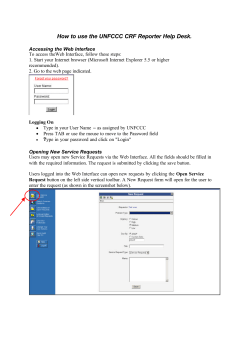

SheetCam Operator Manual v5