Understanding that the numbers of ... sector are still limited and ...

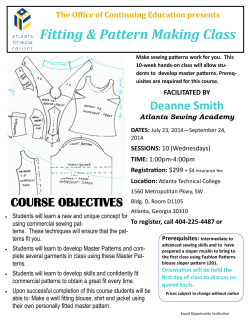

Understanding that the numbers of local technician for garment and footwear sector are still limited and not yet responding the great demand of industry, GMAC- Garment Manufacturers Association in Cambodia has cooperated with the national and the international training providers to bring the experts to provide training for both hard skill and soft skill in order to train new people who wish to work for the industry and to upgrade the skills levels of employees, workers who already employed by garment and footwear factories. By the end of December 2013, 11 courses were conducted with 346 trainees. 44 trainees graduated from the pattern making training while 249 were successfully completed the Labor training on New Minimum Wage and Employment Contract; and other 53 trainees completed the training on Health Care and Occupational safety and Health in the Workplace conducted by CBCA. Table shows all training courses in 2013 Courses Name Seminar on Minimum Wage Labor training – Employment Contract Health Care and Occupational Safety and Health in the Workplace Pattern making on Dress with Lining Pattern Making on Blouse Pattern Making on Woman Pants Pattern Making on Woman Jacket No. of Course Course Duration 1 4h Venue Phnom Penh Hotel’s conference room 3 8h GMAC’s conference room 3 8h 1 90h GMAC’s conference room GMAC’s training room 1 60h 1 84h 1 96h Training Program for 2014 No. of Traine e 165 Trainee From GMAC’s members -Mr.Cheat Khemara 84 GMAC’s members 53 GMAC’s members -Mr. Cheat Khemara Mr. Soung Hourth -Mr. Chon Bora CBCA 13 GMAC’s members and Public GMAC’s members and Public -Mr. Mizuno JP expert -Mrs. Hin Sopheap -Assisted by JP expert -Ms. Kong Chanmarady -Assisted by JP expert GMA’s training room 11 GMA’s training room 10 GMAC’s members and Public 10 GMAC’s members and Public GMA’s training room Trainers Name -Ms. Kong Chanmarady -Assisted by JP expert From time to time, GMAC’s trainer team and the international experts have worked closely with the members of GMAC in order to understand the most needed skills by the industry. There are 12 of training courses to be conducted and 153 trainees to be trained in 2014. Table shows numbers of training course and number of trainee to be trained in 2014 No. Course Name 1 Pattern Making on Blouses Pattern Making on Women Pants Sewing Skill 2 3 4 5 Production Supervisor Sewing Machines Seminar Total Course Duration 60 h Number of Course 2 courses Number of Trainee 24p 60h 2course s 24p 60h 3courses 30p 48h 3courses 45p 18h 2courses 30p 12 courses 153p Please find attached file for each course detail. Attachment No.1 Attachment No.2 Attachment No.3 Attachment No.4 For more information please do not hesitate to contact Mr. Tim Savann, Sr. Trainer at 023 88 34 35; Email: [email protected] or [email protected] The whole year training program for 2014 Attachment No. 1 Course Details 1. Name of institution/provider 2. Training course title 3. Objectives of the training course GMAC Pattern Making on Blouses (Basic Level) To know the whole process of blouses making which include pattern drawing on paper, fabric cutting, Ironing and assembling (sewing) 4. Requirement High school or higher 5. Target audience Cambodian Pattern maker Person who wants to be pattern maker 6. Course content - Fashion Drawing: To know the basic of fashion drawing through all elements. - Measurement: To measure the body (size, length) accurately - Drafting: To construct block pattern and pattern adaptation to develop your own style. - Lay Planning: To lay out the pattern on your chosen fabric and cutting - Assembly: Basic sewing and assembly instruction - Finishing: Ironing, hand sewing and will be instructed 7. Duration 60 hours 8. Schedule/Dates/ time 2nd -13rd June 2014 4th -15th August 2014 9 Language Khmer 10. Location of the course Garment Manufacturers Association in Cambodia No.175 Jawaharlal Nehru Blvd (Street 215) Phnom Penh, Kingdom of Cambodia 11. Equipment required / Learning Materials 12. Course fee (and what it includes 13. Outcome – gain competence/ skills To be provided US$ 70 Know how to use pattern cutting equipment. Create a blouse block. Create pocket patterns. Create a basic blouse pattern. Produce a range of pattern samples for future reference. Demonstrate pattern cutting techniques used in the making up of a basic blouse pattern. Able to sew/assemble Blouse 14. Diploma/Certificate offered Certificate (trainee who passed both attendance and competency) 15. More info/contact Register at : E-mail: [email protected] [email protected] Tele : +855 23 88 34 35 Fax : +855 23 88 28 60 URL : www.gmac-cambodia.org Attachment No.2 Course Details 1. Name of institution/provider 2. Training course title 3. Objectives of the training course GMAC Pattern Making on Pants (Basic Level) To know the whole process of Women pants making which include pattern drawing on paper, fabric cutting, Ironing and assembling (sewing) 4. Requirement High school or higher 5. Target audience Cambodian Pattern maker Person who wants to be pattern maker 6. Course content - Fashion Drawing: To know the basic of fashion drawing through all elements. - Measurement: To measure the body (size, length) accurately - Drafting: To construct block pattern and pattern adaptation to develop your own style. - Lay Planning: To lay out the pattern on your chosen fabric and cutting - Assembly: Basic sewing and assembly instruction - Finishing: Ironing, hand sewing and will be instructed 7. Duration 60 hours 8. Schedule/Dates/ time 16th -28th June 2014 18th -29th August 2014 9 Language Khmer 10. Location of the course Garment Manufacturers Association in Cambodia No.175 Jawaharlal Nehru Blvd (Street 215) Phnom Penh, Kingdom of Cambodia 11. Equipment required / Learning Materials 12. Course fee (and what it includes 13. Outcome – gain competence/ skills To be provided US$ 70 Know how to use pattern cutting equipment. Create a pants block. Create pocket patterns. Create a basic pants pattern. Produce a range of pattern samples for future reference. Demonstrate pattern cutting techniques used in the making up of a basic pants pattern. Able to sew/assemble pants 14. Diploma/Certificate offered Certificate (trainee who passed both attendance and competency) 15. More info/contact Register at : E-mail: [email protected] [email protected] Tele : +855 23 88 34 35 Fax : +855 23 88 28 60 URL : www.gmac-cambodia.org Attachment No.3 Course Detail 1. Name of institution/provider 2. Training course title GMAC Sewing Operation (Sewing for operator) Providing a right sewing skill for sewer Increase manpower for garment industry sector Supporting to poor people and family 4. Requirement The student must be assessed for eyesight and hand coordination. 5. Target audience Unemployed individuals without sewing skills. Good eyesight, hand coordination and no color blindness. New worker 3. Objectives of the training course 6. Course content 1-Step one: Preparation sewing machine Operate and thread lockstitch sewing machine Operate and thread overlook sewing machine Carry out vertical, curve and horizontal stitching 2- Step two: Sewing Preparation Prepare Sleeves Prepare Pockets Prepare Lower Part of Front Bodice Sew Square Patch Complete Front Prepare Label Attach Yoke Patch 3- Step three: Sewing Preparation Prepare Back Bodice Join Shoulder Set Sleeve Join side seam and sew shirt hem Attach Rib to neck hole and Sleeve Hem Reinstate workstation 7. Duration 70 hours 8. Schedule/Dates 10th -21st March 2014 07th -23rd April 2014 08th -19 September 2014 9 Language Khmer 10. Location of the course Garment Manufacturers Association in Cambodia 11. Equipment required No.175 Jawaharlal Nehru Blvd (Street 215) Phnom Penh, Kingdom of Cambodia All learning materials will be provided 12. Course fee (and what it includes USD50.00 13. Outcome – gain competence/ skills (Include all learning Materials) The students will know “How to live safely in city” Be able to do basic of communication and know how the garment factory work like Understanding basic of labour-law Understanding the advantage of good team work At the end of the training program, the student should have achieved the following capabilities and be able to start as a sewing operator in any garment factory. Perform simple sewing parts of Polo shirt and man shirt. Be able to do basic maintenances of sewing machine. 14. Diploma/Certificate offered Certificate (trainee who passed both attendance and competency) 15. More info/contact Register at : E-mail: [email protected] [email protected] Tele : +855 23 883435 Fax : +855 23 88 28 60 URL : www.gmac-cambodia.org Attachment No. 4 Course Detail 1. Name of institution/provider 2. Training course title 3. Objectives of the training course GMAC Supervisor Course- for supervisors and line leaders To equip participants with the fundamental principles and tools in operation analysis, time and motion study, and line balancing. To do a time and motion study in the factory. To be able to trouble shoot on existing production lines, identify problems and improve productivity. To design and efficient production layout. High school or higher At least 1 year work experience in production line. 5. Target audience Potential future supervisor, line leader, supervisor, Industrial Engineering, and public (with similar know ledges). 6. Course content Production rationalization and role of management Process Analysis Operation analysis Time Study Motion Study Production Design 36 hours (classroom) 12 hours (factory) 19th -30th May 2014 14th –25th July 2014 17th -28th November 2014 9 Language Khmer 10. Location of the course Garment Manufacturers Association in Cambodia 11. Equipment required No.175 Jawaharlal Nehru Blvd (Street 215) Phnom Penh, Kingdom of Cambodia (Subject to prior arrangement, training can be conducted in respective GMAC member factory). All learning materials will be provided 12. Course fee (and what it includes USD70.00 4. Requirement 7. Duration 8. Schedule/Dates 13. Outcome – gain competence/ skills (include learning materials) Be able to place the right men to the right jobs and manage production lines. 14. Diploma/Certificate offered 15. More info/contact Analysis the actual state of production activities. Standardize method of production flow chart. Understand factory condition and workers behavior. Identify problem in factory. Calculate the allowance rate and operation rate Identify cycle time for each process. To determine process time for each operation. Comprehend the principles of KAIZEN Identify wasted or inefficient motions. Comprehend motion economy to maximize efficiency of each motion. Comprehend the various production formats and systems. Understand the necessity of synchronization in the division of labor. Distribute process to operator using fundamental rules in synchronization and line balancing. Calculate pitch time, identify bottleneck, and calculate organization efficiency. Certificate (trainee who passed both attendance and competency) Register at : E-mail: [email protected] [email protected] Tele : +855 23 88 34 35 Fax : +855 23 88 28 60 URL : www.gmac-cambodia.org

© Copyright 2026