Delivering Efficiency: Streamlining Pick-Up and Delivery in the Post & Parcel Industry

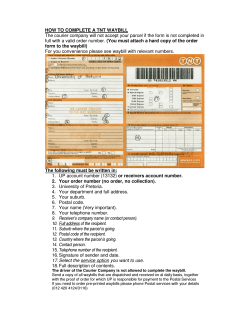

White paper Delivering Efficiency: Streamlining Pick-Up and Delivery in the Post & Parcel Industry Introduction In today’s fast-paced post and parcel industry, streamlined efficiency is more important than ever. Often times, however, the determining factors are out of our control. Many of the most technologically-advanced delivery companies in the world still pick up a relatively high percentage of their items without prior knowledge of the destination or any other delivery element prior to taking physical control of the item. For example, what portion of your business is a surprise? How do these surprises impact your downstream processes? How much does it cost you when an item cannot be delivered the first time (or at all) and must be rehandled, redelivered or returned to sender? First, let’s define a “surprise.” In this use, it is an item that walks into your retail location or is picked up at a scheduled or regular pick-up point without the details of the shipment or delivery available prior to the pickup. Some of our most advanced customers don’t know the answer to this question prior to being asked. Do you? When challenged, some of the most advanced companies in the world found “surprises” like these are accounting for as much as 10-25 percent of the items they are picking up. That is as much as 25 percent of their business they don’t know about in advance – meaning they can’t plan for downstream processes, in turn eliminating much (if any) chance to do dynamic network optimization or downstream labor planning. That also means as much as 25 percent of their business also requires someone to sit in front of a computer to manually enter the shipping details, including the delivery address, which they tell us can take in excess of one minute per package – ultimately costing millions of dollars each year. If they want any chance of advanced notice on the shipment and true tracking from the point of pickup, it entails having their most expensive resource, the courier, enter the data on their mobile computer. Our customers have found that these methods are not only time consuming, but very error prone as well. And, due to decreasing work forces and overall increased productivity issues, delays and other shipping errors are further decreasing customer satisfaction. According to a 2009 Gallup Poll, the U.S. postal industry alone has lost $8 billion since 2007.1 In order to be successful in such challenging times, industry leaders must find ways to both increase revenue and reduce costs. To mitigate these issues, post and parcel industry operators are actively pursuing new technologies to help enhance profitability, while also increasing visibility and planning capabilities through the elimination of errors.2 New technology solutions may hold the key to solving this issue. Eliminating Manual Entry, Increasing Overall Visibility Today’s post and parcel organizations have been drastically affected in recent years by rising costs and shifting requirements – meaning doing business in the global economy is creating new challenges for companies with even the biggest technology budgets. More than ever, companies are looking to new technology solutions to offer a better visibility into their daily operations, helping to avoid errors before they start. As previously mentioned, our customers estimate that in today’s post and parcel systems nearly 25 percent of items aren’t visible in company track-and-trace systems upon customer pick-up, causing these items to be manually entered later at some point along the process. The human error associated with manual entry alone is high, but companies also must take into account that these manually-entered packages become an unwelcomed surprise to sortation workers when they arrive at the sorting center. With only a few hours between the items’ pick up and the sorting process, there is little time to manually enter these items into the track-and-trace system with any advance notice for downstream process workers. Not to mention that the further into the process that the item gets from its origin, the higher the level of complexity and costs related to the research or customer service necessary to rectify issues. An obvious statement, but worth saying is that it is easiest to correct issues standing in front of the customer versus remotely solving the problem later. Misrouting errors can also easily occur from manual entry. In the postal industry, many current automated processing machines read addresses from the bottom up, searching for a delivery address last. If machines can’t read each individual line, or can’t accurately read the way the address was written, the mail can be delayed or misrouted. Additionally, added information, such as an attention line, can further confuse and misdirect mail. Essentially, in current processes, it’s undeniably easy for pieces to get deep into the delivery network before any problem with the address is recognized, often making it all the way to delivery before the error is noticed. This causes the item to be re-handled – potentially as far back as the items’ origin, and the costs associated with these re-deliveries can be staggering. A technology that could verify the validity of addresses from the point-of-pickup could easily correct these simple errors before they happen, allowing for increased visibility, better efficiency and increased overall ROI. 1 Jones, Jeffrey. “Americans Advocate Reduced Services to Help Postal Service, Gallup Poll.” Feb. 16, 2009. http://ow.ly/2XYZM 2 Danner, Phil. “Increasing revenue and cutting costs: Staying ahead in the postal industry.” Nov. 1, 2008. http://ow.ly/2XZ0y 2 For example, Figure 1 showcases how manual entry could sideline a fleet of drivers in a single day. As Figure 1 clearly showcases, simply eliminating the time necessary to input a few items requiring manual entry per day can equate to hundreds of lost hours saved day for an entire fleet. This otherwise lost time can equate to delivery delays, lost revenue, customer dissatisfaction or overall losses, not to mention artificially increased labor costs. New technologies that offer to extract and verify address data would save not only the additional labor expenses associated with the data in Figure 1, but would help to eliminate bottlenecks at sorting centers currently necessary to handles these items. Additionally this would enable other process, such as network planning, to work from much more accurate information received hours in advance of current processes. To summarize, a solution that would quickly and accurately allow data entry at the point-of-pickup would allow companies to optimize downstream logistics, displaying in real-time what items are being entered into the system and where they will need to be delivered. This offers total transparency from pick up to delivery. use some sort of address verification, but these systems only work if the address is entered and verified before pick-up. With rising fuel costs and smaller workforces, “undeliverable as addressed” has become one of the biggest proficiency issues in today’s postal industry – and certainly one of the most costly. As previously outlined, many items brought into delivery systems aren’t addressed correctly, yet it’s often hard to catch these errors until the address is either verified at the sortation center, or until the driver realizes there is an error upon delivery. This creates not only a significant delay to the shipper, but the added expense of correcting the delivery error. A mobile solution that would provide the same proven address verification used in current sortation operations would help with this phenomenon. Unlike manual entry and paper-based processes, a mobile verification solution could automate the extraction process, offering a cleansing and correction of any data errors at the collection point, eliminating issues before they entered the network. This could virtually eliminate the “undeliverable as addressed” problem on every item processed, offering an incredible increase in accuracy in an easy-to-implement solution with minimal process impact. Undermining the Undeliverable Industry research suggests a large national parcel operator can easily face thousands of dollars per year in delivery re-attempts, with each undeliverable parcels costing up to $10 process and resend.3 Many post and parcel companies have systems that Figure 1: Cost of Manual Entry Company Drivers 1,000 5,000 10,000 Average Average Parcels/Driver/Day Time/Parcel for Manual Entry for Manual Entry 10 6 2 60 seconds 60 seconds 60 seconds Total Time/Driver/Day for Manual Entry 10 minutes 6 minutes 2 minutes Total Time/Fleet/Day 166 hrs 500 hrs 333 hrs Average Hourly Full-time equivalent cost $50USD $50USD $50USD Estimated Savings Per Fleet 166 hrs x $50 = $8,300/day $8,300 x 250 days = $2M/yr 500 hrs. X $50 = $25,000/day $25,000 x 250 days = $6.3M/yr 333 hrs x $50 = $16,650/day $16,650 x 250 days = $4.2M/yr Fill in Your Own Figures: 3 Brown, Kevin. How Today’s Intelligent Postal Technologies can Benefit Best-in-Class Merchants.” April 2010. http://ow.ly/2XYUH 3 Increasing Customer Satisfaction Customer demand for increased delivery performance is at an all time high. The increased demand for instant and accurate delivery status and customer information is driving a dire need to ensure shipment integrity in the post and parcel supply chain. In fact, the increase in customer demands, including shorter cycle times or higher on-time delivery performances were noted as a top pressure by nearly 35 percent of “Best-in-Class” respondents in a recent study by Aberdeen Group on transportation organizations.4 Delayed or undeliverable shipments are considered unacceptable by shippers and receivers, making customer service one of the most important factors in delivery operations. Additionally, because customers and businesses can increasingly source more and more products on the Internet, post and parcel operators are looking to further maintain their businesses through satisfied repeat customers. As a result of rising fuel prices and other economic factors that rise overall operational costs, delivery organizations must operate as efficiently as possible to avoid further decreased profits. This directly ties into customer satisfaction; with customers already adjusting to rising costs of shipping, they will have less tolerance for errors, and with consumer and brand loyalty decreasing in order to find the lowest overall price, unhappy customers will quickly move their business elsewhere. The ability for a mobile solution to immediately make shipments visible to not only the delivery organization, but to the shipper would help to alleviate this pressure. Customers would know the status of all items shipped from the moment they are picked up by the driver. The same applies to the receiver. They are able to track all items to make sure they will be delivered on time from the moment they leave the sender, which gives them more confidence that their package will be sent or delivered on time, without delays. In the age of increased e-commerce purchases, this is extremely important to maintain customer satisfaction. Shippers realize that their delivery company is as much a part of their customer perception of the service as their own internal processes. Failures, no matter whose fault, impact that perception and ultimately impact the shipper’s relationship with the delivery company. Eliminating unnecessary errors and delays will become more and more vital as technologies and consumer shipping needs increase. In order to improve in this area, companies are increasingly looking to new mobile technologies to help increase revenue and reduce errors to maintain customer loyalty. A New Solution One new technology advancement delivers an overall cost reduction, as well as reduction in errors, in a streamlined, costeffective way: VERDEX, a revolutionary new solution from Intermec Technologies. Nearly eliminating all downstream visibility issues and undeliverable address data, Intermec’s VERDEX is a real-time solution for enhanced data collection that helps to further the delivery process evolution by: • Providing instant, accurate address verification from the point of pick-up • Virtually eliminating all address related errors to offer delivery organizations efficiency • Easily integrating into existing processes with minimal user intervention • Offering unprecedented time savings, improving customer service satisfaction As showcased in Figure 2, VERDEX adds a proficiency not possible with current processes. This new solution not only helps organizations run more efficiently, but virtually eliminates all address related errors while further improving customer service and overall satisfaction. Figure 2 (Manual Entry) (Entry into alpha numeric keypad) (VERDEX) 4 Heaney, Bob. “Internal Transportation: Optimize Cost and Service in a Global Market.” Aberdeen Group Report. July 2010. 4 How it Works With current systems relying on manual entry or choke point processes that capture items for introduction into the network flow, VERDEX offers a type of address verification for the mobile postal worker never before found on a handheld device. The name VERDEX is a combination of “VER” and “DEX” from “verification” and “data extraction.” Compatible only with Intermec’s CN50 and CN3 mobile computers (both operating Window’s Mobile 6.1), VERDEX is able to virtually eliminate current problems in the post and parcel industry worldwide. After capturing an image using a handheld scanner, such as a shipping label, VERDEX performs SmartMatch™ verification against a custom or commercial database of known information, in this case, addresses. After SmartMatch™ verification, the image goes through a cleansing process to validate and correct address information or supply back a corrected address, preventing common shipping errors. Through VERDEX’s SmartMatch™ verification and cleansing process, mistakes, such as listing “street” instead of “road,” spelling a city or street name incorrectly, including any number of address abbreviations, are automatically corrected, ensuring proper delivery. VERDEX easily integrates into line-of-business applications and is currently the only solution in the marketplace to provide context aware data collection at the point of work. Conclusion As the post and parcel industry continues to rely upon more sophisticated processes to help eliminate costly issues, the demand for automated mobile solution and data extraction capabilities is at an all time high. Mobile technology must be utilized in the future to help tackle the costly and advancementbarring issues faced in today’s post and parcel landscape. New solutions, such as VERDEX, offer a complete, error-reducing solution at the point-of-pick up. The postal workforce will find increased efficiency and productivity, eliminating some of the industry’s most troublesome, costly and advancement barring issues worldwide – before they even enter the network. About Intermec Intermec’s innovation dates back for more than 40 years, having successfully integrated hundreds of thousands of solutions into demanding fields around the world. VERDEX was developed in partnership with RAF Technology, Inc., a world-wide leader in advanced pattern and image recognition, intelligent information extraction and data verification solutions. VERDEX utilizes commercial or custom databases provided and maintained by RAF, allowing precise information to pass automatically from the package to pickup and delivery systems. Intermec Inc. (NYSE:IN) develops and integrates products, services and technologies that identify, track and manage supply chain assets and information. Core technologies include rugged mobile computing and data collection systems, bar code printers, label media, and RFID. The company’s products and services are used by customers in many industries worldwide to improve the productivity, quality and responsiveness of business operations. For more information about Intermec, visit www.intermec.com or call 800-347-2636. 5 North America Corporate Headquarters 6001 36th Avenue West Everett, Washington 98203 Phone: (425) 348-2600 Fax: (425) 355-9551 North Latin America Headquarters Office Mexico Phone: +52 55 52-41-48-00 Fax: +52 55 52-11-81-21 South Latin America Headquarters Office Brazil Phone: +55 11 5502.6770 Fax: +55 11 5502.6780 Europe/Middle East & Africa Headquarters Office Reading, United Kingdom Phone: +44 118 923 0800 Fax: +44 118 923 0801 Asia Pacific Headquarters Office Singapore Phone: +65 6303 2100 Fax: +65 6303 2199 Internet www.intermec.com Worldwide Locations: www.intermec.com/locations Sales Toll Free NA: (800) 934-3163 Toll in NA: (425) 348-2726 Freephone ROW: 00 800 4488 8844 Toll ROW: +44 134 435 0296 Media Sales Phone: (513) 874-5882 Customer Service and Support Toll Free NA: (800) 755-5505 Toll in NA: (425) 356-1799 OEM Sales Phone: (425) 348-2762 Copyright © 2010 Intermec Technologies Corporation. All rights reserved. Intermec is a registered trademark of Intermec Technologies Corporation. All other trademarks are the property of their respective owners. Printed in the U.S.A. 612095-01A 11/10 In a continuing effort to improve our products, Intermec Technologies Corporation reserves the right to change specifications and features without prior notice.

© Copyright 2026