AVEVA NET Portal

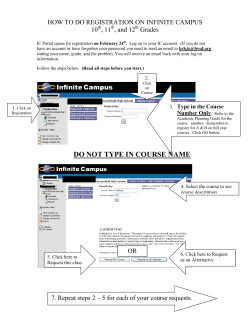

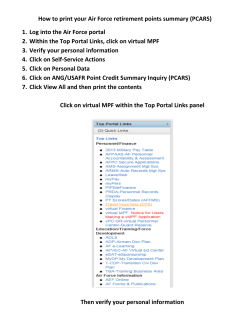

AVEVA NET Portal 3.6 for Plant Operations Unlock plant and process information silos – create stable, safe operations across your plant AVEVA’s solutions for Owner Operators are powered by our AVEVA NET technology, an application-neutral environment for operational, maintenance and safety data, no matter which program created it, or how it is stored. AVEVA NET is a powerful platform for making this data available and useful to a wide range of users, applications and work processes, across all lifecycle phases. AVEVA NET makes data available where and when it is required. Built on this platform, AVEVA NET Portal is an Information Management solution that brings together information from diverse applications and data sources, and provides a unified, web-based, digital profile of the physical plant that can be shared easily across offices and territories. Business Benefits Summary: • Minimise downtime. AVEVA NET Portal empowers operations and maintenance personnel to minimise unplanned downtime. • Health, Safety and Environment (HSE). AVEVA NET integrates safety-related information to mitigate HSE-related risks by providing rapid and easy access to current information, irrespective of its source or location. • Improve staff productivity. AVEVA NET Portal's highly intuitive interface enables rapid access to unlimited information sources, resulting in considerable man-hour savings and improved efficiency. Wherever in the world you or your team are, AVEVA NET Portal gives straightforward web access to operational information, in multiple formats and from multiple sources. Here, real-time instrumentation information is combined with photographic information and electronic documents to give a truly comprehensive picture of a particular pump PLANT www.aveva.com Business Benefits (continued) Key Features Minimise downtime Automatically, intelligently linked data 5% of total production is lost each year due to unscheduled downtime Information can be imported from a very wide variety of systems through gateways, as described below. However, the unique advantage of the AVEVA NET technology is that, when this data is loaded into the portal, it is intelligently and automatically linked. With alternative solutions, these links have to be made manually, which means that they cannot be easily kept up to date without a major investment in manpower. AVEVA NET Portal empowers operations and maintenance personnel to minimise unplanned downtime, by providing: • Rapid access to operating information, manuals and instructions • Access to plant information in support of shift handovers Open and flexible for changing business needs • Rapid access to datasheets, drawings, schematics, maintenance instructions, manuals and spare parts information The direct benefits include: AVEVA NET Portal is an open, highly configurable solution that can be rapidly deployed and tailored to complement an organisation's existing work processes and systems. It is extremely flexible since, unlike alternative solutions, all the information hierarchies and associations that the system presents are stored as data. This means that the system structure and functionality can be easily changed during the life of a product as new demands for information become apparent. • Reduced plant trip-outs, upsets and abnormal operation Rapid access to plant information through an intuitive web interface • Access to information to support plant commissioning and start-up • Access to information to support operations and maintenance training • Reduced time to repair plant and equipment • Reduced commissioning and start-up times following shutdowns Health, Safety and Environment (HSE) Lack of information sharing is the largest attributed cause of safety incidents AVEVA NET integrates safety-related information to mitigate HSErelated risks by providing rapid and easy access to current information, irrespective of its source or location, supporting: • Incident investigation and analysis • Safety instructions and procedures • Change Management • Regulatory reviews • Plant safety design walkthroughs • Emergency control centre information • Emergency response planning, training and exercises • Identification of plant safety equipment locations Improve staff productivity Up to 60% of all equipment downtime can be attributed to delays in finding the correct information AVEVA NET Portal's highly intuitive interface enables rapid access to unlimited information sources, resulting in considerable man-hour savings and improved efficiency in: • Collaborating with internal and external colleagues, contractors, third-party organisations and specialists • Compiling work permits and work orders • Compiling and issuing work packs for maintenance and shutdown/turnaround work • Accessing information for maintenance and inspection regimes • Accessing information for regulatory reviews and inspections • Accessing and compiling information for HAZOP and change management reviews • Accessing information for incident investigation and analysis Simple searches allow rapid information retrieval, whilst the automated linking of information sources enables fast navigation between document types. So, if P&IDs are being used to conduct a HAZOP review, all other associated information can be easily retrieved from 3D models, datasheets, process information, plot plans, general arrangements, and so on, by simply clicking on the intelligent hotspots within the P&ID and navigating around the plant data. Data consistency and data completeness checks An intuitive, easy-to-use search and query facility enables the loaded information to be analysed to detect 'data clashes' where, for example, two documents have different values for an attribute in a tagged item. Reports of data completeness can also be carried out to highlight missing attributes in the loaded data. These two facilities enable inconsistencies and gaps in data to be highlighted to assist in data validation and quality assurance of the plant data. Arrangement drawings Datasheets Equipment lists P&IDs As-built data Visualisation of 3D model with real time operational data and links to all related information accessible from a single page. Maintenance Plans Purchase and delivery status Real time data from DCS systems Collate information in context and collaborate locally and globally Access to real-time and historic plant process information AVEVA NET Portal allows information to be collated for review with third parties, either online or via email. For example, information can first be collected into the work packages needed to support the desired activity, such as maintenance, commissioning and start-up, safety review and audits. The information can then be interactively reviewed and annotated with comments and mark-ups by participants in the review process. AVEVA NET Portal enables real-time plant operational data to be accessed by simple reference to tag or equipment numbers. This information can be displayed in custom web forms, on P&IDs, in 3D models or on any other document of interest, enabling process conditions to be viewed in the context of the issue being addressed. Key Features (continued) Access plant information through 'intelligent' as-built data AVEVA NET enables plant models consisting of photographs and laser scan data to be used for navigating or accessing plant information by simply clicking on tag or equipment numbers within the photographs and /or laser scan images. This is achieved by overlaying the photographs and /or laser scan images with 'intelligent' links that reference all related plant information. Standard Gateways and Data Exchange AVEVA NET Portal connects to data sources and applications via gateways that conform to international standards (ISO 15926 and ISO 10303), eliminating any dependency on supplier systems, and future-proofing the investment. Gateways are available for a comprehensive range of systems and applications (including Intergraph, Bentley, SAP and MRO) and bespoke gateways can be developed to meet specific customer needs. AVEVA NET Portal is the only true low-risk Information Management solution, having been proven in 24x7 operations on some of the world's largest and most complex process plants. Engineering Domain Operations & Maintenance Domain ERP/CMM Maintenance and planning systems DAD Line List, Datasheets 3D CAD EDMS Intelligent P&IDs Engineering 2D/3D Management Workbench LIMs Laboratory systems DCS/SCADA LMI/ Photogrammetry Instrument Documents and drawing management Production systems Data Historians AVEVA NET Portal AVEVA NET Portal supports the management of the engineering data lifecycle, allowing integration of new projects and existing assets into a single operations portal AVEVA believes the information in this publication is correct as of its publication date. As part of continued product development, such information is subject to change without prior notice and is related to the current software release. AVEVA is not responsible for any inadvertent errors. All product names mentioned are the trademarks of their respective holders. © Copyright 2008 AVEVA Group plc. All rights reserved. NET/OO/DS/08a PLANT AVEVA Group plc High Cross Madingley Road Cambridge CB3 0HB UK Tel +44 (0)1223 556655 Fax +44 (0)1223 556666 www.aveva.com

© Copyright 2026