A novel method to realize InGaN self-assembled

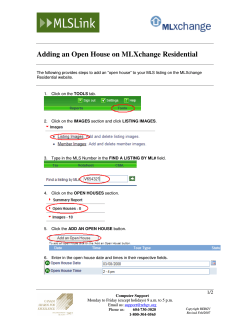

Materials Letters 57 (2003) 4218 – 4221 www.elsevier.com/locate/matlet A novel method to realize InGaN self-assembled quantum dots by metalorganic chemical vapor deposition Liang-Wen Ji a,*, Yan-Kuin Su a, Shoou-Jinn Chang a, Liang-Wen Wu a,b, Te-Hua Fang c, Qi-Kun Xue d, Wei-Chi Lai a, Yu-Zung Chiou a a Institute of Microelectronics and Department of Electrical Engineering, National Cheng Kung University, Tainan 701, Taiwan, ROC b South Epitaxy Corporation, Hsin-Shi 744, Taiwan, ROC c Department of Mechanical Engineering, Southern Taiwan University of Technology, Yong-Kan 710, Taiwan, ROC d Institute of Physics, Chinese Academy of Science, Beijing 100080, PR China Received 19 August 2002; received in revised form 5 March 2003; accepted 16 March 2003 Abstract We report the use of an interrupted growth method in metalorganic chemical vapor deposition (MOCVD) to control the growth of InGaN layers and to grow nanoscale InGaN self-assembled quantum dots (QDs). With a 12-s growth interrupt, we successfully formed InGaN QDs with a typical lateral size of 25 nm and an average height of 4.1 nm. The QDs density is about 2 1010 cm 2. Strong photoluminescence (PL) emission of InGaN nanostructure was observed at a room temperature with a full-width-half-maximum (FWHM) of about 92 meV. These results suggest that such QDs are potentially useful in nitride-based optoelectronic devices. D 2003 Elsevier Science B.V. All rights reserved. Keywords: InGaN; Quantum dot; Atomic force microscopy; PL; FWHM III –V nitride semiconductor materials have a wurtzite crystal structure and a direct energy band gap. At room temperature, the band gap energy of AlInGaN varies from 1.95 to 6.2 eV depending on its composition. Therefore, III – V nitride semiconductors are particularly useful for light-emitting devices in the short wavelength region [1 –3]. Indeed, III – V nitridebased blue and green high-brightness light-emitting diodes (LEDs) made from InGaN/GaN quantum wells (QWs) structures are now commercially available with output power larger than 2.5 mW at 20 mA, * Corresponding author. i.e., external quantum efficiency >10%. Such a performance is quite amazing considering the high 108 – 1010 cm 2 dislocation density in these LEDs [4]. There is strong evidence to support that InGaN alloy inhomogeneities play a key role in the high efficiency of nitride based LEDs grown on sapphire [5 –7]. It has been proposed that nanoscale indium composition fluctuation due to InGaN phase separation results in the formation of indium-rich clusters, which act as quantum dots (QDs) [5 –7]. Hence, the InGaN system acts as an extremely sophisticated quantum capture system, in In(Ga)N QDs, and the charge carriers are deeply localized so as to hinder their migration toward non-radiative defects (dislocations) [7,8]. Therefore, 0167-577X/03/$ - see front matter D 2003 Elsevier Science B.V. All rights reserved. doi:10.1016/S0167-577X(03)00293-3 L.-W. Ji et al. / Materials Letters 57 (2003) 4218–4221 high luminescence efficiency could be expected if the density of QDs is much higher than that of dislocations. QD structures are being intensively investigated not only for device applications but also for studying fundamental physics. It has been shown that nitride QDs can be self-organized using the strain-induced Stranki– Krastanov (S –K) growth mode [8– 10]. Another way to form nitride QDs is to take advantage of surfactants or anti-surfactants, which are often used to change the surface free energy of epilayers [11 – 14]. It had been reported that nitride-based QDs could be formed by using Si as the anti-surfactant [11– 13]. Self-assembled nitride QDs had already been fabricated by molecular-beam epitaxy (MBE) in InGaN/ GaN system [8,10] using S –K growth mode. Recently, Tachibana et al. [9] reported the growth of InGaN/ GaN QDs by metalorganic chemical vapor deposition (MOCVD) without using any surfactant. However, it remains uncertain if the formation of QDs was due to strain-induced mode or phase separation since small three-dimensional (3D) InGaN islands were found after the deposition of up to 20 monolayers (MLs) of InGaN [10]. In this letter, we report an approach to grow InGaN QDs using a novel method in a commercial MOCVD reactor (EMCORE D180). An interrupted growth method was proposed to grow selfassembled InGaN QDs without the use of surfactants or anti-surfactants. Atomic force microscopic (AFM, Shimmadzu SPM-9500JZ) images reveal that InGaN self-assembled QDs were successfully obtained by using interrupted growth method, and their dimensions were small enough to expect zero-dimensional, quantum effects. The optical properties of such InGaN QDs are studied with photoluminescence (PL) results measured at room temperature. All InGaN QD samples used in this study were grown on (0001)-oriented sapphire (Al2O3) substrates in a vertical low-pressure (MOCVD) reactor with a high-speed rotation disk [15 –26]. The gallium, indium and nitrogen sources were trimethylgallium (TMGa), trimethylindium (TMIn) and ammonia (NH3), respectively. After a 30-nm-thick low-temperature GaN nucleation layer was deposited onto the sapphire substrate at 500 jC, the temperature was raised to 1000 jC to grow a 2-Am-thick undoped GaN buffer layer with a growth rate of 2 Am/h. During the growth of GaN buffer layer, the flow rate of TMGa was kept at 88 Amol/min while the flow rate of H2 4219 carrier gas was kept at 10 l/min. The growth temperature was then reduced to 730 jC to grow InGaN QDs. During the growth of InGaN QDs, the flow rates of TMGa and TMIn were kept at 10 and 35 Amol/min, respectively. The carrier gas was switched to N2 and we fixed the N2 carrier gas flow rate at 20 l/min. According to our calibration, the average indium composition in the InxGa1 xN layer should be around x = 0.3. Knowing the lattice mismatch between GaN and InN equals 11%, the mismatch between In0.3 Ga0.7N and the underneath GaN buffer should be around 3.3% (Da/a = 11% 0.3 = 3.3%). Previously, Grandjean and Massies [27] reported that only 3 MLs could be grown layer by layer before islanding when InxGa1 xN was deposited on top of the GaN buffer. In our experiment, the growth rate of the InGaN layer is estimated to be 0.04 nm/s. Here, an interrupted growth method was employed during the deposition of InGaN. We first deposited a thin 4.5 MLs of InGaN on top of the GaN buffer. We then stopped the growth from 12 s. After growth stop, another 4.5 MLs of InGaN was again deposited so as to achieve an InGaN layer with a total thickness of about 9.0 MLs. For comparison, samples without the InGaN layer were also prepared. The surface morphologies of these samples were then characterized as ex situ by an AFM system with a sharpened Si3N4 tip at room temperature. Photoluminescence (PL) was also used to study the optical properties of these samples. During PL measurement, a He –Cd laser was used as the excitation source. The collected luminescence signal was dispersed by a monochromator, and detected by a cooled charge-coupled device (CCD) camera also at room temperature. Fig. 1a and b shows AFM images of the undoped GaN buffer layer and the InGaN QDs, respectively. As shown in Fig. 1a, it can be seen that the surface morphology of the GaN buffer layer (i.e., without InGaN layer) is very smooth. In contrast, a rough surface with the formation of QDs was clearly observed when InGaN was deposited on top of the GaN with growth stop, as shown in Fig. 1b. From the AFM picture, the diameter of QDs is estimated to be in the range of 20– 38 nm, with an average height of 4.1 nm. In addition, the density of QDs is estimated to be 2 1010 cm 2. It is known that clusters grow primarily in two ways: ripening and coalescence. An ensemble of clusters on a surface may undergo a 4220 L.-W. Ji et al. / Materials Letters 57 (2003) 4218–4221 Fig. 1. AFM images of (a) undoped GaN buffer layer, and selfassembled QDs formed by the deposition (b) at 9 MLs. ripening process with mass transport from smaller cluster to larger cluster by atomic surface diffusion. In fact, ripening is a process where larger clusters grow gradually at the expense of smaller clusters. The total surface energy of a system is decreased when small particles combine to form larger clusters with no loss of mass [28]. In our experiment, we first deposited 4.5 MLs of InGaN on top of GaN buffer and then stopped the growth of InGaN for 12 s at 730 jC. Since the critical thickness is only 3 MLs for In0.3Ga0.7N, the initial growth of 4.5 MLs of InGaN should already relax to form small clusters according to strain-induced S– K growth mode. Generally speaking, the strained energy of 3D islands is lower than that of the wetting layer. Thus, if we employ interrupted growth method at a reasonable temperature, small clusters should have sufficient time to combine with each other so as to from large cluster (i.e. 3D islands) by atomic surface diffusion. After growth interrupt, the total surface energy will decrease. We can thus form InGaN QDs by depositing another 4.5 MLs of InGaN. In other words, such a growth interrupt method could be used to prepare InGaN QDs without the use of surfactants or anti-surfactants, and the size of QDs formed by such a method should be small enough to show zero-dimensional quantum effects. One other advantage of such method is that we should be able to control the physical properties of InGaN QDs by adjusting interruption time and/or interruption temperatures easily. Note that this result has been reproduced in our MOCVD system. Fig. 2 shows the room temperature PL spectrum observed from InGaN QDs formed by growth interrupt method. It can be seen that PL peak position of the growth interrupt sample is located at about 2.68 eV (462 nm) with a narrow full width at half maximum (FWHM) of about 92 meV. According to our previous experience, typical FWHM of room temperature PL spectrum is around 100 meV for InGaN QW samples grown in our MOCVD system. Although we expect that fluctuations in QD size and indium composition could result in a broad PL spectrum, the 92 meV PK FWHM observed from the QF sample is even smaller than those observed from typical quantum well samples. Such a result could probably be attributed to the large effective mass in this material system [9]. The reasonably sharp 92 meV PL FWHM also suggests that InGaN QDs formed by MOCVD Fig. 2. Photoluminescence from InGaN QDs at room temperature. L.-W. Ji et al. / Materials Letters 57 (2003) 4218–4221 growth interrupt are potentially useful in nitride-based optoelectronic devices. With the optimization of QD formation, we should be able to further improve the optical properties of these nitride-based QDs. In conclusion, it has been demonstrated that we can use interrupted growth method in MOCVD to control the growth of InGaN layers and to grow nanoscale InGaN self-assembled QDs. With a 12-s growth interrupt, we successfully formed InGaN QDs with a typical lateral size of 25 nm and an average height of 4.1 nm. The QD density is about 2 1010 cm 2. Strong PL emission of InGaN nanostructure was observed at room temperature with a FWHM of about 92 meV. These results suggest that such QDs are potentially useful in nitride-based optoelectronic devices. Acknowledgements This work was financially supported by the National Science Council of Taiwan (Project No. NSC 90-2215-E-006-024). References [1] S. Nakamura, M. Senoh, N. Iwasa, S. Nagahama, Jpn. J. Appl. Phys. 34 (1995) L797. [2] I. Akasaki, H. Amano, Jpn. J. Appl. Phys. 36 (1997) 5393. [3] W.C. Lai, S.J. Chang, M. Yokoyama, J.K. Sheu, J.F. Chen, IEEE Photonics Technol. Lett. 13 (2001) 559. [4] S. Nakamura, S. Pearton, G. Fasol, The Blue Laser Diode, Springer, Berlin, 2000. [5] Y. Narukawa, Y. Kawakami, M. Funato, S. Fujita, S. Fujita, S. Nakamura, Appl. Phys. Lett. 70 (1997) 981. [6] S.F. Chichibu, A.C. Abare, M.S. Minsky, S. Keller, S.B. Fleischer, J.E. Bowers, E. Hu, U.K. Mishra, L.A. Coldren, S.P. DenBaars, S. Sota, Appl. Phys. Lett. 73 (1998) 2006. [7] K.P. O’Donnell, R.W. Martin, P.G. Middleton, Phys. Rev. Lett. 82 (1999) 237. [8] B. Damilano, N. Grandjean, S. Dalmasso, J. Massies, Appl. Phys. Lett. 75 (1999) 3751. 4221 [9] K. Tachibana, T. Someya, Y. Arakawa, Appl. Phys. Lett. 74 (1999) 383. [10] C. Adelmann, J. Simon, G. Feuillet, N.T. Pelekanos, B. Daudin, Appl. Phys. Lett. 76 (2000) 1570. [11] S. Tanaka, S. Iwai, Y. Aoyagi, Appl. Phys. Lett. 69 (1996) 4096. [12] X.Q. Shen, S. Tanaka, S. Iwai, Y. Aoyagi, Appl. Phys. Lett. 72 (1998) 344. [13] H. Hirayama, S. Tanaka, P. Ramvall, S. Keller, Y. Aoyagi, Appl. Phys. Lett. 72 (1998) 1736. [14] J. Zhang, M. Hao, P. Li, J. Chua, Appl. Phys. Lett. 80 (2002) 485. [15] J.K. Sheu, S.J. Chang, C.H. Kuo, Y.K. Su, L.W. Wu, Y.C. Lin, J.M. Tsai, R.K. Wu, G.C. Chi, IEEE Photonics Technol. Lett. 15 (2003) 18. [16] Y.C. Lin, S.J. Chang, Y.K. Su, T.Y. Tsai, C.S. Chang, S.C. Shei, S.J. Hsu, C.H. Liu, U.H. Liaw, S.C. Chen, B.R. Huang, IEEE Photonics Technol. Lett. 14 (2002) 1668. [17] Y.K. Su, S.J. Chang, C.H. Ko, J.F. Chen, W.H. Lan, W.J. Lin, Y.T. Cherng, J. Webb, IEEE Trans. Electron Devices 49 (2002) 1361. [18] Y.K. Su, S.J. Chang, C.H. Chen, J.F. Chen, G.C. Chi, J.K. Sheu, W.C. Lai, J.M. Tsai, IEEE Sens. J. 2 (2002) 366. [19] S.J. Chang, C.H. Kuo, Y.K. Su, L.W. Wu, J.K. Sheu, T.C. Wen, W.C. Lai, J.F. Chen, J.M. Tsai, IEEE J. Sel. Top. Quantum Electron. 8 (2002) 744. [20] C.H. Chen, S.J. Chang, Y.K. Su, J.K. Sheu, J.F. Chen, C.H. Kuo, Y.C. Lin, IEEE Photonics Technol. Lett. 14 (2002) 908. [21] T.C. Wen, S.J. Chang, L.W. Wu, Y.K. Su, W.C. Lai, C.H. Kuo, C.H. Chen, J.K. Sheu, J.F. Chen, IEEE Trans. Electron Devices 49 (2002) 1093. [22] L.W. Wu, S.J. Chang, T.C. Wen, Y.K. Su, W.C. Lai, C.H. Kuo, C.H. Chen, J.K. Sheu, IEEE J. Quantum Electron. 38 (2002) 446. [23] C.H. Kuo, S.J. Chang, Y.K. Su, J.F. Chen, L.W. Wu, J.K. Sheu, C.H. Chen, G.C. Chi, IEEE Electron Device Lett. 23 (2002) 240. [24] S.J. Chang, W.C. Lai, Y.K. Su, J.F. Chen, C.H. Liu, U.H. Liaw, IEEE J. Sel. Top. Quantum Electron. 8 (2002) 278. [25] C.H. Chen, S.J. Chang, Y.K. Su, G.C. Chi, J.K. Sheu, J.F. Chen, IEEE J. Sel. Top. Quantum Electron. 8 (2002) 284. [26] C.H. Chen, Y.K. Su, S.J. Chang, G.C. Chi, J.K. Sheu, J.F. Chen, C.H. Liu, U.H. Liaw, IEEE Electron Device Lett. 23 (2002) 130. [27] N. Grandjean, J. Massies, Appl. Phys. Lett. 72 (1998) 1078. [28] K.N. Tu, J.W. Mayer, L.C. Feldman, Electronic Thin Film Science, Macmillan, New York, 1992.

© Copyright 2026