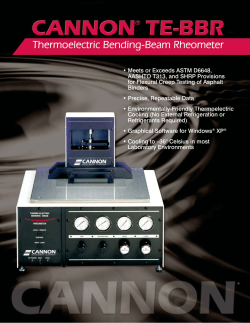

PDF - Hot