View PDF - Conference Proceedings

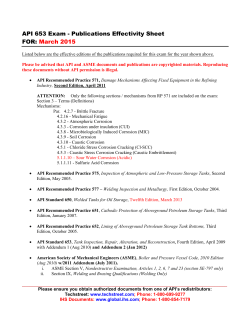

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS 345 E. 47th St, New York, N.Y. 10017 97-GT-300 The Society shall not be responsible for statements or opinions advanced:in papers or ceicussion at meetings of the Solety or of its Divisions or Sections, or printed in its publications. Discussion is printed only d the paper is published in an ASME Journal. Authorization to photocopy material for Internal or personal use under circumstance not falling within the fair useiprovisions of the Copyright Act is granted by ASME to libraries and other users registered With the Copyright Clearance Center (CCC) Transactional Reporting Service provided that the base fee of S0.30 per page S paid directly to the CCC, 27 Congress Street Salem MA 01970. Requests tor special permission or bulk reproduction should be addressed to the AWE Tectnimil Publishing Department All Rights Reserved CopyrbaM 0 1997 by ASME Printed in U.S.A , MATERIALS ISSUES FOR HIGH-TEMPERATURE COMPONENTS IN INDIRECTLY-FIRED CYCLES Ian G. Wright 111111111111111111111 Oak Ridge National Laboratory 1 Bethel Valley Road Oak Ridge, Tennessee 37831 John Stringer Electric Power Research Institute 3412 Hillview Avenue Palo Alto, California 94303 ABSTRACT Indirectly-fired cycles provide one means of using a fuel other than natural gas or distillates of various purities to generate power using a gas turbine. In a closed cycle, the fuel typically is used to heat a clean working fluid which is then expanded through a gas turbine, after which it is cooled and recompressed before being recirculated through the heating circuit. In an open cycle, the heated working fluid (usually air) is exhausted to the atmosphere after expansion in the turbine and passage through heat recovery devices. In both cases, the temperature of the working fluid may be boosted before entry to the turbine by supplementary firing of a premium fuel such as natural gas in a topping combustor. A major advantage of such indirectly-fired cycles is that the concerns arising from the use of a dirty fuel in other advanced cycles are confined to the fireside surfaces of the heat exchange equipment, whereas the gas turbine is exposed to a relatively benign environment. One limitation of such systems is that the emissions problems are the same as for a conventional coal-fired boiler although, on an power outputnormalized basis, the emissions from an indirectly-fired cycle may be lower. The requirements of the potential candidate materials for the various components in the circuit are discussed, and the critical issues for each are identified. (2250°F) with a additional ceramic heat exchanger. Current programs involving indirectly-fired gas turbine cycles are aimed at high cycle efficiencies, of the order of 47 percent based on the higher heating value (HHV) of the fuel, and involve open cycle systems in which air is heated to 760°C (I400°F) in a metallic heat exchanger, followed by further heating to 982°C (1800°F) in a natural gas-fired ceramic heat exchanger [Klan, 1993, 1994; Robson, et a]., 1996]. A variant of this approach is where part of the coal is pyrolyzed to produce the fuel gas used to fire the ceramic heat exchanger or the turbine; in that case the air entering the turbine is heated to 1288°C (2350° F). A further program envisions using a coal-fired ceramic heat exchanger for the whole duty of heating air to I200°C (2I92 ° F) [LaHaye, et al., 19951. Successful implementation of indirectly-fired cycle technologies will require the development of a durable coal-fired heat exchanger capable of heating the working fluid to very high temperatures, in addition to adapting a gas turbine for this particular duty. This paper discusses the materials issues associated with the heat exchanger section of indirectly-fired cycles. GENERAL DESCRIPTION OF MAJOR COMPONENTS INTRODUCTION Interest in increasing the efficiency of coal-fired power plants has led to the examination of alternatives to the steam boilerRankine cycle systems, for which increases in efficiency have been limited by the slow progress in improving the ability to handle steam at temperatures much in excess of 565°C (I050°F), as well as by the unavailability of easily accessible sources of naturallyoccurring low-temperature cooling water. Indirect-firing of gas turbines in open or closed cycles is one approach to linking the highe efficiencies possible via the Brayton cycle with coal asthe fuel. An experimental program in the 1980's [Campbell and Lee, 1982) demonstrated a coal-fired, low-emissions heat exchanger (fluidized-bed combustor) capable of heating air to 843°C (1550°F) in a metallic heat exchanger, and to 954°C (1750°F) or I232°C Figure 1 shows a schematic diagram of a hypothetical coal-fired open-cycle system constructed so as to illustrate the major components of interest. Considerable license has been taken in suggesting locations and interconnections of components that are not necessarily those that would maximize the system efficiency. Also, no provision has been made for the interconnections needed to facilitate part-load operation. In addition, no indication has been offered of any energy extraction from the flue gas stream from the coal-fired heat exchanger although, in practice, some fonn of heat recovery boiler and steam turbine system probably would be used. The main heat exchanger has been deliberately drawn to resemble the configuration of a modem coal-fired steam boiler, so that the location of the components of interest has some practical logic, and the Presented at the international Gas Turbine & Aeroengine Congress & Exhibition Orlando, Florida —June 2–June 5,1997 Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 12/29/2014 Terms of Use: http://asme.org/terms environments to which specific components are exposed at a given location are well characterized. Given the importance of the spatial arrangement of the heat transfer surfaces with respect to the flame in controlling heat flux, fouling, erosion and corrosion, starting from a known configuration should allow a rational analysis of the probable implications of changes in size and location of the heat exchanger components of interest. use of a modified combustor on the gas turbine, with the associated increase in capital cost. Figure 2 shows a version of the hypothetical plant for operation in closed-cycle mode. The major differences are that the working fluid and the system pressure can be chosen to optimize the heat transfer properties (although in this paper the working fluid is assumed to be air). Also, the turbine in a closed cycle is used simply to expand the gas and does not involve any combustion. Following expansion in the closed-cycle turbine, the working fluid is further cooled in a recuperator (which may preheat the combustion air, or may simply reject heat to a cooling tower) before re-entering the compressor. A complicating factor is that careful control of the fluid flow to the turbine compressor must be exercised in a closed cycle to ensure its proper functioning; this requires an ability to adjust the temperature of the inlet fluid, and emphasizes the importance of the functioning of the recuperator. Another difference is that in a closed cycle supplementary firing of a premium fuel to increase the Rrr requires a separate topping combustor and heat exchanger to heat the working fluid. Figure 1. Schematic Elevation of a Coal-Fired OpenCycle Gas Turbine System The working fluid is air which is compressed in the turbinedriven compressor before it enters the main body of the 'conventional' heat exchanger (conventional in the sense that it uses metallic alloys). There the air is heated to a temperature consistent with the maximum practical operating temperature of the metallic materials used before passing to the advanced, hightemperature heat exchanger which, in this case, is taken to be ceramic. The conventional heat exchanger is located in the furnace zone for the same reasons as in a coal-fired boiler, to minimize fireside corrosion problems by arranging for the coolest metal surfaces to contact the highest-temperature gas, as well as to provide an efficient means of containing the flame. The maximum working fluid temperature is attained in the ceramic heat exchanger, which may be located at the top of the furnace to permit radiant heating while avoiding direct contact with molten coal ash or slag, or may be sited deeper in the furnace zone to take advantage of increased radiant heat flux from close proximity to the fireball, if contact with molten ash or slag is acceptable. After expansion in the turbine, the working fluid may be further used as a heat source to raise steam in a heat recovery steam generator or, as suggested in Fig. 1, to preheat the air entering the conventional heat exchanger before being used as combustion air for firing the heat exchanger, and then exhausted to the atmosphere. Figure 2. Schematic Elevation of a Coal-Fired Closed-Cycle Gas Turbine System The differences in heat transfer properties can lead to a significantly smaller heating surface requirement for a closed cycle compared to an open cycle, for the same heat absorption/power output. Campbell and Lee (1982) indicate that from a cycle performance viewpoint it is desirable to limit the pressure drop across the heat exchanger to 3 to 5 percent of the inlet pressure. Since it is important that the wall temperature of the fired surfaces is maintained as close as possible to the working fluid temperature, especially in the high heat flux regions of the radiant surface where the flame temperature exceeds the melting temperature of the alloys used, matching the heat flux to the coolant mass flow at the lower inlet pressures of open cycles is a non-trivial problem. Further, close control of the temperatures of the radiant heat transfer surface leads to the need for good flame stability, as well as avoidance of spiking from slagging and deslagging events. Hence, the ability of a closed cycle heat exchanger to operate in a high heat flux zones might also result in a simpler design. Working fluid considerations are further discussed in Appendix I. Since the power and efficiency of the Brayton cycle is a direct function of the turbine rotor inlet temperature (Eli), it is desirable to maximize this temperature. For modern, high-efficiency gas turbines, the FUT is typically of the order of I288°C (2350°F), and is projected to rise to 1450°C (2642°F) in advanced land-based gas turbines. Since these very high temperatures may not be readily achievable using the heat exchanger alone, at least in the firstgeneration units, one option is to fire a small amount of a supplemental premium fuel in the turbine to further raise the temperature of the working fluid. This approach would entail the The cost-benefit arguments concerning the use of some level of supplementary firing are addressed in the U.S. Department of 2 Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 12/29/2014 Terms of Use: http://asme.org/terms Energy's High Performance Power Systems program [Klara, 1994], in which air is heated to 8I6°C (I500°F) in a coal-fired heat exchanger and then further heated to 1260°C (2300°F) by natural gas. A major advantage of the topping combustor is that it allows the ceramic heat exchanger to be operated at a maximum temperature commensurate with the strength and corrosion capabilities of the material used, and also provides the ability to change that temperature as experience accumulates. Obviously, there is a tradeoff between the cost of the extra components required and the premium fuel used with the increased reliability of the system. In the limit, the topping combustor might be absent, or may totally replace the advanced heat exchanger in Figs 1 and 2. Thus there is a strong incentive for increasing the reliable temperature capability of the coal-fired heat exchanger to decrease the requirement for supplemental firing in the topping combustor. Figure 3 from Campbell et al. (1980) shows the relationship of Rif to the overall efficiency of a closed-cycle system using a coalfired heat exchanger. System efficiencies in the range of 40 to 47 percent (HHV) for a simple, power-only 'closed-cycle gas turbine system are suggested for a RIT of the order of that of state-of-the-art power generation gas turbines, that is 1288°C (2350°F). Note that they set the maximum temperature of the air exiting the metallic heat exchanger at around 870 °C (1600°F), and used a 'primary' ceramic heater for heating the air from 870 to 982°C (1600 to I800°F). The maximum duty for the heat exchanger materials is to contain the working fluid at the maximum temperature and pressure consistent with the turbine design, while providing sufficient resistance to the working fluid and fireside environments to give an . acceptable lifetime for the heat exchanger. For an open-cycle system the maximum system pressure will correspond to the design pressure ratio of the turbine which, for modem power generation gas turbines ranges from approximately 10 to 30; hence, the maximum pressure would be approximately 1.1 to 3.1 MPa (162 to 456 psia). In a closed cycle, the system operating pressure is determined by the design and operating characteristics of the compressor (Lee, et al, 1980); small gas turbines (<50 MW) typically require pressures in the range 0.4 to 3.4 MPa (60 to 500 psia) for good compressor efficiency, whereas larger machines (50 to 350 MW) operate best at pressures from 3.4 to 6.9 MPa (500 to 1,000 psia). At the higher pressures, the problem of ensuring leak tightness of joints is increased, which requires extra care in design and initial assembly, as well as in materials selection to ensure that the potential effects of aging and corrosion are assessed. This is especially important for a closed cycle using a high-value working fluid. For a heat exchanger surface in the form of a tube, the hoop stress corresponding to these system pressures can be calculated from: SA = d.P12t, where d is the tube diameter, P is the internal pressure, and t is the wall thickness. Assuming a tube 5.1 an (2 in.) in diameter with a wall thickness of 6.4 mm (0.25 in.), the hoop stress ranges from 4.5 to 12.4 MPa (0.65 to 1.8 ksi) for an open cycle system, to 1.7 to 13.8 MPa (0.24 to 2 ksi) for a closed cycle system based on a small turbine, and from 13.8 to 27.6 MPa ( 2 to 4 Icsi) for a large turbine closed-cycle system. Applying a design safety factor of 1.5, the required creep strength in the hoop direction at temperature would range from approximately 6.8 to 18.6 MPa (0.97 to 2.7 Icsi) for most open cycle turbine conditions, 2.6 to 20.7 MPa (0.36 to 3) for closed cycle turbines up to 50 MW, and from 20.7 to 41.4 NfPa (3 to 6 hi) for closed cycles from 50 to 350 MW. Hence, a hoop strength of 21 MPa (3 ksi) is sufficient for operation of the heat exchanger with any current gas turbine in an open cycle, and up to 50 MW in closed cycle, whereas larger closed cycle machines (50 to 350 MW) require tubing hoop strengths up to approximately 42 MPa (6 hi). (Si,) MATERIALS SELECTION CONSIDERATIONS In practice, the form of the heat exchanger surfaces may be considerably different from those in a steam boiler, and there will be other differences such as the fact that the lower-temperature portion of the conventional heat exchanger will be significantly smaller, since there is no requirement to provide any latent heat of vaporization. Nevertheless, the fireside corrosion problems will be similar to those in current coal-fired boilers, depending on the local gas and metal temperatures. The gas turbine materials problems are essentially the same, or less severe, than in a conventionally-fired turbine using a clean fuel. Conventional Metallic S 732°C/1350°F1 Heat Exchanger (Tm In current coal-fired steam boilers, the maximum operating temperature experienced by pressure boundaries does not exceed approximately 732°C (I350°F). The application of heat transfer surface materials in steam boilers is governed by the ASME Boiler and Pressure Vessel (BPV) Code. This requirement has resulted in the use of relatively few alloys in this application; since Codequalification requires the generation of long-term creep strength data, the qualification process for new alloys is relatively lengthy (and expensive). (538) (816) (1093) It is expected that the alloy selection criteria for steam boilers for metal temperatures (T.) up to approximately 732°C (1350°F) would be used for any coal-fired heat exchanger, since the internal steam pressures are of the same order (up to 25 MPa/3.6 ksia) as the maximum pressures contemplated for the working fluid in open- and closed-cycle systems, there is a large database of experience of alloy performance, and the construction techniques and practices have been well proven. Hence, the selection of materials for the heat exchanger surfaces of the conventional metallic heat exchanger in the radiant furnace zone would start with seamless carbon steel or T-I I (Fe- I.25Cr-0.5Mo) tubes; the maximum recommended use (1371) Rotor inlet Temperature 'Fr) Figure 3. Variation of Efficiency of a Closed-Cycle Gas Turbine With Turbine Inlet Temperature (after Lee et al., 1980) 3 Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 12/29/2014 Terms of Use: http://asme.org/terms High-Temperature Metallic Heat Exchanger (Tin a 732°C/1 350°F) Swindeman and Marriott (1994) and Ruth and Birlcs (1995) recently assessed alloy properties required for power generation plants as a function of increasing plant efficiency. The number of alloys identified as having potential for application at the higher temperatures decreased rapidly above approximately 815°C (I500°F). The combination of properties desired in alloys for use in the high-temperature metallic heat exchanger is difficult to achieve, since the alloys must exhibit: • increased creep strength, • resistance to corrosion from the fireside environment, • corrosion resistance to the working fluid environment, and • ability to be fabricated by reasonable techniques. temperature of these alloys in coal-fired boilers [Dooley and McNaughton, 1996] are 454 to 510°C (850 to 950°F) and 552 to 566°C (1025 to 1050 °F), respectively. The water/steam-cooled furnace wall tubes in steam boilers operate at metal wall temperatures sufficiently low that they will provide service lives of >2 x 10 5 hours under all conditions except when direct flame impingement occurs. The use temperatures of these tubes are corrosion-limited, not creep-limited. However, the forms of fireside corrosion experienced by low-alloy steel tubes in this location in coal-fired systems are well documented for the coal types used in the U.S. [Stringer and Wright, 1995], and guidelines for remedial measures are available [Dooley and McNaughton, 1996]. Given that air as a working fluid will not have the heat absorption capacity of steam-water mixtures (no latent heat buffer) that allows excursions in heat flux without significantly increasing tube wall temperature, it may be necessary to specify an alloy with increased resistance to high-temperature oxidation, especially for the high heat flux areas. Alloys for use in this location will be the same as those considered for advanced steam condition plants (steam at 33 MPa/4.8 ksi and 625°C/I157°F) [Blum, 1994] and include 1-22 (Fe2.25Cr-IMo; 580 to 602°C/I075 to 1115°F) or modified versions of this alloy, T-5 (Fe-5Cr-0.5Mo), and possibly 1-91 (Fe-9Cr-IMo) if the increased cost can be justified by, for instance, the use of thinner Creep Strength Alloys approved or which are being Wrought Alloys: considered for approval (BPV Code Section VIII, Division 1) for service at temperatures at or above 732°C (1350°F) are included in Table I. Following Ruth and Birks (1995), Fig. 4 plots the allowable stress as a function of temperature for some of these alloys for the temperature range of interest; the horizontal shaded boxes indicate the requirements for the two regimes of interest: open cycle (all turbine sizes) and closed cycle <50 MW, and closed cycle >50 MW. Note that the requirements for small closed cycle systems are equivalent to those for open cycle systems. The alloy with the highest allowable stress at 899°C (I650°F) is Alloy 230. with Inconel 617 a close second. These data indicate that this alloy would be useable in an open cycle or small turbine closed cycle system up to at least 860 °C (1580°F), and up to at least 780°C (1436°F) in a closed-cycle heat exchanger for a large turbine. These alloys represent the maximum practical performance for wrought alloys strengthened by the conventional routes of solid solution alloying and carbide or other precipitation. The maximum temperature duty in steam boilers typically is handled using type-300 series stainless steels such as 347H (704°C; 1300°F), 304H (704-760°C; 1300-1400°F); or 321H (760815°C; 1400-1500°F) in the outlet sections of the superheaters; these metal temperatures also are lower than those specified by the BPV Code (except for type 32IH) because of fireside corrosion considerations. For extremely corrosive duty, type 310 clad on a higher-strength steel or Inconel 671 clad on lncoloy 80011 is used. The compositions of these alloys are given in Table 1. Table 1. Compositions of Candidate Alloys for the High-Temperature Heat Exchanger Alloy 304H 321 34711 80011 NF709 I 253MA 556 HR6W 31011 HR3C I 230 Inconel 617 HRI60 Inconel 671 Haynes 188 MaxU se T°C• 732 843 899 899 732 899 899 816 Chemical Composition, weight percent Fe Bal. Bal. Bal. Ni 8-12 8-12 9-13 Bal. Bal. Bal. Bal. 30-35 25 10-12 20 Bal. Bal. Bal. 1.3 0.0 3.5 43 20 20 Bal. Bal. Bal. Bal. 20-24 3 Cr 18-20 18-20 17-19 Al 0.5 18 19-23 20 20-22 22 0.28 12 27-33 23 25 25 22 22 26-30 Co Ti Nb Mo 10xC 10x C 0.4 1.5 3 0.1 0.2 0.5 1 0.1 0.15 0.6 0.05 1 0.2 0.02 0.3 0.2-0.8 1.4-2.0 0.3 Other 1.2 9 I 0.4 0.2 2.4-3.0 0.2-0.5 21-23 N 0.03-0.08 Ce 2.5W, 0.6Ta, 0.02Zr 6W 0.2N, 0.25N 0.4 48 Bal. C 0.08 0.08 0.08 0.1 0.5 0.25 0.4 1.2 Si 0.5 0.75 0.75 0.15 14W, 0.3La 0.05 0.07 0.1 1W, 1 Mn *BPV Code data 4 Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 12/29/2014 Terms of Use: http://asme.org/terms 13-15W, 0.02-0.12La 0.02La, Creep rupture data in the longitudinal direction for Inconel MA956, calculated from 213 of the reported 10,000 hour rupture strength [McColvin and Smith, 1987], are shown as a curve in Fig. 4. Data from a different source [Hurst, 19961 for longitudinal as well as circumferential creep strength at I100°C (2012°F) for the three ODS FeCrAl alloys in Table 2 were used in Fig. 4 to indicate the range of properties. Using only the circumferential data as representative of the capabilities of these alloys in a high-temperature heat exchanger, it is projected that the best of these alloys could be used up to at least 935°C (17)5°F) for all open-cycle sizes considered and small turbine (<50 MW) closed systems, and up to I100°C for lower pressure-ratio turbines in an open cycle system. Obviously these projections only suggest the potential for these alloys, and more extensive data are needed. Nevertheless, the very conservative approach of using a 50 percent safety factor plus the 33 percent margin associated with the BPV criteria lends some credibility to the data shown in Fig. 4. Metal Tang:ream •C Figure 4. Allowable Stresses for Qualified and Pending ASME Boiler and Pressure Vessel Code High-Temperature Alloys (data for MA956 and other ODS alloys were based on 2/3 10,000 hr creep rupture strength) Oxide Dispersion-Strengthened Alloys: There have been significant developments in recent years in alloys strengthened by an oxide dispersion (ODS) which can provide creep strength up to approximately 90 percent of the alloy melting temperature. Table 2 shows the chemical compositions of three commercial iron-based ODS alloys; the melting point of these alloys is 1480°C (2696°F). Table 2. Compositions of Commercial Ferritic Oxide Dispersion-Strengthened Alloys Fe Bal. Composition, weight percent Cr Al Ti Mo 4.5 20.0 0.5 Bal. Bal. 16.5 20.0 Alloy Inconel MA956 0DM751 PM2000 4.5 5.5 1.5 0.6 0.5 Y203 0.5 0.5 0.5 The ferritic ODS alloys based on Fe-Cr-Al have the potential for application at higher temperatures than the modified conventionally-strengthened alloys in which the strengthening mechanisms degrade as the precipitated phases become less stable with increasing temperature. Although the properties of this class of alloys appear very promising, data are available usually for only relatively short times, and none these alloys has been BPV Codequalified. There is a strong anisotropy in the creep strength of these alloys. Since the microstructuml features associated with the strengthening mechanism are usually aligned in the longitudinal (axial) direction, maximum creep strength is in this direction. Progress in processing and microstructural control has resulted in increases in the circumferential creep strength, although it is still significantly lower than the strength in the axial direction. Unfortunately, the BPV Code does not consider the effects of corrosion or of fatigue on the alloy strength limitations, and the design engineer must decide his own allowances. Given a reasonable understanding of the corrosion behavior of these alloy types, a corrosion allowance factor can be produced if corrosion information is available for the specific environment of interest. Similarly, although there is no unified methodology for assessing the effects of fatigue on tube life, boiler makers have their own criteria. It appears that specific testing in the temperature and environmental regimes of interest will be required to provide some guidance in these areas. Fabrication. In general, the wrought, high-temperature alloys such as Alloy 230 and Inconel 617 are fabricable by conventional methods with some modifications due to their high strength. Since the issues specific to fabrication of these alloys are widely known, they are not discussed further here. The ODS alloys are not in wide use in tubular form, but are routinely available in lengths up to 3.3 m (II ft). For full-scale applications, tube lengths of 8 m (26 ft) would be desirable. Fabrication of ODS alloys requires a different approach than with conventional wrought alloys because of the critical dependence of their high-temperature strength on the microstructure. The ductilebrittle transition temperature of these alloys (critical temperature for 50% risk of brittle failure) is 50-75 ° C (122-167°F)[McColvin, 19951, so that they must be worked hot; they can be readily bent after heating to, for instance, 300°C (572°F). Plasma cutting and wire cutting should be avoided since these processes result in cracks forming in the alloy surface [Sporer, 19951. These alloys are readily machinable using conventional methods with appropriate parameters, but sharp corners should be avoided in component design. Electrode discharge machining results in cracking in the recast layer; this can be overcome with care, but then the process is very slow. Some component designs that work well incorporate a combination of welding and mechanical fastening. Overall, however, it is considered best to avoid welding by design, or by riveting. Although ODS alloys can be successfully fusion welded, such joints have a significantly reduced load-bearing capability at temperature. This is because fusion locally destroys the controlled distribution of the dispersed phase and disrupts the continuity of Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 12/29/2014 Terms of Use: http://asme.org/terms the microstructure, which are the essential features that provide high-temperature creep strength. Further, fusion welding can result in cracking at grain boundaries. Laser welding can be performed such that the dispersoid is retained, but it is typically coarsened and, as with normal fusion welding, the grain structure of the alloy is destroyed and some grain boundary cracking usually occurs. No matter how good the weld, the grain structure and dispersoid distribution will be disrupted [Wallach, 1995]. Nevertheless, these changes in structure can be quite acceptable if the weld is outside the area of critical interest. deposits of nominally dry flyash. The temperature-dependence of molten alkali sulfate-accelerated corrosion is considered to follow a 'bell-shaped' curve, as is illustrated in Fig. 5 [after Tamura, et al., 1985] for several of the alloys of interest exposed to a simulated flue gas and covered with a simulated deposit for 100 hours. For essentially all alloys tested, the rate of attack accelerates rapidly with increasing temperature above approximately 600°C (I112 °F), reaches a maximum, and then rapidly decreases. The actual temperatures may shift with the specific molten salts involved, the temperature difference between the gas and the alloy surface, and the specific alloy. The reduced attack at the higher temperatures is thought to result from the instability of the alkali sulfate species involved, possibly as a result in a decline in the S02/S03 concentration in the flue gas. As evident from Fig. 5, type 310 stainless steel has the best resistance of the 300-series steels, and the higher-strength alloys typically exhibit increasing resistance with increasing chromium content. The highest corrosion resistance usually is found with Inconel 671 (Ni-48Cr), which sometimes is used as a cladding. Strengthening additions such as Mo can have a detrimental influence on the susceptibility to molten salt corrosion. Solid state bonding, whether by friction welding or explosive joining, is a feasible method for joining ODS alloys. This process results in discrete interfaces with unique restructured geometries and may cause distortion of the grain size and direction. A variant of friction joining involves a third body, which provides an essentially mechanical bonding of the components of interest and does not necessarily involve any melting [Thomas, et al., 1994]. This technique has promise for joining ODS alloys to themselves and to other difficult-to-join materials. Explosive bonding can readily be used for tubes, but local melting must be avoided. British Gas [Starr, et al., 19941 successfully constructed a harp-type heat exchanger that used ferritic ODS tubes (of 0DM751) by explosively bonding the ODS tubes to wrought alloy stubs that were then welded to the headers. The British Gas heat exchanger was part of a closed-cycle demonstration unit that was run successfully with a working fluid outlet temperature in excess of 1100°C (2012°F) [Mabbutt, 1995]. Although the header and stubs were in this case made of a wrought alloy with lower creep strength than the ODS alloy, the use of thicker sections for the stubs was practically acceptable. This approach allows for straightforward field replacement of individual tubes, but requires that a damaged ODS tube be completely replaced rather than repaired. At metal temperatures higher than the upper minimum in the bell-shaped curve but below the melting points of any simple salts that might deposit, the main corrosion mechanisms would be expected to involve gas-phase oxidation, sulfidation or carburization. Field corrosion probe tests in the superheater regions of steam boilers fired by the types of U. S. coals expected to produce molten salt-related fireside corrosion were carried out at metal temperatures in the range 538 to 871°C (1000 to 1600°F) as part of a program to evaluate the performance of alloys capable of use in higher-temperature cycles [Plumley, et al., 19791 After exposures made for up to 8,000 hr, the performance of alloys Inconel 617 and Haynes 188 was ranked as very good, with metal loss less than 0.7 nm/hr (0.25 mil/yr.), whereas type 310 stainless steel and Incoloy 800H lost 6 and 5 xun/hr (1.9 and 1.6 mil/yr), respectively. Essentially, these alloys experienced high-temperature oxidation. The lack of accelerated corrosion at the temperatures representing the maximum in the bell-shaped curve was attributed to coal blending being practiced to avoid this form of corrosion. Transient liquid phase qui joining is a further possible approach. If UP joining is done before the heat treatment used to grow the large grains, the grains can be grown through the joint. Overall, with ODS alloys it is difficult to attain the properties of the parent material in a joint. However, there are approaches to design and materials combinations that can be optimized for specific applications. If the joint could be kept out of the most severe service, at least the corrosion rate should be reduced compared to the rest of the alloy. Krause et al., (1994) also reported field corrosion data obtained in support of a closed-cycle gas turbine system with a maximum working fluid temperature of 843°C (1550 ° F). Those results were obtained from both superheater and furnace wall regions of coal-fired boilers and indicated that, in pulverized coal-fired systems burning coal with sulfur levels in the range 0.8 to 3.1 percent and alkali-plus sulfur-related corrosion indices (Borio, et al., 1972) up to 3.8, type 304H stainless steel exhibited high corrosion rates which led to the recommendation that it not be used at metal temperatures above 704°C (1300°F). In contrast, type 310H, and Alloys 800H and 617 showed evidence of forming protective oxide scales in 2,000 hour exposures at temperatures up to 871°C (1600°F); the projected corrosion rates were less than 6 run/hr (2 mil/yr). Environmental Resistance—Fireside. In addition to the limitations of the strengthening mechanisms employed in these various classes of alloys, at the higher temperatures environmental compatibility considerations assume increasing importance. The sources of corrosion attack on the fireside circuit of coal-fired steam boilers, and the behavior of most candidate alloys at temperatures typically encountered in current boilers are reasonably well understood. The details have been exhaustively analyzed in a number of reviews [for instance, Stringer and Wright, 1995]. The potential for fireside corrosion can be minimized by ensuring that the heat transfer surfaces are located where any fuel particles entrained in the flue gas are solid, so that direct contact with molten ash or slag is avoided. The sources of corrosion then involve the temperature-driven acceleration of oxidation, sulfidation, "and/or carburization, as well as the possibility of localized attack by the formation of low-melting species such as alkali sulfates under The ferritic ODS alloys have excellent resistance to gas-phase oxidation, sulfidation, and carburization attack, but their corrosion resistance in the presence of molten alkali salts is not well established. Experience with molten salt corrosion in marine gas turbines suggests that alloys which form alumina scales would be expected to exhibit lower resistance to this form of attack compared to chromia scale-forming alloys. However, initial results from 4,000+ hr boiler probe tests suggest that some alumina scale-forming 6 Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 12/29/2014 Terms of Use: http://asme.org/terms A further point for consideration is that, above approximately 1025°C (1877°F) in static dry air environments and at temperatures as low as 800°C (1472°F) [Lowell, 1972] in flowing, dry air, the protective oxide scale of Cr203 formed on most of the solid solutionand carbide-strengthened high-temperature alloys can be further oxidized to 003 which is volatile. The rate of Cr03 formation and subsequent loss is controlled by diffusion across the aerodynamic boundary layer [Graham and Davis, 1971], so that the higher the gas velocity (the thinner the boundary layer), the more rapid the loss. Recent results [Opila and Jacobson, 1996] indicate that water vapor has a significant effect on scale volatility, such that the vapor pressure of an oxyhydroxide species, Cr02(OH)2, exceeds that of Cr03 by many orders of magnitude at temperatures below approximately 1100°C (2012°F) in an environment containing 10 percent by volume water vapor. This form of degradation not only removes chromium from the alloy, so affecting alloy strength as well as oxidation resistance, but also leads to deposition via condensation of Cr03 at some point downstream, which also may be undesirable. 160 _11140 2-5%0,-15%CO 2 -N t 34%Na 2 604-41% K 2 SO4 - 25%Fe,O, 140 -Ippa test 2 8 120 100 80 60 40 20 0 In high-temperature, high-gas flow applications (such as gas turbine hot gas path components), alloys or coatings that form a protective scale of the relatively non-volatile A1203 typically are used instead of Cr203 -forming alloys. There are techniques that could be used to provide protective alumina scale-forming coatings on the internal surfaces of tubing, although there is limited capacity for handling long tube lengths, and any effect of the heat treatment cycle involved on alloy properties would require consideration. Since the ODS alloys MA956, 0DM751, and PM2000 are alumina-formers, they would not require a coating on the working fluid side. 600 650 700 750 800 850 Temperature ( °C) Figure 5. Temperature-Dependence of Molten SaltAccelerated Fireside Corrosion of High-Temperature Alloys (after Tamura, at al., 1985) Ceramic Heat Exchanger (T, alloys (Fe3A1-based) may have corrosion resistance at least as good as the best chromia-forming alloys under conditions where the 300series stainless steels suffered accelerated attack [Slough, 19961. Apylronmental Resistance—Working 1100°C/2012°F1 Materials Selection. In 1989, a detailed assessment of the state of development of ceramic heat exchangers for pressurized duty concluded that a large gap existed between the perceived technology level and the actual design database, but that it was important to pursue the concept [Bevilacqua Knight Inc., 1989]. The areas of main concern were: (a) Lack of reproducibility of the structure and properties of the ceramic in the required sizes, including insufficient data on the size of critical flaws, effect of surface finish, and insufficient thermal shock capability. (b) Shortcomings in the then-current tube-string design including joint wear leading to leakage, effects of deposition on tube mechanical movement, and durability of seals; insufficient information on modes of degradation and failure; and concern that a single tube failure could result in the downstream failure of other tubes. (c) Lack of knowledge of the effects of corrosion, erosion, and deposition at the temperatures of interest with the range of available coals. Fluid. Resistance of the alloys to the high-velocity working fluid and, in particular, the ability to form a stable oxide scale that is adherent and will not produce particles of spatted oxide that would be an erosion threat to the gas turbine also requires attention at the higher temperatures. The rate of growth of oxide scales in air is typically faster than in steam at a given metal temperature, and the composition of the stales is likely to be different as a result of the different effective oxygen partial pressures of steam and air. It is likely that the available databases for scale growth and spallation in steam will need to be supplemented (or replaced); hence, there is a need for information on scale spallation behavior in air oxidation for all of the candidate alloys. The ferritic ODS alloys have outstanding resistance to scale spallation at high temperatures [Quadalckers, et al., 1994]. Long-term oxidation testing under temperature-cycling conditions has shown that these alloys essentially do not suffer scale spallation for several thousand hours; when spallation initiates it occurs as very small particles, and the alumina scale is reformed until the aluminum in the alloy is depleted to very low levels (of the order of 1.5 weight percent) before the onset of formation of voluminous iron-rich scales which could be a spallation-erosion threat. Substantial progress has been made in all of these areas. The leading candidate materials for this application are based on SiC in the form of high-density sintered ceramic, as siliconizcd SiC ( ■ 8 volume percent Si) or reinforced with SiC fibers. Oxide ceramics such as A1203 reinforced with SiC particles also are being considered [Natesan, et al., 1995]. High-purity, high-density (<3 percent porosity) SIC has high thermal conductivity and the 7 Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 12/29/2014 Terms of Use: http://asme.org/terms potential for very little change in mechanical properties up to approximately I500°C (2732°F); it also has good resistance to slow crack growth up to I200°C (2192°F). metallic inlet line. The configuration of the ceramic surfaces is dictated to some extent by the location of the heat exchanger with respect to the heat source and the need to handle running slag, ash deposition or clean gas. In one design, a gas-fired ceramic heat exchanger is located inside, near the outer diameter, of the main coalfired furnace [Solomon, et al., 1996], which allows the heat exchanger to be heated by radiation from the coal flame and by convection from the gas burner, but is susceptible to coal ash fouling. The heat exchanger is made from U-shaped tubes, and the gas flame fires along the channel formed by the stacked U-tubes. Aerodynamic cleaning of the tubes is accomplished by using a long gas flame fired at a slight angle to the axis of the channel. Mechanical Properties. The strength of a ceramic is dependent on the size and distribution of flaws, which are potential initiation points for fracture. Deformation of ceramics may Occur by diffusion and by grain boundary sliding, but at some critical stress intensity, crack growth will occur from existing flaws. As a result, the strength is expressed in statistical terms, usually based on the approach suggested by Weibull [see, for instance, Ashby and Jones, 19863 which provides a measure of the fraction of identical samples expected to survive loading to a specified tensile stress. The variability of the strength is indicated by the Weibull modulus, which is found finm testing. Hence, there is no single value for representing the strength of a ceramic. Implicit in this approach is the importance of the size and geometry of the part, as well as its surface finish. In practice, since a statistical approach to design implies that a failure will occur, the designer either needs to employ a very large safety margin until experience is gained with the specific material, or to devise a failure-tolerant design that allows easy maintenance. An understanding of the likely failure mode is essential for assessing the likely location of failure, the actions to be taken when a failure occurs, and the spare parts inventory needed. Joining the ceramic to itself, and to the header from the hightemperature metallic heat exchanger, still represents a challenge and probably will require continuing development A particular problem will be the application of expansion joints under conditions where a significant thermal and pressure differential exists across the tube wall, and where there is a strong possibility of high-temperature corrosion. A further complicating factor is the need to accommodate the different rates of heat-up and cool-down of the component parts, especially since these plants will likely experience some level of cycling duty. Environmental Resistance. The actual maximum temperature that can be realized in practice probably depends on the resistance of the ceramic to fireside corrosion in the location in the coal-fired furnace required to provide the desired heat flint The important measure of corrosion is its effect on the size and distribution of surface flaws that control the strength of the material. Hence, selective attack of features such as grain boundaries to create flaws or of pre-existing flaws must be minimized. As with some metallic alloys, measurements of long-time mechanical property data are sparse for ceramic materials. Some results from an on-going effort to generate such data indicate that, to achieve lifetimes approaching 100,000 hours in air for a commercial gas pressure-sintered Si3N4, a static tensile stress of 300 MPa (43.5 ksi) at 1038 and 1150°C (1900 and 2IO2°F), and 125 MPa (18 ksi) at 1350°C (2462°F) cannot be exceeded. For SiC, a static tensile stress of 300 MPa at I038°C, 250 MPa (36 ksi) at 1150°C, and 180 MPa (26 Its° at 1350°C cannot be exceeded. Failures in the SiC were a result of slow crack growth that initiated from the specimen surface, whereas it appeared that the fatigue failure in the Si3N4 was related to the creep mechanism [Wereszczak, et al., 1996]. Note that these strengths are all well in excess of those needed for the cycles indicated in Fig. 4. Silicon carbide typically forms a surface film of a-Si02 in oxidizing environments at high temperatures, which is protective (passive oxidation). Under certain conditions of reduced oxygen partial pressure, which vary with temperature, the oxide formed is SiO, which is volatile; this behavior is known as "active oxidation." Such conditions could occur in areas of a combustor which were persistently substoichiometric, as may be the case under some conditions of low-NO. operation, or under slag layers where unbumt carbon could create a locally reducing environment. Design Approaches. The features that require attention in any ceramic heat exchanger design are: • prediction of the stress distribution, especially around joints and at points of contact, • ability to maintain leak-proof joints, • design to avoid fireside fouling or incorporate methods to prevent or remove deposits, • strategies for repair or replacement in the field, and • resistance to thermal cycling. The configuration of the ceramic heat exchanger should utilize shapes for the heat transfer surfaces that minimize any tensile components of static or dynamic loading, including possible loads from the build-up of deposits that could be molten, hence strongly adherent. Various configurations of tubes have been extensively explored using detailed stress analyses [Dapkunas, 1988] as a guide. Designs have been based on U-tubes [Carpenter, et al., 1980] or on straight tubes [LaHaye, 1995; Shenker and Torpey, 19961, with emphasis on modular design to simplify manufacture and inspection, and on approaches to accommodate the mismatch in coefficient of thermal expansion between the ceramic headers and the The resistance of SiC to molten slags or molten alkali sulfate deposits is good if the deposit is acidic, but rapid attack can occur in basic melts [Ferber, et al., 1985]. The melting temperature and acid-base nature of slag or ash deposits from coals can be predicted from the coal composition and can be modified by coal blending or by the use of additives. Work in progress [Breder et at, 1996; flannel, 1996] is aimed at quantifying the effects of slags from a range of coals on the corrosion behavior and strength degradation of several candidate ceramics. Auxiliary Fired Heater/Topping Combustor In either open or closed cycles, some form of topping combustor appears to be an essential component for achieving acceptable cycle efficiencies. In an open cycle, the auxiliary fuel probably will be burned in a modified version of the combustor typically used on a fired turbine. The design of this combustor will be complicated by the need to handle the high-temperature air from the main heat 8 Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 12/29/2014 Terms of Use: http://asme.org/terms exchanger. The maximum temperature of the inlet air to the combustor in conventionally-fired turbines is significantly less than 871 °C (I600°F), so that modification to the cooling system used for the combustor can, or the use of materials such as ceramic matrix composites for the combustor liner will be necessary. conventional wrought alloys, for which the required data are being developed. The main issues concerning the application of these alloys are similar to those faced in coal-fired steam power plants, namely fireside corrosion in high-flux regions, including the performance of weldments, and scale spallation on the working fluid side at the higher temperatures. For the advanced alloys, the generation of long-term creep rupture data is needed. In the case where the fuel used in the gas turbine is pyrolysis gas derived from the coal [Shenker and Torpey, 1996], the materials selection for the transfer line from the pyrolyzer to the turbine is complicated by the need to handle a hot, reducing gas coupled with the need to avoid refractory linings which can potentially spall, leading to erosion of the turbine. Since the pyrolysis gas will probably carry entrained ash particles, the transfer line will likely contain a hot gas filter, in this case, refractory linings must be avoided only between the filter and the turbine. This ODS-ferritic alloys have demonstrated high-temperature strength capabilities, and have been successfully fabricated into a closed-cycle heat exchanger configuration. Because of the need to preserve the alloy microstructure of ODS alloys in the region where joints are made, there is a need for demonstration of the capabilities of the several available joining techniques in simulated service conditions. There is also need for the quantification of the fireside corrosion behavior in the regions of interest in a coal-fired system. Further developments of microstructural and processing control to increase in the creep strength in the circumferential direction are desirable to further increase the temperature capability of these alloys or allow the use of thinner sections. The cost of the ODS alloy tubes currently is very high, partly as a result of the low volume of current production. In a closed cycle the auxiliary fired heater or topping combustor will probably be a natural gas-fired heat exchanger, hence will require similar considerations to the main ceramic heat exchanger. Major differences will be the ability to better control the uniformity of the heat flux on the tubes and the absence of molten salt corrodents. For this unit, advantage probably could be taken of work on ceramic heat exchangers for gas turbine recuperators, which is aimed at turbine inlet temperatures in the range of I350°C (2462°F). In one example [Yoshimura, et al., 1995], SN-84 SiC was used for the tubes and tube-sheet, and a simple design was employed which involved straight ceramic tubes and a clamping arrangement using a compliant layer between the ceramic tubesheet and the metallic headers. One end of the ceramic tube bundle was free to elongate and rotate to accommodate changes caused by variation in heat distribution. A continuing need for the coal-fired ceramic heat exchanger is an adequate body of design data for the as-fabricated condition that will exist in commercial components. Inherent in this need is the ability to manufacture larger parts/longer tubes with a higher assurance of quality control. Techniques capable of identifying surface defects of the order of 10 gm under field conditions would greatly facilitate inspection and improve confidence in the operation of these components. Joining of ceramic-to-ceramic and to metals remains a challenge. For coal-fired applications, a major uncertainty for the realization of the potential of the ceramic heat exchanger is the effect of the fireside environment on the critical flaw size. Designs need to address the practical implications of tube failure and replacement in service. SUMMARY The materials available for construction of the heat exchangers required in indirectly-fired gas turbine cycles have been considered as three distinct classes: Conventional wrought ferritic and austenitic alloys which, as tubes 5.1 cm (2 in.) diameter and 6 mm (0.25 in.) wall thickness, are suitable for use to temperatures up to 9I5°C (I680°F) in an open-cycle system, and up to approximately 860 °C (I580°F) in a closed-cycle system with a small turbine. Oxide dispersion-strengthened (critic alloys which are capable of use to at least 935 °C (I715°F) for all open cycle sizes considered and small (<50 MW) closed-cycle turbine systems, and up to I100°C (20I2°F) for lower pressure ratio turbines in an open-cycle system. (iii) Ceramics which can be used in heating the working fluid to temperatures above approximately 935°C (1715°F). Overall, there are materials available that can enable the construction of externally-fired heat exchangers capable of delivering air at the desired pressures at temperatures up to 935 ° C (I715°F, open cycle and small closed-cycle) for an all-metallic system and to possibly I300°C (2372°F) for a metallic plus ceramic system. There are some gaps in the data required to commit to a fullsize plant, but there appears to be no reason why these needs cannot be met with properly focused research, The high temperatures possible with ODS alloys would allow the size of the following ceramic heat exchanger to be reduced, with the possibility that more appropriate or innovative designs could be better tailored to accommodate the needs of the ceramics, especially the difficult ceramic-to-metal joints. Some of the unique properties of the class (ii) and (iii) materials may render them unsuitable for the direct substitution of class (i) materials in conventional heat exchanger designs. This is not necessarily a drawback, since the most effective design of an indirectly-fired heat exchanger is likely to use different modules located in the gas path so that they encounter the most appropriate heat flux and corrosive environment. Such a modular arrangement also permits the design of each module to be most appropriate for the properties of the materials being used. The required strength and fabrication data are well established for the conventional alloys, and long-term environmental resistance data are being generated. This group also includes some advanced ACKNOWLEDGMENTS The authors are grateful the support of the Electric Power Research Institute, and of the Fossil Energy Advanced Research and Technology Development (AR&TD) Materials Program, U. S. Department of Energy, under contract DE-AC05-840R21400 with Lockheed Martin Energy Research, Inc. In addition, discussions with colleagues at the Oak Ridge National Laboratory: in particular, Drs. K. Breder, M. K. Ferber, It R. Judkins, Mr. It W. Swindeman, Dr. A. W. Wereszczak, and with Prof. N. Birlcs of the University of Pittsburgh are gratefully acknowledged. 9 Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 12/29/2014 Terms of Use: http://asme.org/terms REFERENCES Ashby, M. F., and Jones, D. It H., Chapter 18 in Engineering Materials 2: An Introduction to Microstructures, Processing, and Design, Intl. Series on Materials Science and Technology, Vol. 39, Pergamon Press (1986). Bevilacqua Knight Inc., Technology Assessments for Advanced Fossil Power Systems, EPRI Report No. GS-6165, Dec. 1989. Blough, J. L., and Stanko, G. J., "Fireside Corrosion Testing of Candidate Sup-eralloy Tube Alloys, Coatings, and Claddings— Phase II," Presented at the Tenth Annual Conf on Fossil Energy Materials, Knoxville, Tennessee, May 1996. (1996). Blum, It, "Materials Development for Power Plants with Advanced Steam Parameters-Utility Point of View," pp. 15-20 in Materials for Advanced Power Engineering, 1994, Part I, D. Coutsouradis, et al., Eds., Kluwer Academic Publishers (1994). Borio, It W., and Hensel, It P., "Coal-Ash Composition as Related to High-Temperature Fireside Corrosion and SO2 Emission Control", Trans. ASME. .1 Engg. Power, QL,1 pp. 142-7 (1972). Breder, K., and Lin, H. T, "Materials Support for HITAF," pp. 181-191 in Fossil Energy Program Annual Progress Report for April 1995 Through March 1996, ORNL-6902, June 1996. Campbell, J., Jr., and Lee, J. C., "Fired Heater Versus CCGT/Cogeneration Cycle Parameters," ASME Paper No. 82-GT187 (1982). Carpenter, H. W., Campbell, J., Jr., Russell, L. H., and Wright, D. E., "High-Temperature, Coal-Fired Combustor With Ceramic Heat Exchangers for CCGT Systems," Presented at the ASME Gas Turbine and Products Show, New Orleans, Louisiana, March 1980. Daplcunas, S. J., "Ceramic Heat Exchangers," Ceramic Bull., §2 (2), 388-391 (1988). Dooley, It B., and McNaughton, W. P., Boiler Tube Failures: Theory and Practice, Electric Power Research Institute (1996). Ferber, M. K., Ogle, J., Tennery, V. J, and Henson, T, "Characterization of Corrosion Mechanisms Occurring in a Sintered SiC Exposed to Basic Coal Slags," J. Amer. Ceram. Soc., 121 (4), 191 (1985). Shenker, J., and Torpey, M., "High-Performance Power System Development Including Scaling Considerations," Presented at the Intl. Joint Power Generation Conj., Houston, Texas (1996). Graham, H. C., and Davis, H. H., J. Am. Ceram. Soc., 5.4., 89 (1971). Hamel, S., "Effect of High-Temperature and Coal Slag Exposure on the Mechanical Properties of a SIC Ceramic," ORNL Summer Student Report (1996). Hurst, R., Private communication to I. G. Wright, Joint Research Centre, Petten, The Netherlands (1996). Klara, J. M., "HIPPS: beyond state-of-the-art, Part I," Power Engineering, .12, 37-39 (1993). Klan, J. M., "HIPPS can compete with conventional PC systems: Part II," Power Engineering, j3. 20-23 Jan (1994). Krause, H. H., Nagarajan, V., and Wright, I. G., "Fireside Corrosion of High-Temperature Heat Exchanger Materials Exposed in Pulverized Coal-Fired Boilers," Paper No. 174 presented at NACE Conference CORROSION/94, Baltimore, Maryland, March 1994. LaHaye, P. G., Strom-Olsen, J, Seger, I L., and Pickup, H., "Externally-Fired Combined Cycle Demonstration," pp. 55-64 in Proc. Advanced Coal-Fired Power Systems '95 Review Meeting, H. Ni McDaniel, D. I. Mollot, and V. K. Venlcataraman, Eds., DOE/METC-95/1018, June 1995. Lee, J. C., Campbell I., Jr., and Wright, D. E., "Closed-Cycle Gas Turbine Working Fluids," Presented at the ASME Gas Turbine and Products Show, New Orleans, Louisiana, March 1980; also, J. Engg. for Power, 220-228 (1981). Lowell, C. E., "A Scanning Electron Microscope Study of the Surface Morphology of TD-NiCr at 800°C to I200°C," Oxdtn. of Metals, 1 (3), 205-219 (1972). Mabbutt, Q. J., The British Gas Closed Cycle DemonstratorFinal Year Report, British Gas Report (1995). McColvin, G. M., "Commercially-Available Alloys—IronBase Alloys," Presented at AEA Technologies Workshop on ODS Alloys, Risley, England, March 1995. McColvin, G. M., and Smith, G. D., "Environmental Resistance of Incoloy Alloy MA956," pp. 139-153 in High-Temperature Alloys, J. B. Marriott et al., Eds., Elsevier, New York (1987). Natesan, K., Freeman, Ni, and Mathur, M., "Corrosion Performance of Materials for Advanced Combustion Systems," Presented at the Ninth Annual Conference on Fossil Energy Materials, Oak Ridge, Tennessee, May 1995. Opila, E. J., and Jacobson, N. S., "Volatile Hydroxide Species of Common Protective Oxides and Their Role in High-Temperature Corrosion," Presented at the ECS Symp. on Fundamental Aspects of Corrosion VI, San Antonio, Texas, Oct 1996 Plumley, A. L., Accortt, J. I., and Roczniak, W. It, "Evaluation of Boiler Tube Materials for Advanced Power Cycles," pp. 623-679 in Proc. Conf on Corrosion/Erosion of Coal Conversion System Materials, A. V. Levy, Ed., NACE (1979). Quadalckers, W. J., Bongartz, K., Schubert, F., and Schuster, H., pp. 1533-1542 in Materials for Advanced Power Engineering 1994, D. Coutsouradis, et al., Eds., Kluwer Academic Publishers (1994). Robson, F. L., Ruby, J., and Seery, D. J., "Repowering with High-Performance Power Plant Systems (HIPPS)," pp. 162-167 in Proc. Pittsburgh Coal Conf., Sep. 1996. Ruth. L. A., and Birks, N., "Materials Needs for HighEfficiency Coal-Fired Power Plants, " Proc. Intl. Symp. on UltraHigh-Temperature Materials, Tajimi, Japan, Dec. 1995; in print Solomon, T. R., Serio, M. A., Cosgrove, J. E., Pines, D. S., Zhao, Y., Buggeln, It C., and Shamroth, S. J., "A Coal-Fired Heat Exchanger for an Externally-Fired Gas Turbine," Trans. ASME, Engg, for Gas Turbines and Power 11 8, 22-31(1996). Sporer, D. "Designing with MA-ODS Materials," Presented at AEA Technologies Workshop on ODS Alloys, Risley, England, March 1995. Starr, F., White, A. E., and Kazimierzak, B., "Pressurized Heat Exchangers for 1100°C Operation Using ODS Alloys, Pp. 13931412 in Materials for Advanced Power Engineering, 1994, D. Coutsouradis, et al., Eds., Kluwer Academic Publishers (1994). Stringer, J., and Wright, I. G., "Current Limitations of HighTemperature Alloys in Practical Applications," ardtn. Metals, 14 (1/2), 265-308 (1995). Swindeman, R. W., and Marriott, D. L., "Criteria for Design With Structural Materials in Combined-Cycle Applications Above 815°C," Trans. ASME, J. for Gas Turbines and Power 116, 3 52359 (1994). Tamura, M., Yamanouchi, N., Tanimura, M., and Minami, Y., "High-Temperature Performance of 35Cr-45Ni-Fe Alloy," pp. 389403 in High-Temperature Corrosion in Energy Systems, M. F. Rothman, Ed., The Metallurgical Society of AIME (1985). Thomas, W., Nicolas, D., and Jones, S., "Third-Body Friction Joining," Connect—The Welding Institute Research and Development publication, April 1994. 10 Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 12/29/2014 Terms of Use: http://asme.org/terms APPENDIX 1: WORKING FLUID CONSIDERATIONS Wallach, R., "Joining MA-ODS Materials," Presented at AEA Technologies Workshop on ODS Alloys, Risley, England, March 1995. Wereszczalc, A. A., and Kirkland, T. P., "Creep Performance of Candidate SiC and Si3N4 Materials for Land-Based Gas Turbine Components," ASME paper No. 96-01-385, Presented at the Intl. Lee et al. (1980) compared the pertinent properties of potential working fluids and chose helium, helium/carbon dioxide (0.6 He/0.4 CO2 by mole), and air as candidates for a closed-cycle application similar to that considered here. Under the conditions considered, the heat transfer coefficients for the these three candidate working fluids were in the order: 1.0 : 0.87 : 0.52, respectively, indicating that with air a larger temperature drop would be experienced across the heat exchanger wall (and a significantly larger surface area would be needed) for the same duty. Lee et al. (1980) also showed that the heat transfer coefficient in a coal-fired, closed cycle system varied as the 0.6 power of the working fluid pressure, so that increasing the total operating pressure will reduce the tube wall temperature and the amount of surface area required. Gas Turbine and Aeroengine Congress and Exhibition, Birmingham, England, June 1996. Yoshimura, Y., ltoh, K., Ohhori, K., Hori, M., Hattori, M., Yoshida, T., and Watanabe, K., "Development of Shell and TubeType Ceramic Heat Exchanger for C01301," ASME paper No. 95GT-208, Presented at the Intl. Gas Turbine and Aeroengine Congress and Exposition, Houston, Texas, June 1995. 11 Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 12/29/2014 Terms of Use: http://asme.org/terms

© Copyright 2026