Sales Brochure - Apex Advanced Technologies, LLC

Find out what your '

competitors already

l{now...

General SUDlDlary

Apex Superlube®

•

Predictable

•

Excell~nt ejection and green strength

•

Proprietary database of metal compressibility

with ideal lubrication

mal{es you money

Iinprove Your Profitability

density and lubrication

Appli~ation

Significantly reduce tool wear

Scrap rates reduced in pressing and sintering

Improved furnace throughput. ..

like buying capacity

Reduction in press tonnage ...

less new capital needed

Inerease Your Sales and Margins

Higher green and sintered densities allow you to

compete for new and high margin products.

Increased physical properties allow for substitution of other metal shaping techniques

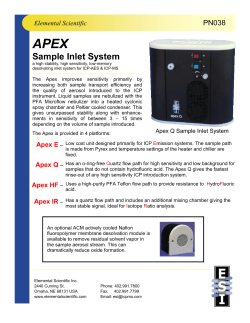

APEX

needs

ADVANCED TECHNOLOGIES,

Slale of Ihe Al'l Luhricants

Apex

Superlube®

SUDlDlary

•

Full density range, up to 7.4g/cc

•

Elimination

of double press/double sinter

•

Elimination

of cracks in parts, up to 7.4g/cc

•

Minimization of ejection problems, up to 7.4g/ cc

•

Minimization of die wear, up to 7.4g/cc

•

Highly efficient/cost effective copper infiltration

•

Elimination of cracking and blistering with high

nickel formulations.

Let It Make Money For Yon

Technology Base

Apex Superlube®

Apex Enhancer 51

Custom Superlube®jgraphite mixes

Flow Enhanced Superlube®jgraphite mixes

Enhanced Flow Enhancer 51

Master Batch Superlube®jcustom

\

Eas,' To Use

\

II

ADVANCED

TECHNOLOGIES,

(5.5., Low alloy, Malleable iron, AI, Cu)

LLC

U.S. Sales Representatives for Apex Advanced Technologies

Graphite Master Batch makes mixing a breeze

I

\ I'",,\,hall('('d

\llt~g-hell~ CoatiJl.~::-;

Apex Enhancer ST to facilitate use at all

density ranges,

:2~1 Hi\'el'

HO(ltL I-iid~e'ray~

p.\

nll.77:2.:)[L,)()

W\\"\,.

additives

(Fe3P, Bi, Mn, Si, V)

Agglomerated Spherical gas atomized high alloys

(Cr, Ni, Co)

Near Full density activation technology

APEX

I

LLC

and Bind(~rs

~\

J1('glit'lIyCnal

illg-~.COHl

T('chllolo;!i"" LLC

If):),- \ \\1',1 HOth SireI'I

C!"\ (·Ialld. Ohio III :\,";-.)In2

Pho.l<': 216.B9B.I.)'):)

Fax:

21 ().B9B.:)66 I

www.apexadvancedtechnologies.com

I

Apex Superlnbe®IEnhan~er ST

State of the Art Lnbri~ant and Binders for the P 1M Industry

Density < 6.9~/~~

Density > 6.9 to 7.1 fi./~~

Density > 7.1fi./~~

Apex Enhan~er ST

Apex Snperlnbe®

Apex Enhan~er ST

Apex Snperlnbe®

Apex Enhan~er ST

Fixed Additions

Calculated Additions

Excellent Green Strength

Excellent Lubricity

Minimization

Excellent Lubricity

Minimization

Elimination

of die wear

of Zinc-based lubricants

of cracking

Minimization

of chipping

Handling defects

Environmentally

friendly

of die wear

Excellent Green Strength

Up to 50% reduction in ejection forces

Good compressibility

Minimization

Calculated Additions/Low use levels::::;0.4%

Effective copper infiltration

Elimination

of blistering with nickel formulations

Elimination

of Zinc-based lubricants

Clean burn/Environmentally

Large part capability-up

Enhancer ST for volume adjustments

Green Density results comparable to die wall, hot

compaction, warm compaction or double pressing

Physical properties improved as much as 15-20%

Elimination of Density Gradients

Dimensional stability and resulting

scrap rates improved

Excellent Lubricity

Minimization of die wear

Excellent Green Strength

Increased compressibility

Up to 25% reduction in compression forces

Densities up to 7.4g/cc

Effective copper infiltration

Elimination of blistering with nickel formulatiom

Elimination of double pressings

Clean burn/Environmentally

friendly

Large part capability-up

to 9 lbs.

friendly

to 9 lbs.

Efficient for Iron, Stainless Steel and

Copper based alloy

Part temperature needs to be a minimum 1200 F

to maximum 1800 F to function correctly

APEX

Apex

Superlube®

Let It Make Money For Yau

ADVANCED TECHNOLOGIES,

State

of the Art

Lub!"ieallts

and

LLC

Billdt>!"s

Superlube® is a registered

trademark of

Apex Advanced Technologies LLC.

Patents #6,679,935 & #7,183,242

© Copyright 2026