Doorking 9210 Quickstart

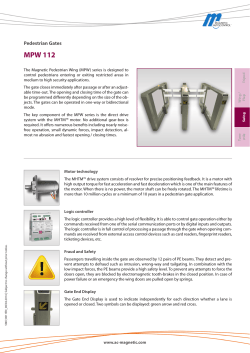

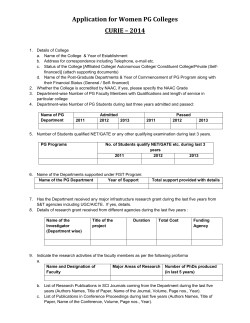

QUICKSTART “BASIC” GUIDELINES FOR MODEL 9200 “FULL OPEN”: MOUNTED DIRECTLY ON A CONCRETE PAD Limit Switches V W PE PE A Hot 115 VAC Output 115 VAC SINGLE Phase White - Neutral Black - 115 VAC Hot Green - Chassis Ground High Voltage AC Input Wire 208/230 VAC SINGLE Phase Use only two legs of the incoming 3-phase power. Check polarity of Three Phase: Hot Hot Position the gate half way open. Give open command and while gate is opening, activate the appropriate limit switch with your finger. Gate should STOP. If it does Chassis not, activate the other limit switch. Ground If this STOPS the gate, AC power High wires must be changed (Reverse Voltage the connection of any 2 wires and AC Input re-check limits). Wire Hot A 115 VAC Output 208/230 VAC THREE Phase DIP-Switches B SW 1 and 2 are Upside-Down on Circuit Board. SW 2 SW 1 D 1 23 Adjust 1 to 23 sec. C Plug-In Loop Detectors See reverse side to wire main terminal. 20 19 18 17 16 15 14 13 12 11 10 9 High Voltage AC Input Wire 1. Opening Direction 2. ON 3. ON 4. OFF 5. OFF TIME 6. OFF DELAY 7. OFF 8. OFF B Chassis Ground VERIFY Input AC power MATCHES your specific operator power BEFORE wiring! See reverse side TIME DELAY Copyright 2013 DoorKing, Inc. All rights reserved. D NC Limit Assembly Guard 3/4”conduit with sweeps recommended. Attach operator to concrete pad with twelve (12) 1/2” x 3” sleeve anchors (not supplied) after concrete pad has been poured and has cured. Hot Auto-Close Timer NO Concrete Pad 14” 1A 2A Limit LEDs REV SENSE CLOSE 14” 1/2 1 2 4404-010 A 1. OFF 2. OFF 3. OFF 4. OFF Chain Knock-out Chain Bracket Chassis Ground 9410 Plug-In Loop Detector EXIT LOOP Chain brackets MUST be mounted so the chain remains the same height as it is on the idler wheels! 9410 Plug-In Loop Detector LMT T Chain Configuration With power OFF, push and hold the lock plate down where shown to adjust the Open and Close limit nuts. After adjusting the limit-nuts, be sure that the lock-plate is engaged in the slots on the limit-nuts to prevent them from rotating. The slow-down limits on all models but the 9210 will move up or down 3/4 inch. DO NOT remove the slow-down limit assembly from the 3/4 inch slot and re-attach it in the longer slot on the partial open adjustment rail to gain further adjustment. This will cause mechanical damage to the switch assembly when the operator is activated. Turn power ON and activate the gate operator. Re-adjust the limit nuts as necessary for full-open and full-close gate travel. After you are satisfied with the gate limit settings, the speed control knob can then be adjusted on all models but the 9210 to personal preference. REV SENSE OPEN Pad depth is determined by soil conditions and local building codes. Minimum depth is 18 inches. Reinforced concrete recommended. U 2 ft/s LOOP 4” Min. Above Ground Wire Mesh 1.5 ft/s 0 ft/s Concrete pad MUST be level! Idler Wheels 14” basic I/O control P7 14” SCM series 1 ft/s P6 Side View Speed Control Knob REVERSE knock-outs from operator housing. Speed Controller On all models but 9210. P8 Idler wheels are factory set in the correct Remove the chain position. 1.0 EPM Mode .5 ft/s B- B+ PE 17 Gate Frame Operator Housing Chain nut and chain bolt should not protrude past gate frame. The chain should sag no more than one (1) inch per 10 feet of travel. Do not over tighten the chain. L1 L2/N Min Max Speed 28” Chain Bolt cycle the operator until the “DIP-Switches” and the “Limit Switches” have been adjusted. Damage could occur to the gate and operator. Chain brackets MUST align with idler wheels so chain stays parallel to gate! Neu 115 VAC Output DO NOT power up and 4” Concrete Pad k in rL ste Ma 4” Hot 1 2 3 4 Chain Nut Operator Base Plate Tip: It is recommended that a surge suppressor be installed on the high voltage power lines. High Voltage AC input power MUST MATCH the operator specifications or DAMAGE will occur and VOID the warranty! ON n2 tio 23” 2A Chassis Ground GATE OPERATOR MUST BE PROPERLY GROUNDED!! Anti-Grounding Plate 1 2 3 4 5 6 7 8 n1 Conduit Area it im 2 Litch Sw 115 VAC Convenience Outlets A ON Top View Conduit Area C Chain Bracket Idler Wheels Conduit Area Opening direction using ON setting. Push Chain Bracket Op 1” 1” tio sed tU No Limit Nut Gate Op en Op Operator MUST be parallel to gate! Opening direction using OFF setting. Connect Chain to Gate Pa High Voltage Connection DANGER HIGH VOLTAGE! CAUTION Slow-Down Limit C l rtia Remove the 3 locknuts inside the electronic box to swing box open. P7 Remove the limit assembly guard. Conduit suggestions: • High voltage conduit • Low voltage access control device conduit • Reverse loop conduit • Automatic exit loop conduit 1A Push Gain Access Inside Operator 20” Pedestrians must be supplied with a separate access opening. For safety and installation instructions, please refer to the Installation/Owner’s manual. P6 it im 1 Litch Sw Model 9200 is intended for installation only on sliding gates used for vehicles. 10 4-0 440 Lock-Plate 3 Never attempt to manually operate the 9200 until you have verified that power has been shut-off. Partial Open Adjustment Rail it ndu t Co Cutou 2 Caution: Limit Nut ” te pla em ided T ite ov son t Pr Ma No ox 1 18 it ndu t Co Cutou t i ndu t Co Cutou cB 16 GA TE Oper INJ CA and ate UR N free gate Y ORCA of only Do peop whe US or not allow le DE E andn gate oper AT obst area ate child H Do gate ren ructi is ons.in sigh pathnot stan . to play whil d t in in e gate gate gate Read area is path own mov er’s ing.or walk man thro ual ugh and safe ty instr uctio ns. 1 2 5 6 11 13A 13B 13E 25 MO SE VIN RIO G US P8 CA Electronic Box Hz Clear Plastic Electronic Box Cover 60 Slow-Down Limit Tip: Trace the base plate of the operator on a piece of masonite (Not provided) and make a template to help locate where the conduit runs will be positioned in the concrete pad. SE D Inc. , Ingl ewo od, REV SENSE CLOSE g, ON PHA E LOA rKin ON GAT U.S.A. LMT S Doo Ma cranual stonk in po red siti on . EXIT LOOP G ERA TOR HP VOL TS AMP MAX oni REVERSE NIN E OP MOD EL SER IAL ctr WA R 120 Glasgow Avenue Inglewood, California 90301 Power safety and opening devices that require 115 VAC power. LOOP 53382 3 4 3 4 3 4 Ele CON ANSFOR I/ULMS TO -325 CAN CER /CSA TIFI C22ED TO VEH ICU .2 NO. CLA LAR 247 SS GAT Two 115 VAC Convenience Outlets 2 1 2 1 2 1 1 2 3 4 AccManua ess l C Pan rank el 1 2 3 4 5 6 7 8 All 9200 Models: DoorKing highly recommends using the pedestal mounting stand for gates heavier than 2000 lbs. for a more secure attachment to a larger and heavier concrete pad. 8 7 6 5 4 3 2 1 Not included - Refer to the Installation/Owner’s manual AND Loop Information Manual (available from www.dkaccess.com) for more information on loops and plug-in loop detectors. Important Note: DoorKing highly recommends that loops and loop detectors are installed with this slide gate operator. A loop detection system will preventing the gate from automatically opening or closing on a vehicle when it is in the gate’s path. 9210-066-E-2-13 QUICKSTART “BASIC” GUIDELINES FOR MODEL 9200 - DIP-SWITCH AND WIRING REFERENCE Model 9200 is intended for installation only on sliding gates used for vehicles. Pedestrians must be supplied with a separate access opening. For safety and installation instructions, please refer to the Installation/Owner’s manual. Main Terminal SW 1 DIP-Switches (Right Hand Side) Setting Description NO Function SW 1 - Right 8 Switches U.S.A. P7 Switch 120 Glasgow Avenue Inglewood, California 90301 NC Auxiliary Common Terminal Changes the direction the operator will open/close the gate. 1 Opening direction using OFF setting. Opening direction using ON setting. 20 19 18 17 16 15 14 13 12 11 10 9 Connect any common wire to these 2 terminals. 8 7 6 5 4 3 Relay activates and LED is ON when the gate is fully open. Relay activates and LED is ON when the gate is not closed. Relay activates and LED is ON when the gate is opening and open. Relay activates and LED is ON when the gate is opening and closing. Relay Activation 4-OFF 5-OFF and 4-OFF 5-ON 4 and 5 LED Indicator 4-ON 5-OFF Light Activation 4-ON 5-ON OFF Normal Setting. No sound. Warn Before 6 Operate ON Internal alarm will sound before gate starts and throughout gate’s cycle. Reverses Gate Stops Gate 8 Quick-Close Timer Override OFF Normal Setting. Input to terminal #6 and/or reverse loops will REVERSE gate during CLOSE cycle. ON Input to terminal #6 and/or reverse loops will STOP gate during CLOSE cycle. OFF Normal Setting. Timer will function normally. ON Opening gate will stop and begin to close as soon as all reversing inputs (Reverse loops, photo sensors) are cleared regardless of the distance the gate has opened. SW 2 DIP-Switches (Left Hand Side) 1 2 3 4 ON SW 2 Switch Function 1 Self-Test 2 Gate Opens Uphill 3 Gate Opens Downhill 4 Spare Upside-Down on Circuit Board. Setting OFF ON OFF ON OFF ON White Com 3-Button Control Station DoorKing ONLY SW 1 is Upside-Down on Board SW 1, Switch 3 MUST be ON except for dual operators or exit loop partial open applications. Important: Controls must be far enough from the gate so that the user is prevented from coming in contact with the gate while operating the controls. Outdoor or easily accessible controls should have a security feature to prevent unauthorized use. Telephone Entry “Optional” REVERSE GATE for Closing Direction Photo Sensors Note: After a DIP-switch setting is changed, power must be turned OFF and then turned back on for the new setting to take affect. Functions ONLY during gate closing cycle. Key Switch #1-Com #2-Fully opens gate. Safety Opening Device #1-Com #2 or #5-Relay #3-24 volt 250 mamp. max. 3-Wire Radio Receiver #1-24 Volt Power Com #1-Relay Com #2 or #5-Relay #3-24 Volt Power 4-Wire Radio Receiver ON ON 7 Green Close 1 2 3 4 5 6 7 8 Full Open Input Jumper Wire Needed See Manual Red Full Open Note: All stand-alone and telephone entry devices must use a separate power source. ON 3 Exit Loop Port Output OFF Auto-close timer is OFF. Manual input required to close gate. ON Auto-close timer is ON. Adjustable from 1-23 seconds to close gate. OFF The output wired to terminal #4 becomes the output from the loop detector installed in the EXIT loop port. Plug-in loop detector required for “OFF” function. ON Normal Setting. Terminal #4 is a normal full open input for a single gate operator. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 Upside-Down on Circuit Board. Auto-Close Timer #4 - Full Open SW 1 2 #5 - Partial Open (See manual) Factory Set Configuration 2 1 SW 1 is Upside-Down on Board SW 1, switch 7: After photo sensor beam gets obstructed: OFF Setting - REVERSES GATE. ON Setting - Stops gate then continues closing when gate is clear (Same function as UL 325 terminal #2). Note: The ON setting is used to help prevent tailgating but the photo sensor should be wired to the UL 325 terminal #2 when the “stop gate” function is desired, see manual for more information. SW 2 - Left 4 Switches Description Normal Setting. Normal gate operation. Self-test mode. Operator MUST be disconnected from gate to run self-test. Normal Setting. Normal gate operation. MUST be ON if gate opens UPHILL. Normal Setting. Normal gate operation. MUST be ON if gate opens DOWNHILL. OFF Leave in the OFF position. Stand-Alone Keypad Com Stand-Alone Card Reader To #4 or #5 #5 Terminal Note: Any opening device connected to terminal #5 will open the gate to the partial open setting. Secondary entrapment protection devices will also open the gate to the partial open setting. If the Inherent Reverse Sensor gets activated during the close cycle, it will always fully open the gate.

© Copyright 2026