957-4838 - www.orbitform.com ASSEMBLY EQUIPMENT SOLUTIONS FOR MANUFACTURING SINCE 1984 HOT UPSET An equipment manufacture was welding a hardened steel rod into a hex hole to prevent rotation, but welding annealed the rod and vibration caused some joints to fail. Orbital forming did not flow enough material to prevent rotation, so application engineers applied Hot Upset, creating a high torque joint with 99% hole-fill at a lower temperature than welding. ROLLER FORMING An electrical sensor manufacture was multi-point crimping a metal cap over a heat sensor. Stress risers at the crimp points allowed moisture inside, damaging components. Orbitform engineers’ Roller Formed the cap for a tighter seal with 360 degrees of retention. SEND US YOUR SAMPLE PARTS FOR ASSEMBLY ANALYSIS ORBITAL STAKING In another example, a round threaded steel fastener needed to be secured into a hex hole through a 1/8” wall aluminum stamping. The fastener also needed to hold torque while a nut was applied. Projection welding was not an option with dissimilar metals. Orbitform engineers developed a cold headed, shouldered fastener and hollow peen to orbitally ring‑stake the fastener’s shoulder, locking it into place. Peen Shoulder Threaded Fastener What can Orbitform’s Assembly Solutions Lab do for you? Send us your sample parts and let us find the assembly process that best meets your needs… 1600 Executive Dr. Jackson, MI 49203 - (800) 957-4838 - www.orbitform.com

© Copyright 2026