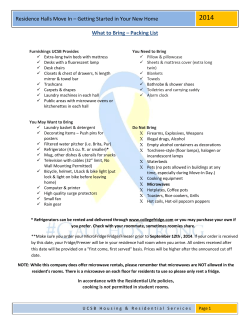

Microwave food processing_review